A new blend of sophisticated sensor technologies is set to provide a step change in the way growers approach harvesting, storage and marketing based on grain quality.

This is the focus of research led by Agriculture Victoria senior research scientist Dr Cassandra Walker as part of the Victorian Grains Innovation Partnership (VGIP), with co-investment from GRDC and Agriculture Victoria.

“We’re developing on-farm systems for accurately measuring grain quality that are accessible and affordable for growers,” Dr Walker says. The high-tech systems add a new precision dimension to grain quality assessment that aims to lift farm business profitability.

To this end, the systems’ sensor technologies enable growers to determine both the market class and quality grade of pulses and cereals defined by Grain Trade Australia (GTA) standards.

The ability to objectively classify grain quality is geared to help growers maximise the profitability of farm management decisions on whether to segregate, store or market grain.

The systems are also geared to measure variable grain quality across a standing crop, meaning they can be used on a paddock scale to prioritise harvest operations targeting areas containing high-quality grain. This new capability is currently being assessed by the Agriculture Victoria research team.

Such advances have the potential to “revolutionise” grower crop management practices, Dr Walker says. “We have proven the systems can segregate grain based on quality defects resulting from frost, heat, disease and, potentially, contaminants such as snails,” Dr Walker says.

One proof-of-concept system is now being applied to a suite of crops, including lentils, faba beans, chickpeas, wheat and barley.

Sensory fusion

Researchers examined the effects of imposed frost on desi chickpeas using sieves to determine the seed size distribution in grain samples. Photo: Cassandra Walker

In contrast with the new systems, commercially available on-farm devices are currently limited to measurement of grain protein and moisture using one type of sensor technology, near-infrared (NIR) spectroscopy.

Visual assessment is used to measure the remaining range of grain quality characteristics that determine commodity prices, particularly in high-value pulse markets around the world.

“Using visual cues outlined in GTA standards to assess grain quality is extremely labour-intensive, particularly for grain samples that have a high proportion of defects,” Dr Walker says.

Visual appraisal, for instance, defines the marketable quality of cereals and pulses based on the proportion of grain that is pinched and small (screenings), broken, split, stained or shrivelled in a bulk sample.

But superseding this traditional, subjective approach to quality assessment, the systems being developed by Agriculture Victoria researchers combine NIR spectroscopy with another sensor technology – red-green-blue (RGB) imaging.

NIR spectroscopy uses near-infrared radiation to analyse the composition and characteristics of grain samples in specific wavelengths of the electromagnetic spectrum, whereas RGB imaging uses red, green and blue filters with pixel sensors to capture grain colour and surface information.

“Many growers have already installed NIR spectroscopy devices on their headers. These devices can monitor grain protein and moisture while a crop is being harvested,” Dr Walker says.

“The systems we are developing also apply this technology, but they take quality assessment a step further by combining NIR spectroscopy with RGB imaging.” Plus, the research has expanded the scope of the quality attributes that NIR technology can detect.

High-tech assessment

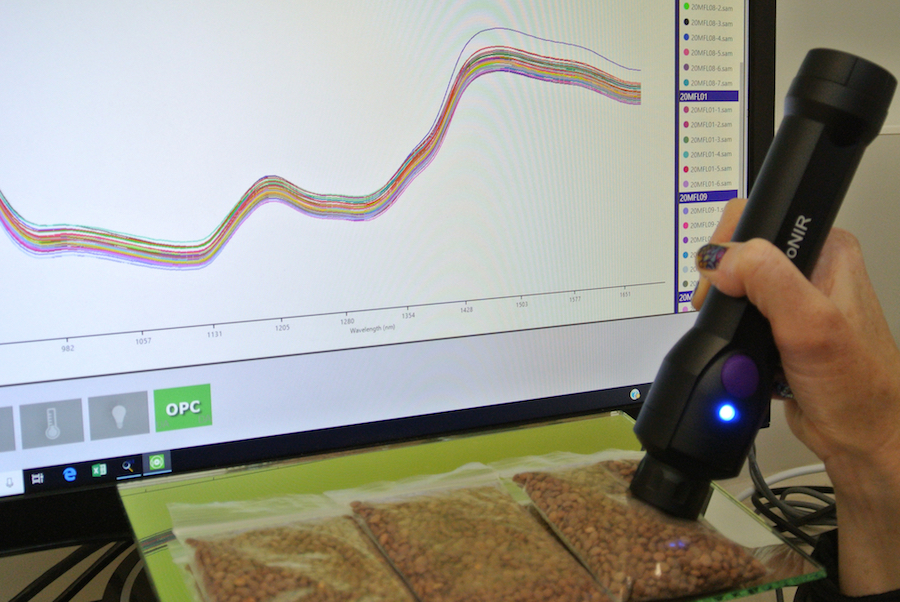

Dr Walker scans reference lentil samples with a MicroNIR™ instrument to collect NIR spectra data (shown on computer screen) for algorithm development. Photo: Cassandra Walker

Chasing these high-tech objectives, scientists applied machine learning techniques to develop a series of algorithms that, in effect, adapt the functionality of both sensors to grain quality detection.

For example, the research team demonstrated that NIR spectroscopy could not only accurately estimate grain protein and moisture, but also the percentage of contaminated grain in a bulk sample.

Complementing this, RGB imaging can also measure the percentage of grain defects in bulk samples with high accuracy. But, more importantly, it has aptitude for assessing aesthetic traits such as grain size and colour. The ability to detect grain size can be used to assess screenings, while the ability to detect colour linked to grain defects, such as staining, can be used to sort defective and sound quality grain, Dr Walker says.

To date, scientists have road-tested the efficacy of NIR spectroscopy installed on a harvesting machine and auger to assess pulse quality for the past three seasons, from 2019-20 to 2021-22. The research team also plans to put RGB imaging sensors to the test in cropping paddocks this year.

The research indicates that combining NIR and RGB sensors, with a new sampling and software system for integrating algorithms, on the auger-based system could potentially capture data every second.

Dr Walker says development of NIR spectroscopy was informed by three years of data collected from pulse cropping paddocks on eight Victorian farms.

The paddock data includes the findings of a study examining the effects of natural and imposed frost and heat-stress episodes on different varieties of lentils and faba beans. “The team found that grain size and yield were the most spatially variable quality traits across paddocks,” Dr Walker says. “And these variable quality traits were influenced by the intensity and duration of frost and heat-stress events, as well as different soil types.”

Together, these findings suggest sensor estimates of grain size and yield can be used to gauge spatial variation in grain quality which, in turn, can be used to guide harvest operations on an intra-paddock scale.

The functionality of both the header and auger-based set-ups will be demonstrated as part of a grower workshop following harvest this year. Grower input gleaned from the workshop is expected to shape ongoing development of the sensor technologies, Dr Walker says.

For instance, she says there is potential for growers to access the system via an app or smartphone camera. The research team also aims to explore the option of combining a third sensor technology – multispectral imaging – with NIR and RGB sensors.

More information: Cassandra Walker, cassandra.walker@agriculture.vic.gov.au