A National Grower Network-driven project that measured harvest losses in Western Australia found that they exceeded benchmarks for all crops assessed in the 2021 and 2022 seasons. When extrapolated to the WA crop area and multiplied by average commodity prices at harvest, the losses were estimated to be more than $300 million each season.

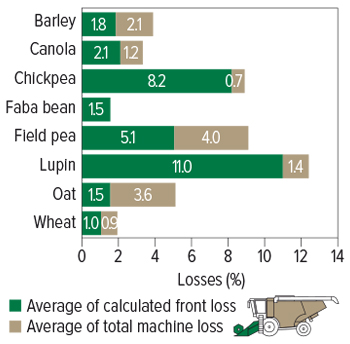

The study examined losses as growers harvested across 75 sites in all port zones. Losses were estimated for wheat, barley, oats, narrowleaf lupin, field pea, chickpea and faba bean crops (see Figure 1). The value of the harvest losses was also estimated (see Table 1).

Figure 1. Losses by front and machine losses by crop.

Source: Grower Group Alliance

Table 1. Average total losses in value terms by crop type in 2022.

Yield averages as measured t/ha | Nominal average harvest commodity prices ($/t) | Average front + machine losses (%) | Average value measured lost ($/ha) | |

|---|---|---|---|---|

Barley | 5.03 | 295 | 3.9 | $57.35 |

Canola | 2.64 | 755 | 3.3 | $66.07 |

Chickpea | 1.06 | 520 | 8.8 | $48.89 |

Faba bean | 3.00 | 470 | 1.5 | $21.61 |

Field pea | 2.10 | 450 | 9.0 | $85.23 |

Lupin | 2.66 | 345 | 12.3 | $112.90 |

Oat | 4.58 | 305 | 5.0 | $70.08 |

Wheat | 3.90 | 353 | 1.9 | $26.50 |

Harvest loss measurements were made using drop trays to capture front and machine losses. The analysis included information about crop and ambient conditions, front losses (including front type, set-up and any additions or modifications such as knife guards or air reels) and the machine losses (with consideration to travel speed, rotor clearances, fan speed and sieve settings). There was also consideration for any weed seed control strategies.

The study found that in 2022, total loss figures for growers who owned trays was about 0.8 per cent lower than those who did not own trays. Of these losses, it was suggested that up to half could be recovered with adjustments to harvester settings, machinery sensor calibrations and equipment modifications.

Extension activities run within the project raised awareness of these issues and provided recommendations through consultant and grower networks.

An immediate outcome has been increased confidence to invest in equipment to measure losses. The project is supported by harvester set-up workshops which show growers how to adjust their harvester settings and better understand the benefits of specialist equipment.

Among the recommendations for machinery settings are:

- When optimising harvester performance, the best practice is to change one machine setting (or make one adjustment) in isolation before retesting to evaluate the impact of that change. Determining which component or adjustment should be made requires experience.

- There appears to be merit in threshing system optimisation with aftermarket accessories but further work is required to validate these findings.

- Arguably offering additional throughput and increased field efficiency, average losses measured with stripper fronts are significantly higher than draper fronts in cereals. Growers should consider this when calculating the benefits and costs of using a stripper front, for example in a strip-and-disc system.

- Cereal growers should also set the reel to penetrate the crop only enough to lay cut material on to the draper belt. This prevents the reel from knocking grain out of the head and on to the ground.

- Pulses can be particularly problematic for front losses with mitigation options including knife, reel and air adaptations (although the economics on these adaptations is still pending). While lentils are an emerging crop in WA, measured losses indicate a strong case for the use of an air reel to minimise losses.

- An adjustable knife front improved field efficiency in canola and barley, reducing losses.

The project was led by the Grower Group Alliance, with Primary Sales Australia, the WA Department of Primary Industries and Regional Development, Facey Group, Corrigin Farm Improvement Group, Stirlings to Coast Farmers and the Liebe Group. Project data has been uploaded to the Online Farm Trials database.

More information is available at the Grower Group Alliance website.

For more detailed coverage of these projects, see also the September issue of GroundCover.

More information: Daniel Kidd, [email protected]; Ben White, [email protected]