While silica-based products such as diatomaceous earth have long been known to have insecticidal properties, recent research into the efficacy and mode of action of a synthetic form – synthetic amorphous silica (SAS) – has added to the understanding of its effectiveness as an insect control agent. SAS is set to have broad application in grain held in storages on-farm, at up-country facilities and in processing facilities. It is a food-grade product already in use, being non-toxic to humans, other mammals, birds, fish, plants and the environment generally.

SAS grain application

The potential use of SAS along the grains value chain stands to address two major issues: First, as on-farm grain storage infrastructure continues to increase, so does the challenge of insect resistance to grain protectants and the fumigant phosphine. This weakening of control methods is exacerbated by the use of older, difficult-to-seal storages and temporary facilities, not as suitable for fumigation. SAS could be used in these circumstances.

Secondly, grain customers are keen to further understand the role of SAS as an insect control agent, with grain millers and barley maltsters particularly interested in a silica-based product other than diatomaceous earth. They are keen to explore the potentially lower application rates of SAS and the advantage this gives in grain handling and processing.

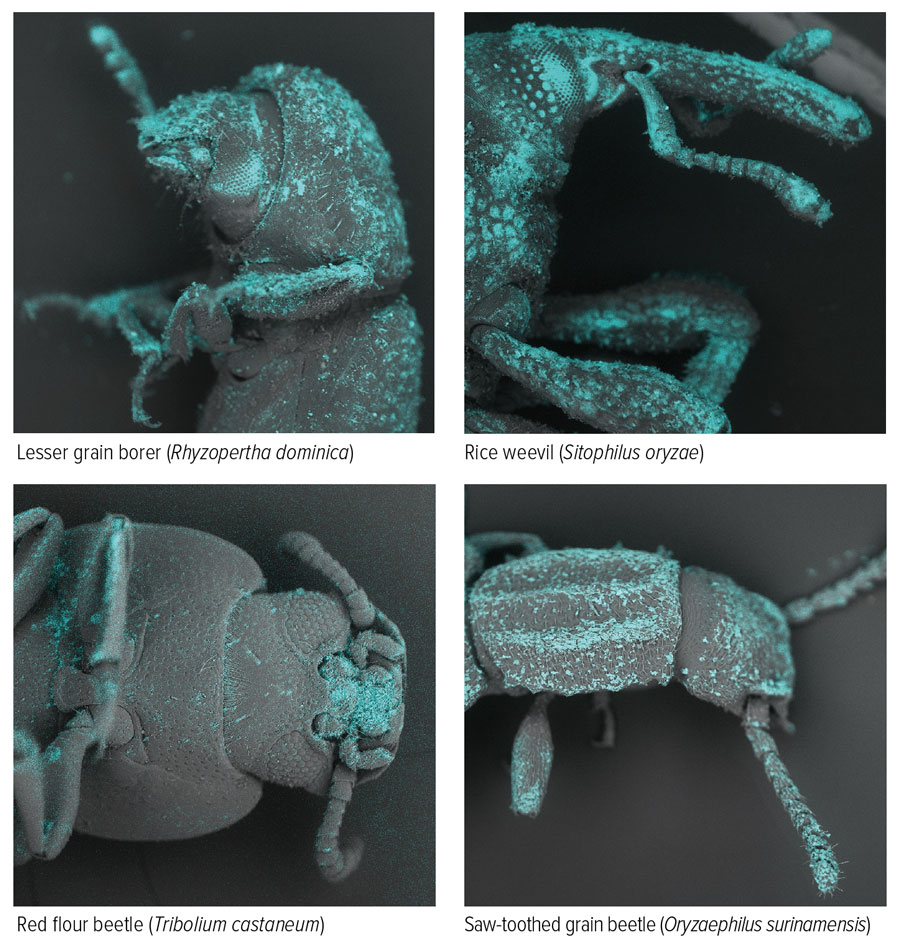

Figure 1: Overlaid images from Scanning Electron Microscope and Energy-Dispersive X-ray Spectroscopy of four grain storage pests; lesser grain borer, rice weevil, red flour beetle and saw-toothed grain beetle showing the successful transfer of synthetic amorphous silica from the grain commodity to the pests. The fluorescent colour indicates the presence of silica, rather than other elements or dust particles, at a coverage amount linked to mortality. Magnification x60.

Source: Davren Global

Innovative research

Initial research on SAS was funded through the Plant Biosecurity CRC and is owned by the Australian Plant Biosecurity Science Foundation. IP protection mechanisms are in place and Davren Global has a mandate to commercialise the technology. Further work on variables such as field environment, commodity type, insect species and SAS physio-chemistry is being done.

Using conventional, up-country, grain storage and handling equipment, these commercial specifications and optimal formulations are being resolved. Plus, electron microscopy tools have been used to learn the mode of action for SAS.

A library comprising more than 2000 diagnostic images has been compiled and annotated using Scanning Electron Microscope (SEM) and matching Energy-Dispersive X-ray Spectroscopy (EDS). These confirm the presence of silica as SAS on target insect species after contact with SAS-treated grain.

Industry specifications

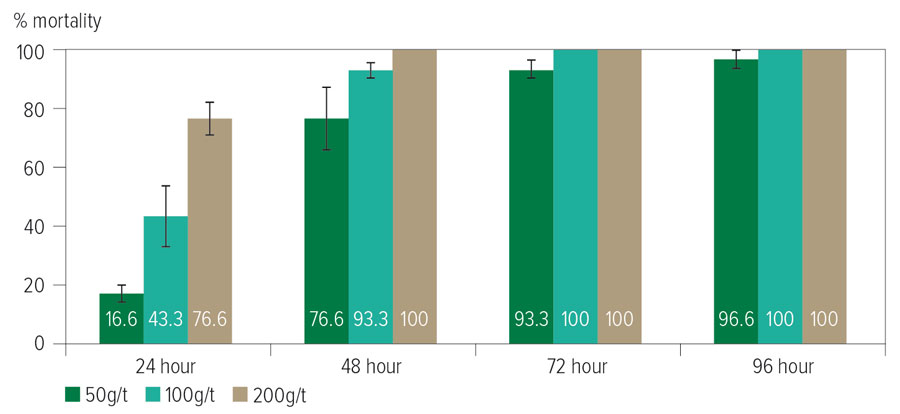

A key objective of the research is to achieve effective SAS kill rates at low application levels; ideally less than 100 grams per tonne for most grains, to avoid problems during grain handling and milling (Figure 2). Application rates greater than 100 grams per tonne can affect the bulk density and therefore handling properties of grain. Challenges such as these have plagued naturally occurring amorphous silica products such as diatomaceous earth.

Figure 2: Red flour beetle (Tribolium castaneum) knockdown rate (per cent mortality) trial in sorghum at 50, 100 and 200 grams SAS/tonne.

Source: Davren Global

Partnerships

In Australia, Davren Global’s work is supported with investment from GRDC and Sunrice. The Australian Centre for International Agricultural Research is also funding Davren Global’s collaboration with the Tropical Pesticides Research Institute in Tanzania, with a focus on corn. This recognises the potential application for SAS in subsistence farming operations, which suffer grain losses of up to 70 per cent due to pest infestations.

These R&D investors are providing the initial financial support to kick-start product development.

Davren Global is building additional partner relationships to leverage industry demand to further develop the core SAS products, technologies and solutions from the lab to commercial reality in three to five years.

More information: Tony Eyres, Davren Global, 0429 069 072, tony.eyres@davrenus.com