Snapshot

Grower: Graeme, Heather, Tristan and Lisa Baldock

Farm name: Karinya Ag

Location: Buckleboo, South Australia

Crops grown: Wheat, barley, field peas and canola

Property size: 6000 hectares

Soil types: Red-brown sandy loam, grey sandy loam

Soil pH: 8.0 to 9.0

Average annual rainfall: 295 millimetres

Deep ripping combined with liquid nutrient injection could be the recipe needed to remediate Tristan Baldock's Mallee-type sands by 2029.

The Buckleboo, South Australia, grower is drawing on lessons from hosting research trials on his family property from as far back as 2002 to resolve constraints such as a hardpan layer causing stunted root growth, in addition to water repellency on the surface.

“The real driver for our efforts is due to our location being considered an unreliable rainfall zone 100 kilometres north of Goyder’s Line,” Tristan says.

“We know our climate here is likely to get drier rather than wetter in the future and we know we need to bring more life into our soils, because they are a living system.

“We’re working to achieve more with less. We could always buy more land to look for gains, but that land has to be physically managed, so instead of getting bigger we’re investing in having better soils.”

The Baldocks have had Buckleboo Farm Improvement Group (BFIG) trials and projects with GRDC investment on their property informing their efforts.

The two GRDC projects providing the most inspiration are the CSIRO-led ‘Increasing production on sandy soils in low and medium-rainfall areas of the southern region’ (the sandy soils project) and the ‘Improving sustainable productivity and profitability of Mallee farming systems with a focus on soil improvements’ initiative. The latter project is part of the strategic joint investment between GRDC and the South Australian Research and Development Institute (SARDI).

These trials have been looking into deep ripping as a method to address common issues associated with sandy soils, such as low water-holding capacity, poor fertility, compaction, leaching of nutrients, patchy yield response and susceptibility to erosion.

Ripping equipment

The sandy soils research has involved the use of a six-metre-wide Paxton Plow Co soil renovator fitted with Liquid Systems (SA) Spiker Banding Buddy equipment.

This equipment was bought by a local syndicate of four growers to build on deep-ripping responses observed on their properties. The machine has 13 outlets mounted on tynes at 450-millimetre spacings to simultaneously rip the soil and inject trace elements. The system distributes a nutrition stream through the profile as the soil collapses down the back of the trench via an inclusion plate, which is bolted to the ripping tyne.

Last year’s trials involved ripping at various depths from 350 to 450mm with a number of nutrition treatments.

The control plot, which received only the base sowing fertiliser applied to all sites of 60 kilograms per hectare of diammonium phosphate, 20 litres/ha liquid urea and ammonium nitrate, 300 grams/ha of zinc and 50g/ha copper and no ripping, yielded 1.6 tonnes/ha.

The most successful nutritional mix of 20kg/ha of nitrogen, 17kg/ha phosphorus, 0.6kg/ha potassium, 10kg/ha sulphur, 1.2kg/ha copper and 0.6kg/ha manganese returned 2.24t/ha, which was a 650kg increase in yield.

Tristan says his most economic scenario going forward involved 450mm ripping with inclusion plates and a nutrition package that included nitrogen, phosphorus, sulfur, zinc and copper which cost $75/ha.

This scenario produced a yield increase of 580kg and the increased returns over the untreated plot paid for the entire ripping and nutrition process in the first year.

“We think there will be an ongoing yield benefit that will decrease over time, but we’re hoping to stretch that yield benefit out to at least five years,” Tristan says.

“If we have to do this treatment again in five years’ time then hopefully that will be the last time we do it, as we’ve promoted the development of improved soil structure through root channels and nutrition over time.

“Of course, the other part of the puzzle we haven’t looked at yet is how the crop rotation plays a part in improving soil structure.

“I think it will need a combination of cereal plants with lots of fibrous roots and perhaps plants like canola that have a bigger tap root.”

SARDI research

The soil amendment research conducted as part of the SARDI-GRDC strategic research partnership was expanded to include a site at Buckleboo in 2019 for the first time and is continuing in 2020.

SARDI research agronomist Brian Dzoma is running the trials alongside other field research conducted as part of the sandy soils project. Mr Dzoma’s research is looking to address compacted sandy soils and find the ideal ripping depth and width for yield response, duration of benefits and overall economic returns.

