Key points

- Researchers exploring hyper-yielding wheat have demonstrated new grain yield benchmarks during the past three years

A red feed wheat variety grown at Millicent, South Australia, in 2021 yielded 12.74 tonnes a hectare - Hyper-yielding crops require high levels of starting soil nutrition built through effective rotation that includes oilseeds and legumes

- In trials across five high-rainfall locations, closing the wheat yield gap depended on proactive fungicide application

Researchers exploring the ‘must-haves’ for growing hyper-yielding wheat have confirmed existing knowledge, set new grain yield benchmarks and unearthed a few surprises.

Three ingredients confirmed as essentials for growing hyper-yielding wheat include sowing a high-yielding variety into a fertile paddock and keeping it disease-free.

But GRDC Hyper Yielding Crops project lead Nick Poole, from Field Applied Research (FAR) Australia, says work across five states also uncovered some surprises.

“If you told me three years ago that our highest-yielding site on mainland Australia would be Wallendbeen in southern New South Wales, I wouldn’t have believed you,” Mr Poole says.

“While our site at Millicent in South Australia grew the highest wheat yield in 2021, overall, Wallendbeen – with its 480 to 500-metre elevation, red ferrosol clay loam soil and pasture/canola/wheat rotation – was consistently our highest-yielding site during the past three years.”

Mr Poole, who recently celebrated 40 years in grains research, says Wallendbeen’s secret to success is its high altitude, which keeps crops cool during the critical period.

“In 2020, the highest-yielding variety at Wallendbeen produced 10.84 tonnes of wheat per hectare, while in 2021 it was 11.66t/ha and in 2022 it was 11t/ha,” he says.

“They were all red feed wheat varieties and were way ahead of the milling wheat varieties.

“With an average growing season rainfall of 500 to 600 millimetres from 2020 to 2022, grain production at Wallendbeen was not limited by rainfall to the same extent as from 2017 to 2019.

“We acknowledge that 2020 to 2022 was an ideal period to examine the upper yield boundaries.”

Regarding the other GRDC Hyper Yielding Crops sites, Mr Poole says his team’s research indicated grain yields of more than 11t/ha were possible around high-rainfall areas such as Gnarwarre in southern Victoria, Millicent in SA and Hagley in Tasmania.

“In Western Australia, seven to 9t/ha has been demonstrated at FAR Australia’s Crop Technology Centres near Frankland River and Esperance.”

The critical period

Mr Poole says yield potential is driven by favourable conditions three to four weeks before flowering and 10 days after flowering.

“We need bright, sunny days with cool temperatures in the second half of stem elongation.

“Scientists refer to this as the photothermal quotient or the cool-sunny index, which is calculated by dividing daily solar radiation by average daily temperature.

“If we can boost growth during this critical period for yield determination, grain number is likely to be high, which is beneficial because there is a correlation between high grain number and high yields.

“While head number contributes to high yields, there is a limit to how head or tiller number can be used to increase yield.

“Generally, for 10 to 15t/ha crops, 500 to 600 heads/m² is likely to be adequate to fulfil grain yield potential.”

Yield potential

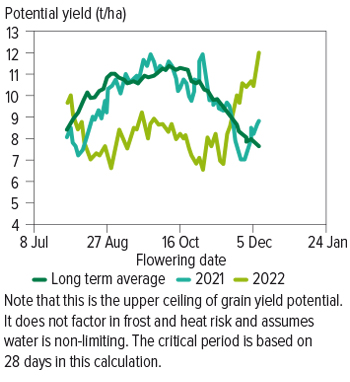

Knowing that the photothermal quotient (a measure of light and temperature) is important for establishing yield potential, Mr Poole’s team was disappointed when they calculated yield potential for display at the mid-October field day at Wallendbeen in 2022 (Figure 1).

Figure 1: Long-term grain yield potential and the relationship with flowering date at Wallendbeen, NSW, based on the photothermal quotient compared with actual 2021 and 2022 yields.

Source: Poole, N., et. al. (2023) Hyper yielding cereal agronomy – key levers and their interactions: varieties, nitrogen and lessons learnt. Proceedings of the 2023 Wagga Wagga GRDC Grains Research Update

“Figure 1 shows that based on an optimum flowering date of 10 October, the photothermal quotient for 2022 was considerably lower at Wallendbeen, indicating that grain yield potential would be significantly reduced in 2022,” he says.

