Key points

- Digital image technology can bring objective measures to formerly subjective analyses of pulse quality

- If sensors could be made smaller and more robust they would have the potential to improve quality control on-farm and throughout the pulse industry value chain

- Sensors have the ability to evaluate new product traits for new pulse markets

The proverb that 'beauty is in the eye of the beholder' is more applicable to pulses than other grains. Unlike wheat, malting barley or canola, where quality is defined by proteins, carbohydrates, enzymes and fatty acid composition, pulses for centuries have been traded on their visual appearance and seed size. To this day, it is estimated that less than 10 per cent of pulses' market value is defined by an industry-standard objective measurement.

Nonetheless, it is important to be able to quantify the market value of pulses to ensure growers are paid appropriately for their produce.

Dr Joe Panozzo and his team at Agriculture Victoria's Grains Innovation Park at Horsham have extensive expertise in evaluating grain quality to provide objective guidance to plant breeders selecting new varieties. Recently, they have been investigating the application of digital image analysis to determine quality traits in pulses.

"We aim to develop objective measures of quality to be used in each stage of the value chain from plant breeding and post-harvest through to the point of delivery and also by the export marketers," Dr Panozzo says.

Digital technology

Historically, pulse quality has been measured using grain-sieving tests to determine seed size, or assessed visually for colour, contamination or defects. This meant a high level of subjectivity. Equally, inconsistencies in determining quality are often encountered by growers when delivering grain to receival points, where they unexpectedly find their grain has been downgraded.

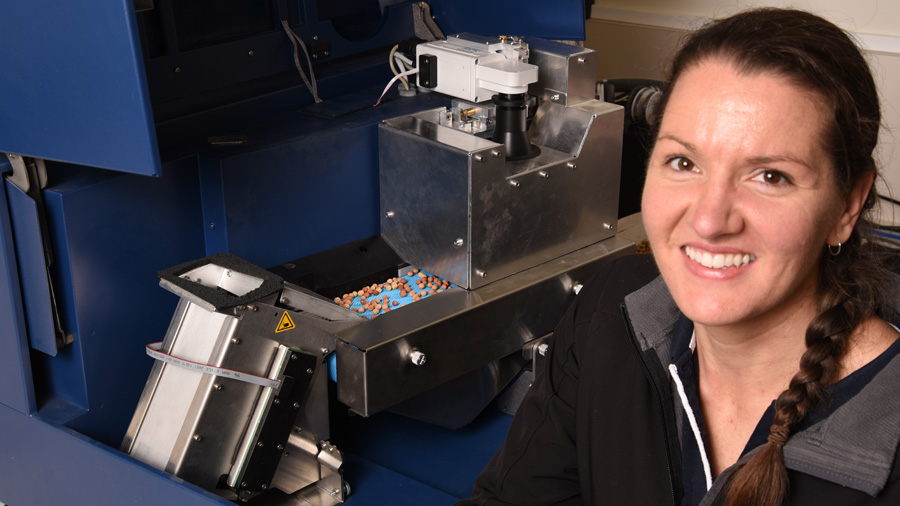

Agriculture Victoria research scientist Linda McDonald with a grain image analyser. Photo: Agriculture Victoria

Technological advances in digital sensors that measure the spectral response to light reflected from plants and grains are now set to revolutionise agriculture.

It is already part of our lives, within our homes and on-farm. Examples of this can be seen in the advance of digital cameras, smartphones and apps. Their application is only limited by our imagination.

Digital image analysis is a two-step process whereby grain images are captured using high-resolution cameras and the data interrogated using mathematical algorithms based on a combination of pattern recognition and colour measurements within each pixel.

In agriculture, the health and quality of crops and grains are initially perceived by their visual appearance, which is important for market acceptance. However, underlying this perception is chemical composition, comprising carbohydrates, nitrogen compounds including proteins and a wide range of metabolites.