The Buckleboo location was in addition to similar sites established at Peebinga and Loxton in 2018. These sites examined deep ripping at various depths of up to 70 centimetres and tyne spacing widths of 30cm and 60cm.

“We’re trying to ameliorate compacted sands that restrict the plant about 20cm below the soil surface,” Mr Dzoma says. “Deep ripping loosens the soil profile, which should improve access to nutrients and moisture and increase crop productivity.”

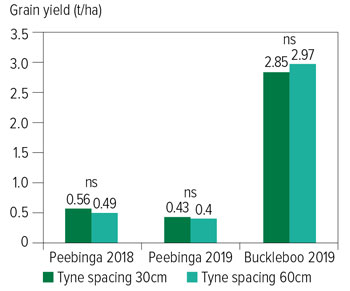

Figure 1: Tyne spacing yield response from 2018 and 2019 trials.

Source: SARDI

Mr Dzoma says the results from the first two seasons at Peebinga were skewed by dry conditions, but he is hopeful of a “kind” year in 2020 to reveal the full story for growers with sandy soils.

His research has already shown the width of tyne spacings makes little difference to productivity, with 60cm tyne spacing performing as well as 30cm spacing in all trials (Figure 1).

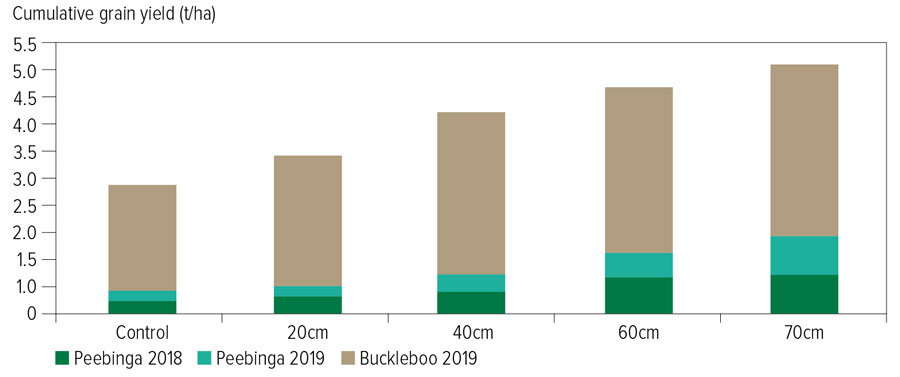

Instead, yield gains came from the depth of ripping (Figure 2).

“There is no reason for growers to use narrow 30cm ripping tyne spacings which require more horsepower and fuel, when the same yield benefit occurred from the wide 60cm spacing,” Mr Dzoma says.

“In fact, we observed significant issues with wind erosion, particularly in dry seasons, when ripping at narrow widths. The deeper we ripped, the more yield gain we observed.”

If underlying soil constraints such as sodicity, acidity and toxic elements such as boron are present, the benefits of deep ripping could be limited, so these subsoil constraints need to be understood before the ripping program starts.

Mr Dzoma says there is a trade-off between ripping depth and increased operation costs. An economic analysis to be compiled this year will allow growers to calculate the “sweet spot” of how deep to rip. He says growers can monitor how long it takes for sands to recompact after ripping by conducting regular soil penetration resistance measurements. This will determine when ripping might be repeated.

Figure 2: Yield responses by ripping depth in 2018 and 2019.

Source: SARDI

On-farm impact

After combining deep ripping and liquid nutrition for the first time in 2019, Tristan observed greater rooting depth and shoot growth under relatively dry conditions.

“The plants anchored in the soil better and still managed to finish, whereas crops grown in non-ripped soils had roots confined to the shallow depths and they were more susceptible to strong winds and dry conditions,” he says.

“I think it would be a great thing to see a significant increase in water-use efficiency and soils that are more friable – the kind of soils where you can push a penetrometer into the profile with one hand. That is where we are headed.”

The outcomes of this project are being delivered via the strategic research partnership between GRDC and SARDI in collaboration with the University of Adelaide. The GRDC-SARDI partnership has facilitated a range of projects which provide innovative research outcomes relevant to SA’s cropping zones and beyond.

More information: Tristan Baldock, 0447 282 622, tristan@karinyaag.com.au; Brian Dzoma, 0455 071 032, brian.dzoma@sa.gov.au