“Now, remember that the photothermal quotient is calculated by dividing light by temperature. Temperatures in 2022 were about normal, but solar radiation was reduced by cloud cover in such a high-rainfall year. This acted as the handbrake on yield potential.

“We also found that 20 to 25 October was the sweet spot for red feed wheat flowering in terms of the critical period from 2020 to 2022.

“Sowing a wheat variety in its correct window is necessary to flower at just the right time to minimise frost, heat and moisture stress.

“But in high-yielding crops, where frost and heat stress are less problematic, optimising the flowering date for moisture and the photothermal quotient enables us to improve growth in the critical period for maximising grain number.”

Realising yield potential

Mr Poole says that once the potential for high grain numbers is established during the critical period, the crop needs conducive conditions for grain fill.

“For example, a slow-developing wheat variety could benefit from more-favourable growing conditions associated with a later flowering and a critical period with long sunny days and temperatures that are not excessive,” he says.

“Such conditions might maximise final harvest dry matter and growth during the critical period, but not final grain yield as conditions are too hot to maximise grain fill after flowering.

“We observed this at our five trial sites relative to the optimum flowering periods for those locations.

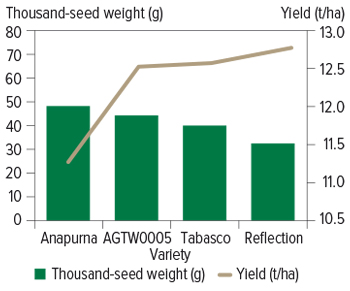

“In 2021 at Millicent, SA, the highest yield recorded in the project so far – 12.74t/ha – was achieved with a red feed wheat variety called Reflection from the UK.

“Traditionally, this variety was considered too slow for the Australian mainland high-rainfall zone. However, in 2021, the mild spring and summer grain fill period allowed this variety to complete grain fill under more-optimal conditions – something not typically observed.

“The indication that higher yield was underpinned by more grains per unit area was demonstrated by considerably smaller seeds and a lower thousand-seed weight for Reflection (Figure 2).”

Figure 2: Relationship between highest-yielding wheat varieties in the HYC elite screen and thousand-seed weight – Millicent SA 2021.

Source: Poole, N., et. al. (2023) Hyper yielding cereal agronomy – key levers and their interactions: varieties, nitrogen and lessons learnt. Proceedings of the 2023 Wagga Wagga GRDC Grains Research Update.

Wheat crop nutrition

One of the most notable findings from the project relates to nitrogen fertiliser.

“But applying high-nitrogen fertiliser rates is not always the best option to achieve hyper-yielding crops.

“Hyper-yielding crops need to be supported by highly fertile farming systems where, as soon as the soil becomes warm and wet, soil nitrogen is available to feed big yields.”

Mr Poole says nitrogen fertiliser decisions need to be made by considering the:

- soil’s nitrogen mineralising potential;

- nitrogen carried over from previous years;

- starting soil mineral nitrogen; and n crop lodging potential, which may affect radiation efficiency.

“Replacing the nitrogen removed from high-yielding crops must be done to maintain a sustainable farming system.

“However, where there are high starting nitrogen and/or high mineralisable nitrogen pools, replacing what mineral nitrogen is removed with fertiliser nitrogen during the growing season is difficult without possibly impacting negatively on grain yield.

