Key points

Take time to be aware of factors affecting harvest loss:

- crop type and variety selection

- ambient conditions

- seasonal conditions

- paddock history

- operator experience

- crop conditions

- harvester specifications

- maintain records – crop yield, machinery performance, seasonal conditions

Take time to reduce losses by:

- measuring both front and machine losses using drop trays

- referring to industry benchmarks for harvest loss by crop type

- making single changes at a time and reassessing loss each time

- calibrating loss monitors after achieving acceptable loss levels

- reviewing front type

- considering other modifications

- building capacity to assess losses

- reviewing logistics and need for additional equipment – chaser bins, trucks, storage

Hit the ‘sweet spot’

- the point where harvest capacity and harvest losses are acceptable

Timing is critical when it comes to harvest and machinery expert Ben White says checking that your harvester is operating optimally can actually save time as well as delivering significant financial gains to growers.

“A second season of harvest loss assessments from a GRDC-invested project by the Grower Group Alliance is still showing that Western Australian growers are missing out on valuable yield,” Mr White says.

“Harvest is a dynamic process and will vary every season for every crop and with different operators, so each season it is imperative to measure and assess losses and alter machinery set-up to ensure losses are acceptable. The time taken to do this pays dividends.”

The 2022-23 results from the project are in line with data generated from the previous season’s harvest results, where more than $300 million of grain was potentially lost during the harvest process in Western Australia.

Harvest losses

“As per industry guidelines – established by theSociety of Agricultural Engineers, Prairie Agricultural Machinery Institute and Kondinin Group – a less than one per cent yield loss in cereals should be achievable, with less than two to three per cent in canola depending on the conditions,” Mr White says.

Harvest losses in the second season of the project generally exceeded acceptable thresholds for all crop species except wheat and validate what was found in the previous season (Table 1).

“It demonstrates a missed opportunity, which growers work hard throughout the season to produce.”

Variety selection, seasonal conditions, paddock history, operator experience, crop conditions, harvester specifications and harvest logistics all play a role in how effectively a crop is harvested and losses are optimised.

Table 1: Losses from 2022 study (combined front and machine) by comparison with 2021 data. Arrows indicate an increase or decrease.

Number of measurements taken | 2022 Average total losses (%) | 2021 Average total losses (%) | Year on year variation | |

|---|---|---|---|---|

Barley | 30 | 3.9 | 4.6 | -0.7 |

Canola | 44 | 3.3 | 3.2 | 0.1 |

Chickpeas | 11 | 8.9 | 7.2 | 1.7 |

Lupins | 24 | 12.4 | 11.2 | 1.2 |

Oats | 12 | 5.1 | 7.3 | -2.2 |

Wheat | 30 | 1.9 | 2.0 | -0.1 |

Source: GGA

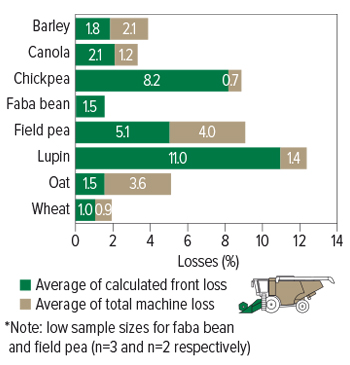

For a second year in succession, front losses were found to exceed machine losses for all crop species except barley and oats, and losses from stripper fronts were often far higher than for other front styles. Harvest losses for grain legumes, particularly lupins, continued to exceed those of cereals and canola (Figure 1).

Figure 1: Percentage of front and machine loss by crop type for the 2022-23 season*.

Source: GGA

The project was coordinated and led by the Grower Group Alliance, with the data analysed by Mr White, who is a harvest specialist.

The on-ground harvest loss measurements were taken in 65 paddocks for eight crop species by three grower groups (Liebe Group, Corrigin Farm Improvement Group and Stirlings to Coast Farmers) and a private consultant in Esperance.

Know your losses

Environmental conditions can play a large part in a crop’s harvestability. Assessing the crop’s maturity, moisture content and prevailing heat – and planning the best time of day or night to harvest – can make a start to reducing losses.

