Key points

- Understanding and care are required to set up a mouldboard plough for effective soil inversion to manage weeds or water-repellent soil

- Mouldboard ploughing at speeds of 10km/h or more can result in topsoil being thrown too far across the furrow and reduce depth of topsoil burial

- Use of skimmers on a mouldboard improves the inversion effectiveness, with more of the topsoil being buried at 100 to 200mm depth, leaving less in the top 100mm.

Water-repellent topsoil and weed seeds can be managed by complete burial through strategic soil inversion.

By completely burying weed seeds, dramatic reductions in the viable seed bank can be achieved, particularly when herbicide-resistant weeds are present in a paddock and the seed bank is large.

In water-repellent soils, inversion buries the repellent topsoil and brings to the surface wettable subsoil, which aids water infiltration.

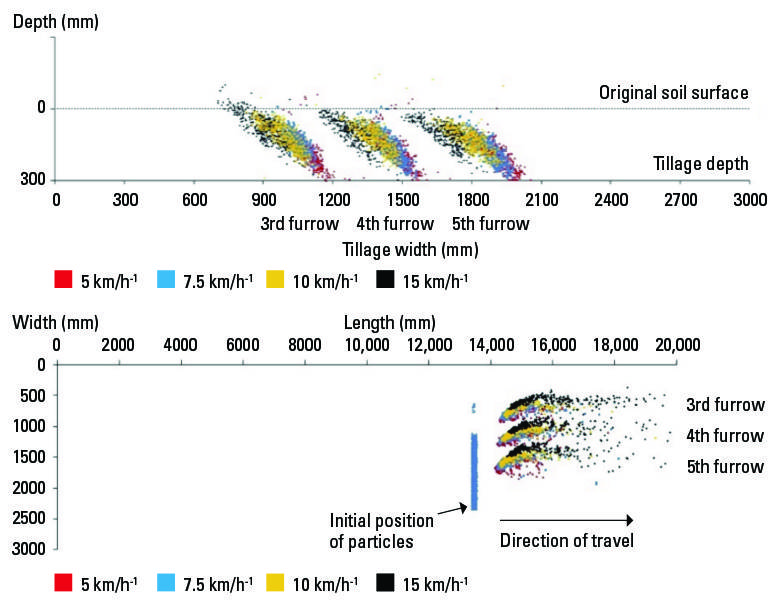

Figure 1 Comparison of topsoil particle movement from discrete element method simulations for the impact of ploughing speed at 300mm tillage depth and 50mm skimmer depths showing cross-sectional view of lateral movement to the left (top) and top view of forward movement in the direction of travel (bottom). Source UniSA

To effectively achieve these outcomes, in particular burial of herbicide-resistant weed seeds, the soil inversion needs to be as complete as possible.

Soil inversion is most commonly undertaken in Australia with mouldboard and modified one-way disc ploughs, but the soil conditions, plough set-up and operation can all influence inversion effectiveness.

Understanding the impact of plough set-up through use of field and simulation experiments has enabled us to define critical factors that increase inversion effectiveness.

Historic implement

Mouldboard ploughs are one of the oldest tillage implements and have been used around the world for thousands of years.

They are designed to invert soil and incorporate surface plant residues deeper in the profile.

The designs, shapes and sizes available have evolved over time to a point where all modern mouldboards are very similar in shape and form.