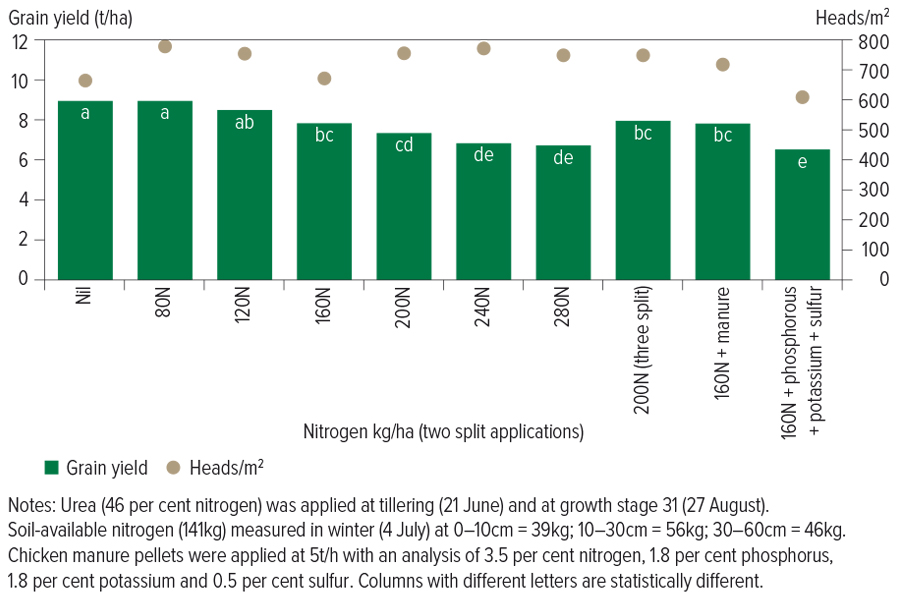

“Consider, for example, a mixed farming system based on legume pastures in rotation with a cropping phase that includes the winter feed wheat variety RGT Accroc that yielded 8.8t/ha (Figure 3).

Figure 3: Influence of applied nitrogen, manure and other nutrients on yield and head number at Wallendbeen, NSW, 2022. Columns denote grain yield and dots show heads/m2.

Source: Poole, N., et. al. (2023) Hyper yielding cereal agronomy – key levers and their interactions: varieties, nitrogen and lessons learnt. Proceedings of the 2023 Wagga Wagga GRDC Grains Research Update.

Table 1: In the far-right column in Figure 3, ‘160kg/ha of nitrogen + phosphorus + potassium + sulfur’, researchers applied additional nitrogen, phosphorus, potassium and sulfur to replicate manure application as in the ‘160 nitrogen + manure’ column.

| Product | Kg/hectare | Nitrogen | Phosphorus | Potassium | Sulfur | Date applied | |

|---|---|---|---|---|---|---|---|

| Monoammonium phosphate | 315 | 0 | 90 | 72 | 0 | Sowing | |

| Muriate of potash | 36 | 0 | 0 | 18 | 0 | 21 June | |

| Ammonium sulfate | 104 | 21 | 0 | 0 | 25 | 21 June | |

| Urea | 335 | 154 | 0 | 0 | 0 | 21 June | |

| Total | 175 | 90 | 90 | 25 |

Source: Poole, N., et. al. (2023) Hyper yielding cereal agronomy – key levers and their interactions: varieties, nitrogen and lessons learnt. Proceedings of the 2023 Wagga Wagga GRDC Grains Research Update.

“Figure 3 shows that applying nitrogen above 120 kilograms/ha reduced profit, while nitrogen above or equal to 160kg/ha also reduced yield.

“Despite applying the plant growth regulator Moddus Evo® at 0.2 litres/ha plus Errex™ 750 at 1.3L/ha at growth stage 31, higher nitrogen fertiliser rates increased head numbers and led to lodging during grain fill (data not shown), which reduced yield.

“When rainfall is not limited, fertile soil with a high soil nitrogen supply can mineralise enough nitrogen to achieve potential yield, as shown by the nil fertiliser rate in Figure 3.

“In fact, since 2016, in GRDC’s Hyper Yielding Crops trials, the optimum applied fertiliser nitrogen rarely exceeded 200kg/ha for the highest-yielding crops – even though the crop canopies on which these yields depended removed far more nitrogen than that at harvest.

“This indicates that the nitrogen supply in the hyper-yielding sites is most likely provided by nitrogen mineralised from soil organic matter before sowing and during crop growth.

“The 8.8t/ha yield from the nil nitrogen treatment in Figure 3 requires 250kg/ha of soil nitrogen/ha at an assumed efficiency of 70 per cent for humic soil organic matter and a similar efficiency for labile soil organic matter.

“These crop nitrogen recovery efficiencies are typically much higher than those achieved with fertiliser nitrogen, which is often reported at 44 per cent for the year of application and 66 per cent when measured over a three-year period.

“Consequently, the same 8.8t/ha yield supplied entirely by nitrogen fertiliser would require 400kg/ha of nitrogen, assuming a nitrogen efficiency of 44 per cent.

“High urea inputs are fine over several applications, provided they do not reduce yield.

“But remember, where good legume pastures are used in the rotation, it has been difficult to secure reliable grain yield responses in the year of application to rates of fertiliser nitrogen of more than 200 to 250kg/ha in hyper-yielding crops research.”

Protecting yield potential

Mr Poole says disease management is also important for growing high-yielding wheat.