“Visual assessment of grain on the ground does not provide the accuracy needed for informed decisions about machine set-up and setting changes,” Mr White says.

Steps to reducing harvest losses start with harvester operator loss quantification and subsequent loss sensor calibration.

We found that growers who were measuring losses with drop trays had lower loss figures for high-value crops.

“However, unfortunately, the proportion of growers using drop trays are in the minority in WA, with fewer than four in 10 growers utilising them.”

To optimise the performance of a harvester, it is recommended to sequentially change a single machine setting, then retest the losses and refer to industry benchmarks.

“Whilst many state-of-the-art harvesters now have the ability to automatically sense losses and adjust their settings on the go, they actually still need to be ground-truthed and calibrated for a given paddock and crop situation for the automation to adapt appropriately.

“Growers should keep in mind that there is a ‘sweet spot’ – a balance between harvester capacity (tonnes per hour) and losses that should be struck in any harvesting operation.”

Know your front

Front losses were also surprisingly high for 2022, exceeding measured machine losses in all crops except for barley and oats (Figure 1).

Growers may have been ‘pushing’ harvesters beyond acceptable loss benchmarks due to the sheer bulk of crop to get through for the 2022 season in Western Australia. The study’s measurements showed that, in particular, front losses are in need of attention.

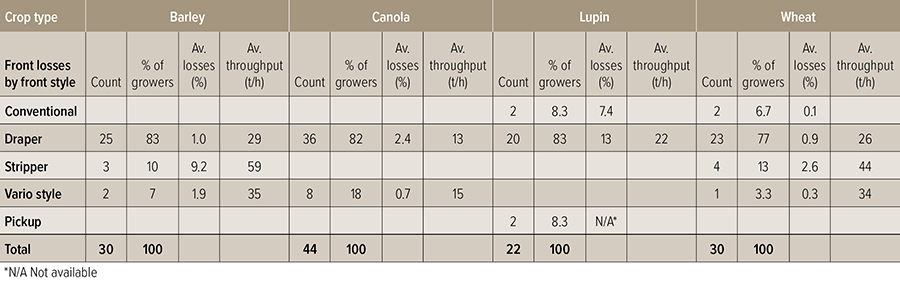

Of note, while offering significantly higher throughput in wheat and barley, losses incurred by stripper fronts were higher than other front styles.

“Stripper fronts tend to work best in very specific crop conditions. Cereal crops sown on narrow rows – less than 250 millimetres spacing – or harvested on an angle to keep the front full.”

A harvester equipped with a stripper front can harvest at between 50 and 70 tonnes per hour because there is far less material other than grain to process through the machine, which also means there is lower fuel consumption, less wear and tear and lower maintenance costs.

Significantly increased field efficiency was observed when using stripper fronts in cereals (69 per cent increase in wheat and 100 per cent increase in barley) but average losses measured were several times higher than losses from draper fronts.

For example, for barley the average throughput for a stripper front was 59 tonnes per hour compared to 29 tonnes per hour for a draper front, but the harvest losses were on average 9.2 per cent compared to one per cent for draper fronts (Table 2).

“Growers need to weigh up the trade-off between increased field efficiency of stripper fronts with other agronomic implications as well – for example stubble handling and seeding – when determining the benefits and costs of using a stripper front, for example in a strip-and-disc system,” Mr White says.

“With the improved field efficiency and speed of harvest, growers also need to consider other aspects of harvest logistics, for example chaser bin and grain storage capacity.”

Adjustable knife fronts demonstrated improvement in throughput in canola crops but with a significant reduction in front losses, making a strong business case for their use.

Draper fronts can limit harvester capacity in difficult-to-harvest crops including canola, so it is likely adjustable knife fronts will increase in popularity because they offer superior feeding and crop flow for direct harvesting.

The average throughput for adjustable knife fronts in canola was 15t/hr, compared to 13t/hr for a draper front (a 15 per cent improvement) and the loss was 0.7 per cent compared to 2.4 per cent (Table 2).

