Key points

- Existing back-pressure data for aerating grain was largely developed in the Northern Hemisphere via studies that date back as far as the 1950s

- Flow rates vary depending on the back pressure exerted by different grain and storage systems

- A prototype test rig is under development to enable testing of local storage systems

New testing set to reveal back pressures for Australian grain under aeration.

Achieving sufficient airflow is essential for effective grain aeration, and back pressure – the resistance to airflow through the grain – is one of the important variables determining success. But much of the information used to determine aeration back pressure is outdated and was generated under Northern Hemisphere conditions.

To understand whether flow rates are sufficient to achieve cooling or drying, growers need to understand back pressure and fan performance curves, which can be difficult to find. To address these gaps, GRDC investment through the ‘Grain Storage Extension Project’ is evaluating Australian systems.

Understanding airflow

Grain aeration can be used to reduce grain temperatures or moisture content, making it a valuable tool to protect stored grain from deterioration and insect pests.

Aeration cooling has the potential to drastically reduce insect pest reproduction rates as well as preserve grain quality and germination. Aeration drying reduces grain moisture content to provide safe long-term storage of the commodity.

Typical aeration flow rates required for aeration cooling are about two to four litres per second for each tonne of grain in storage. Aeration drying requires much higher flow rates of between 15 and 20l/s/t.

Aeration fans are not typically supplied with performance curves, as performance depends on many factors including fan design and the ducting chosen to take air from the fan and diffuse it through the grain. When the fans are operational, the back pressure – or static pressure – exerted by the grain also plays an important role.

Back pressure depends on many factors including:

- the type of grain and its physical properties, including moisture content, size and shape. For example, aerating canola generates significantly more back pressure than larger, coarse grains such as sorghum and maize;

- the airflow rate – back pressure increases as the flow rate increases; and

- the depth of grain – the relationship between depth and back pressure is relative, with higher silos having higher back pressure for the same airflow rate.

Australian testing

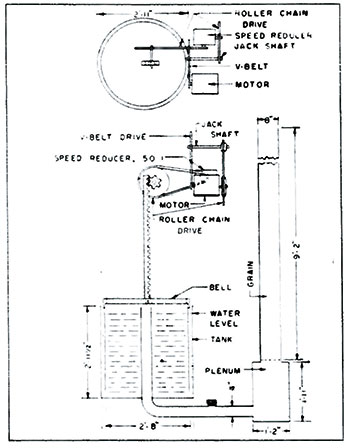

A comprehensive literature review of available information revealed that much of the currently referenced information relies heavily on research work done as far back as the early 1950s (Figure 1).

Figure 1: Much of the pressure data relied on today was developed for Northern Hemisphere grain storage systems and from as long ago as the 1950s. For example, this 1951 diagram demonstrates the equipment historically used to calculate back pressure in columns containing grain.

Source: diagram by Claude K Shedd, Agricultural Engineering, Journal of the American Society of Agricultural Engineering, September 1951.

It also identified that almost all of the relevant back pressure research to date has been conducted in the Northern Hemisphere, focused on grains, varieties and airflow rates that may not be suitable for the Australian situation.

These findings are disconcerting, but helpfully the review identified several methods of determining back pressure that will help the Australian team develop test equipment capable of capturing back-pressure data under a range of airflow rates and grain depths.

The next stage involves the design and prototyping of a modern test rig to capture back pressure data. Based on similar test equipment identified in the literature review, the rig will be adapted to suit Australian grains and airflow rates used under typical grain storage environments.

The rig will use high-precision instrumentation for measuring back pressure and airflow, with variable-speed, brushless, DC-driven, backward-curved blowers to push air through columns of a range of grains.

Results generated with the grain types typically stored in Australia will enable the team to ground-truth the local relevance of the existing data from the Northern Hemisphere. The research will also explore back-pressure data for crops more traditionally grown in northern Australia, including sorghum, mungbeans, soybeans and maize.

More information: Ben White, 1800 WEEVIL, info@storedgrain.com.au