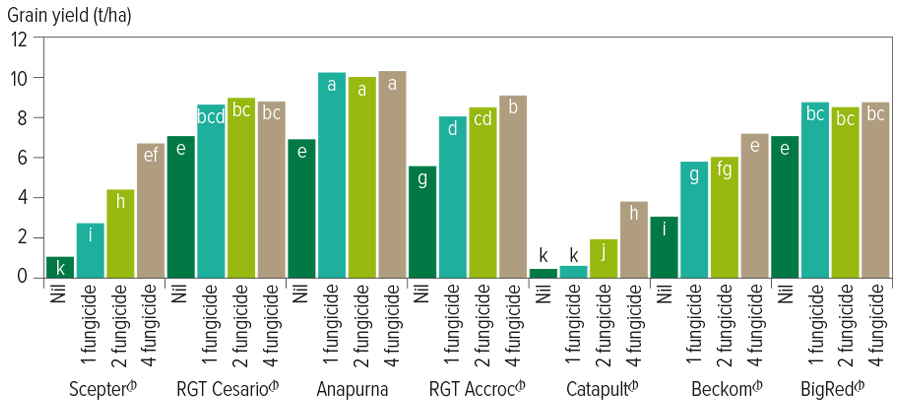

“At Wallendbeen, in 2022, grain yield was increased from less than 1t/ha to 10t/ha by combining the best disease management with the best disease resistance and yielding wheat variety,” he says.

At the trial, three milling varieties and four red feed wheat varieties were grown with four levels of fungicide protection (Figure 4):

- nil – untreated control;

- one flag leaf fungicide applied at growth stage (GS) 39;

- a two-spray approach with one at GS33 (third node) and the second at GS59 (head emergence); and

a four-unit approach combining flutriafol on the monoammonium phosphate, followed by three foliar sprays at GS31, GS39 and GS59.

Figure 4: The influence of the number of applied fungicide sprays on different varieties at GRDC’s Hyper Yielding Crops trial at Wallendbeen, NSW, 2022.

Source: Poole, N., et. al. (2023) Hyper yielding cereal agronomy – key levers and their interactions: varieties, nitrogen and lessons learnt. Proceedings of the 2023 Wagga Wagga GRDC Grains Research Update. Columns with different letters are statistically different.

In 2022, Mr Poole says the pressure from stripe rust and Septoria tritici blotch was so severe that not even the four-unit approach gave full control in stripe rust susceptible varieties.

“No variety had sufficient genetic resistance to be grown more profitably without fungicides,” he says.

“It’s also worth noting that poorer disease resistance ratings could not be fully compensated for by fungicides in these very high disease pressure circumstances.

“With Scepter, the response to the four-unit approach was almost 6t/ha, while with RGT Accroc, it was nearly 4t/ha.

For a third year in succession, despite low-level infection, the red feed varieties Anapurna, RGT Cesario and BigRed showed no significant yield advantage to four units of fungicide compared with one, resulting in significant savings.

“With RGT Cesario, stripe rust resistance was not complete, and a spray at GS31 reduced disease levels.

“It is worth noting that with the higher-yielding feed varieties, the response to fungicide was between 1.5t/ha and 3t/ha.

“The red feed wheat varieties have a level of resistance to disease pathogens that we can only dream of in some of our milling wheat varieties.”

If conditions are wet during stem elongation when the three upper canopy leaves emerge, Mr Poole says that fungicide application is essential to protect yield potential.

“The disease pressure was so intense during 2022 that fungicide timing and the strength of the active ingredients applied had significantly different effects on yield.

“Long ‘calendar gaps’ of control caused unprotected leaves to become badly infected in the period between sprays, with applicators depending on the limited curative activity of fungicides rather than their protective activity.

“If you spray early at tillering and then leave a large gap to flag, the top three or four leaves are unprotected. If you want to spray early, consider a strategy where you start at flag leaf and work backwards in three-week increments. Taking this approach will enable you to work out how many sprays you are likely to need in a season highly conducive to leaf diseases.

“The bigger the gap between those applications during stem elongation, the more you will likely rely on the fungicide’s curative activity, where the better option is actually preventative.

“Therefore, be aware of ‘the gap’ as stripe rust cycle times are impacted by temperature preference (12 to 20ºC).

“If maximum temperature divided by minimum temperature is about 15ºC, then you have excellent conditions for stripe rust cycling at about 10 days (infection to spore production). If this occurs in the stem elongation period, you have the potential for large infections and grain yield reductions.”

More information: Nick Poole, nick.poole@faraustralia.com.au