Table 2: Front style, average throughput (tonnes per hour) and losses (%) by crop.

Source: GGA

“Applying the figures collected to a back-of-the envelope calculation for return on investment of purchasing an adjustableknife front could stack up for some growers,” Mr White says (see sample calculation).

“Although purchasing adjustable knife fronts may be challenging at present due to import delays, there are reported cases of growers successfully sharing the use of an adjustable knife front during harvest, usually set up on a dedicated harvester. Others have shifted to harvesting their whole program with them exclusive of a draper front.”

Front losses through pod shattering for legumes was shown in 2022 to be particularly high, similar to the previous season findings.

“This can be reduced by ensuring the knife and guards are in good operating condition. Accessory sweeps over the knife or guard adaptations or extensions can also pull material into the front over the knife. Solutions can vary in their effectiveness by season, ambient conditions and by crop variety.”

Sample calculation

Adjustable knife front purchase back-of-the-envelope

The following calculations have been provided by Ben White and Peter Newman from Planfarm as an example demonstrating the financial benefit of purchasing an adjustable knife harvester front when applying the figures from the GGA-compiled data and a long-term average farmgate price of canola at $600 per tonne. This scenario explores the cost of having an additional front for canola but could be extended for those growing pulses. It also assumes the draper front is retained for cereals, but some growers have moved across to adjustable knife style fronts for all crops including cereals. Additional data relating to cereal losses with adjustable knife fronts is needed to evaluate this scenario.

Reduction in canola losses

Measured reduction in losses: 2.4 per cent (draper) to 0.7 per cent (adjustable knife style) = 1.7 per cent

Average canola yield: 2.64t/ha

Potential reduction in losses per hectare with adjustable knife style: 45 kilograms/ha @ $600/t (long-term farmgate harvest price) = $27/ha

Increase in throughput

Gains through expedited harvest throughput

Harvester running cost per rotor hour = $750/hr (all costs including chaser)

Throughput improvement with adjustable knife style front = 15 per cent

Additional throughput saving $113/hr or about $20/ha @ 15t/hr

Nominal outlay for adjustable knife front $200,000

Total loss reduction and throughput gains: $47/ha

Therefore, the total area of canola for full payback on adjustable knife style front purchase in canola of comparable yield (2.64t/ha): 4255ha

Alternatively, looking at this scenario from a cashflow perspective, financing a $200,000 front over five years at 6.5 per cent hire purchase, repayments would be about $48,000 per year. This means that an average of just over 1000ha of canola per year would be where the purchase becomes break-even.

Other modifications

Mr White says the study investigated harvesters as delivered and with modified concave and rotor set-ups and there appears to be merit in threshing system optimisation with after-market accessories.

“Rather than pulling a header out of the box and using it as is, it may well be beneficial to take some time to consider and measure the impact of changes and modifications.

“Loss reductions and capacity increases have been demonstrated in third-party preliminary research but an investment in further work in this space is required to validate this work more widely.”

Build your capacity

Daniel Kidd from the Grower Group Alliance (GGA) says an experienced operator can be invaluable when it comes to harvest, “but we have also demonstrated that after two successive seasons, taking the time to assess harvest loss and make modifications to your harvester will pay dividends”.

Mr Kidd has been managing the Harvest Losses project and says there are several grower groups in Western Australia, including Liebe Group, Corrigin Farm Improvement Group, Stirlings to Coast Farmers and Facey Group, that have been equipped with sets of drop trays and trained in their use through the project.

“These are available for grower use and some grower groups may also be able to provide assistance with loss assessment,” he says.

Linking grower group staff with experienced industry professionals like Ben helps build capacity in our regions and for our wider GGA network.

In parallel to the Harvest Losses project, Primary sales have managed the GRDC’s harvester set-up forums for the past two seasons featuring Ben White as an independent presenter at many of these.

Advice and assistance can also be sought via the Twitter handle @harvestloss.

More information: Daniel Kidd, daniel.kidd@gga.org.au; Ben White, ben@bmwhite.com.au