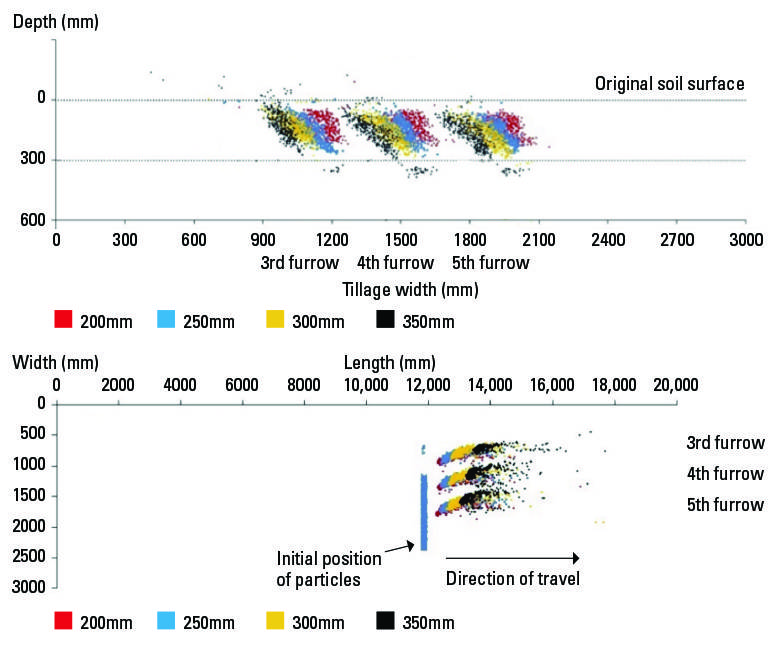

Figure 2 Comparison of topsoil particle movement from discrete element method simulations for the impact of ploughing depth at 50mm skimmer depth and 7.5km/h forward speeds showing cross-sectional view of lateral movement (top) and top view of forward movement in the direction of travel (bottom). Source UniSA

However, although they are efficient soil tillage tools, with common working depths in the range of 200 to 400 millimetres, they require understanding and care to use them effectively.

The main plough body folds and turns a strip of soil into the furrow created by the preceding plough body, therefore moving each furrow of soil to the side by one working furrow width.

There are several additional attachments that can be added to ploughs to improve the soil inversion and percentage burial; these include discs, coulters, trash boards and skimmers.

Skimmers are the most commonly used and are smaller plough shares that work ahead of each of the main plough bodies. They typically peel the top 50 to 100mm of the surface soil layer and direct it into the base of the furrow. Set-up of the mouldboard plough should be done properly before starting the operation to improve inversion efficiency.

Mouldboard plough sizes are defined by the number of boards working in series and hence the number of furrows created by the plough in any given pass.

Smaller ploughs with three to six furrows are often mounted by three-point linkage, in-furrow ploughs small enough so that tractors with single narrow wheels can be used and run in the furrow.

With semi-mounted ploughs, larger tractors can be used with dual wheels or tracks operating on-land (on untilled soil) and the plough mounted on a tool-carrier working in the furrow.

Semi-mounted ploughs can typically range from five to 14 furrows. Some smaller ploughs can be one-way but most mouldboard ploughs are reversible, allowing for 'up-and-back' ploughing.

Working speed and depth

Improved understanding of how plough set-up and use affect inversion can help provide guidelines to achieve the best result. In this respect, ploughing speed and depth are critical determinants of inversion effectiveness.

Discrete element method (DEM) simulations carried out by the Agricultural Machinery Research and Design Centre at the University of South Australia are providing insights into mouldboard plough operations.

They predict that, as speed increases, the depth of topsoil burial reduces. At higher speeds of 10 kilometres per hour or more the soil is essentially thrown further away from the plough body, higher up the furrow slope (see Figure 1).

Ploughing at a depth of 200mm is too shallow to effectively bury the topsoil, compared with ploughing at depths within the range of 250 to 350mm.

As the depth increases, the topsoil is moved further away from the plough body and further forward along the furrow in the direction of travel. This indicates the depths for which the mouldboards have been optimised.

