Key points

- Discrete element method (DEM) simulation shows mouldboard ploughs to be more effective than modified one-way disc ploughs at inverting soil.

- Treatment longevity and grain yield benefits from soil inversion can be increased through the addition of lime and subsequent deeper ripping below the plough depth.

In Australia, most soil inversion tillage is being practiced judiciously on sandy-textured soils - in particular deep sands, sandy earths, deep sandy duplex (texture contrast) and sandy gravel soils - to improve productivity.

Soil inversion tillage completely modifies the surface profile and is designed to bury all surface residues, leaving these soils vulnerable to wind erosion until a cover crop is established.

While this risk can never be eliminated, it can be minimised by ploughing the soil when wet and sowing a cover crop as soon as possible into the moist soil brought to the surface.

Inversion ploughing when the soil is wet is also essential, as sands lack cohesion when they are dry and the soil moisture helps the soil 'hold-and-fold' on the plough board or disc, thereby achieving more effective inversion.

Some growers have developed light, shallow-sowing seeding equipment for ploughed soils so they can seed them without rolling, while others will roll the soil first followed by immediate seeding.

Mouldboard versus one-way ploughs

Discrete element method (DEM) simulation results undertaken in GRDC-invested research at the University of South Australia indicate that using a mouldboard plough provides better topsoil burial than a deep working modified one-way disc plough.

However, disc curvature, diameter, disc angles, soil conditions, plough set-up and operation can all affect inversion effectiveness of one-way ploughs.

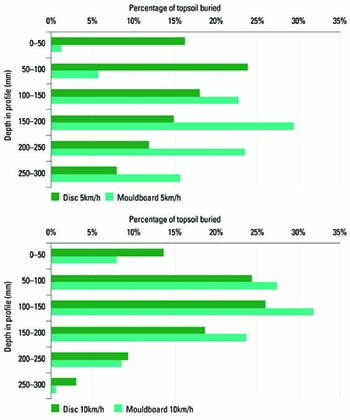

In the simulations undertaken, the mouldboard plough was more effective at burying topsoil below 200 millimetres than the one-way disc plough at a speed of five kilometres per hour.

The ability of the one-way disc plough to bury topsoil below 200mm is less affected by speeds up to 10km/h , but more topsoil is left at the surface than the mouldboard plough at this speed (Figure 1).

Figure 1 DEM simulation comparison of percentage of topsoil burial at each 50mm depth layer for disc and mouldboard ploughing at 300mm tillage depth. Source UniSA

Outcomes: Profitability

Profitability gains from using soil inversion in Western Australia, coupled with effective pH and compaction management, have highlighted the benefit of the practice.

Growers who have adopted the practices, using either mouldboard or one-way disc ploughs, have achieved high crop water-use efficiency and grain yield returns.

For example, research data over 10 years in WA indicates that, on average, cereal yield increases from inversion ploughing range from 500 to 900 kilograms per hectare in the first two years after tillage, depending on soil type, and that over subsequent seasons yield increases are maintained at 500 to 700kg/ha.

Outcomes: Yield increases and weed control

Plough choice also affects yield and weed control.

The addition of lime on acid soils and deep ripping below the plough depth in subsequent seasons can provide further yield increases.

Deep ripping below the ploughing depth can, on average, provide an additional 300kg/ha yield increase in cereals.

Soil inversion can also effectively bury weed seeds.

Effective inversion with a well-set-up mouldboard plough can reduce weed populations by more than 90 per cent.

Longer-term weed control from inversion has been shown to be enhanced by liming, which can improve crop vigour and competition and may influence the activity of some herbicides.

However, in most circumstances, modified one-way ploughs do not invert the soil as completely as mouldboard ploughs (see Figure 1), so effective weed control strategies after treatment are vital.

Soil inversion is a strategic method of constraint management and, when coupled with ongoing management of multiple soil and biotic constraints, has resulted in long-term benefits.

This is illustrated by some research experiments and grower demonstration trials that have showed continued productivity benefits for eight or more years after a one-off treatment.

More information:Dr Stephen Davies, DPIRD, 08 9956 8515, stephen.davies@dpird.wa.gov.au; Dr Chris Saunders, 08 8302 3664, chris.saunders@unisa.edu.au