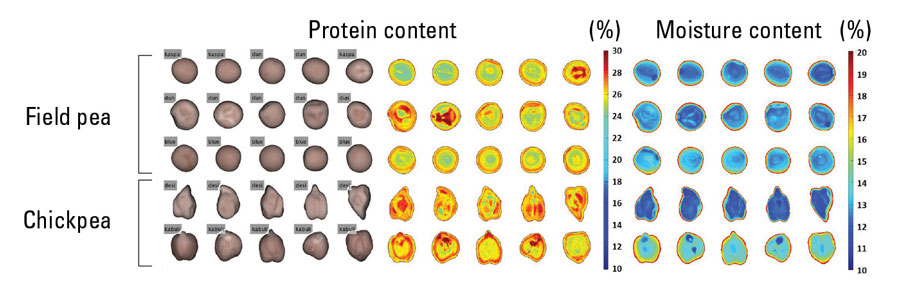

These compounds have unique spectral signatures that can be quantified through mathematical models or algorithms developed using reference libraries of quality trait data. These models provide distributions of the compositional and visual traits of the grain, the overall colour and the market-grade classification (Figure 1).

Figure 1: Model predictions demonstrating variation in protein and moisture percentage in field pea classes (Kaspa, Dun and Blue) and for Desi and Kabuli chickpeas.

Source: Agriculture Australia

Grains industry impact

Most of the pulses produced in Australia are exported to the Indian subcontinent, the Middle East, Turkey and north Africa and consumed by many ethnic groups. While each country may utilise pulses differently, common to all is the assessment of quality based on the colour of the seed and split pulse, and cooking quality.

"One of the objectives of the pulse-breeding program is to ensure the quality traits of new varieties align with the preferences defined by the export markets and that the quality is equal to or better than the pulses produced by Australia's competitors," Dr Panozzo says.

To more accurately and efficiently assess pulse quality, GRDC and Agriculture Victoria have invested in a project to develop digital image analysis and supporting algorithms as tools to measure quality.

The project involved measuring and characterising thousands of individual seeds and their corresponding images and using advanced programming and machine-learning methods (often referred to as artificial neural networks) to develop algorithms and classification models. Part of this work was undertaken by PhD student Linda McDonald.

"The outcome is that we can now pour a scoop of grain into a multispectral scanner and within minutes the data output is equivalent to what a laboratory technician would have taken an hour to produce. This new method of quality assessment also has applications in better characterising germplasm in the Australian Grains Genebank, which would assist plant breeders in their search for improved germplasm," Dr Panozzo says.

We aim to develop objective measures of quality to be used from plant breeding and in each stage of the value chain; from post-harvest through to the point of delivery and also by export marketers.

Benefit for growers

"Our goal has always been that the grains industry and growers will benefit from this research and that advances in technology through sensor miniaturisation will facilitate their adoption on-farm in augers, seed cleaners and silos."

This will require the sensors to be more robust so that they can operate in a non-laboratory environment with fluctuating temperatures and dusty conditions.

"Growers already have access to on-harvester protein analysers for cereals and the work we are doing will complement these technologies by using spectral signatures that best align with pulse quality traits, and develop in-field algorithms and robust sensors that can be incorporated in post-harvest storage and segregation," Dr Panozzo says.

Assist developing markets

Another aspect of pulse quality is associated with seed composition, rather than visual or physical traits. These specifications diverge from those of traditional export markets but are driven by growing interest in pulses as a source for plant-based proteins and their reputed metabolic benefits.

Field pea diversity in the field pea breeding program. Photo: Agriculture Victoria

Developing varieties for higher protein or specific protein composition has not been a breeding objective as it is known that the protein percentage of pulses is twice that of cereals. Dr Panozzo believes it is possible to further increase the protein percentage of pulses by better exploiting available germplasm.

"We have now developed non-destructive near-infrared tests which we can use to test lentils, field peas and chickpeas for protein percentage and carbohydrate composition. This provides us with an additional breeding tool outside current market specifications to meet the future demand for pulses as a source of plant-based proteins," he says.

To better understand the complexities of pulses, the team has recently acquired a high-resolution, shortwave infrared hyperspectral imaging system, which can measure the spectral response of biologically important compounds in the seed. Each pixel within the seed image has a unique spectral signature, which can be used to develop models and create a topographical map of each individual pulse seed's composition.

From this they hope to better understand other aspects of pulse quality including the vexing question of cooking quality, which is related to the hardness of the seed and the requirement to hydrate seeds overnight.

"We are not sure if seed hardness is purely a genetic trait or if agronomy and environmental conditions also have an effect. We do know seed hardness may affect germination efficiency and seed vigour and so in addition to hardness being a cooking trait, it may also be an agronomic trait, and we envisage this technology may help unravel this puzzle," Dr Panozzo says.

More information: Dr Joe Panozzo, 03 4344 3129, joe.panozzo@agriculture.vic.gov.au