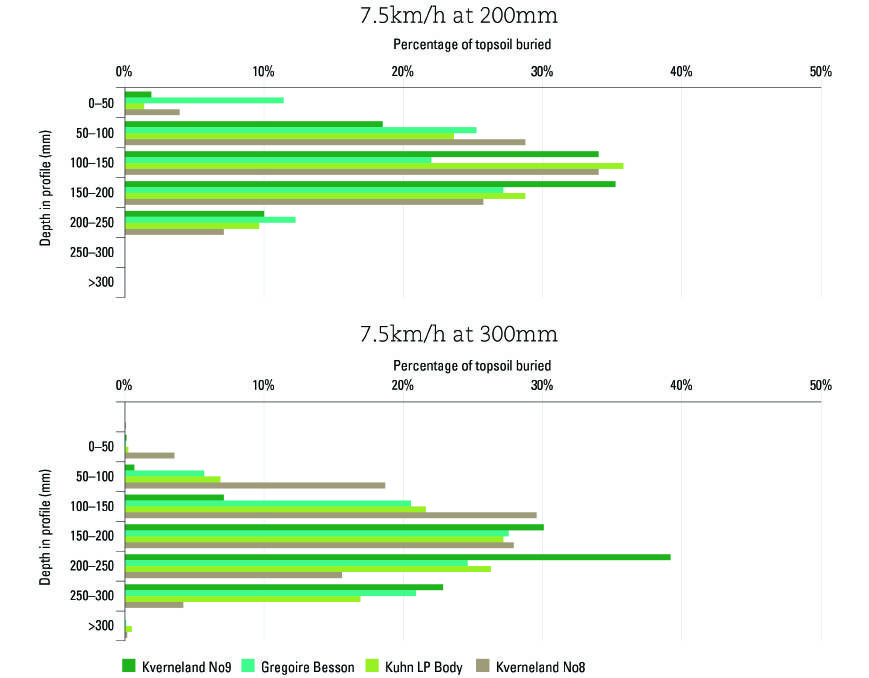

It should be noted that the effect of the speed is valid regardless of the brand of the mouldboard plough, although some mouldboard ploughs have been designed to work at specific depths. As a result, the working depth should be considered when purchasing a mouldboard plough (Figure 3).

Figure 3 Percentage of the topsoil buried into each 50mm layer down the soil profile from discrete element method simulations for various mouldboard plough brands and plough bodies at ploughing depths of 200mm and 300mm. Source UniSA

Skimmers

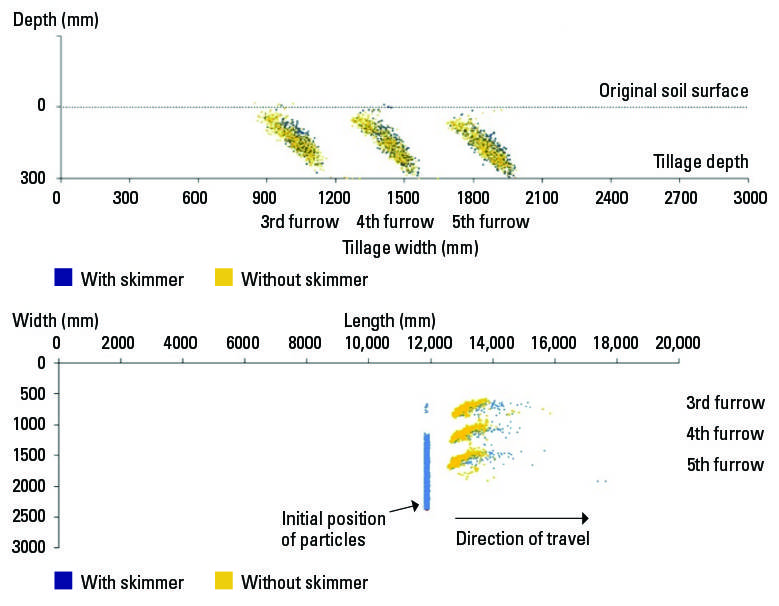

The role of the skimmer is to assist with surface trash burial. DEM simulations were used to assess inversion effectiveness with and without skimmers.

Skimmers were found to move more of the topsoil (top 100mm) into the 100 to 200mm depth layer within the ploughed profile, but did not influence deeper burial into the 200 to 300mm depth layer (see Figure 4). Use of skimmers only resulted in a small, four per cent increase in overall draught force. It was also found that placing of skimmers at more than 100mm depth does not improve topsoil burial but increases the draught force.

Figure 4 Comparison of topsoil particle movement from discrete element method simulations of the impact of using or not using skimmers at 300mm ploughing depth and 7.5km/h forward speed showing cross-sectional view of lateral movement (top) and top view of forward movement in the direction of travel (bottom). Source UniSA

Use of field-validated DEM has allowed variations in mouldboard plough set-up and use to be compared so topsoil inversion can be optimised.

Ploughing at speeds below 10km/h at the recommended depth with use of skimmers can result in more complete burial of weed seeds and water-repellent topsoil.

More information: Dr Stephen Davies, 08 9956 8515, stephen.davies@dpird.wa.gov.au; Dr Chris Saunders, 08 8302 3664, chris.saunders@unisa.edu.au