Key points

- Newer, high-yielding varieties are proving to be difficult to desiccate with current chemical options

- An alternative option, swathing or mechanical desiccation, may be equally or more effective

Mechanical desiccation – or swathing – has potential to provide a more effective alternative to chemical desiccation.

Recent improvements in mungbean varieties have resulted in higher-yielding, more-vigorous plants that are more difficult to desiccate effectively. Chemical desiccation prior to harvest aids in plant dry down to facilitate harvest and maximise grain quality.

Moisture remaining in the stem is problematic for harvest and causes seed coat staining resulting in downgrading of grain quality. Mungbean growers have been searching for more-effective desiccation methods.

There are four herbicides registered for mungbean desiccation in Australia – glyphosate and diquat, along with metsulfuron-methyl and saflufenacil when mixed with glyphosate or diquat; glyphosate is the most-used product. Current industry best practice is to apply registered chemical desiccants once the crop has reached physiological maturity and 90 per cent of pods have changed colour to brown/black.

Anecdotal evidence has suggested that mechanical desiccation of mungbeans – also known as swathing or windrowing – could be used for drying down the crop in place of chemical desiccation.

Some key markets have reduced or removed their import tolerances to glyphosate residues in mungbean.

The use of swathing would enable Australian mungbean to access these high-value markets once again. Illegal use of higher-than-label rates or unregistered chemicals put all markets at risk.

Swathing

Swathing was trialled by several growers in 2020-21, despite the limited published research in mungbeans.

To find out if swathing is effective, the Queensland Department of Agriculture and Fisheries and NSW Department of Primary Industries implemented small plot replicated trials in 2021 at Emerald and Warwick in Queensland and Narrabri in NSW.

The trials, undertaken as part of a GRDC investment in mungbean agronomy, were designed to compare the ideal timing of chemical and mechanical desiccation to maximise mungbean yield and grain quality.

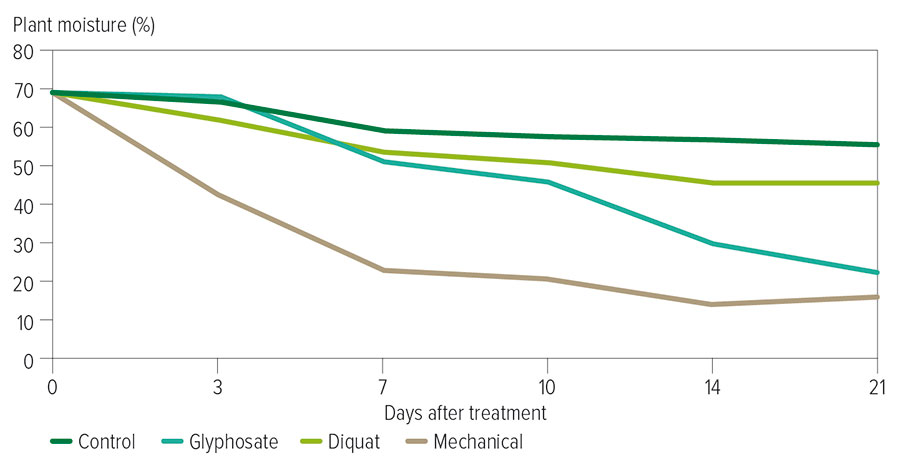

Treatments compared mechanical and chemical desiccation at 30, 60 or 90 per cent crop physiological maturity. Plants were sampled at zero, 3, 7, 10, 14 and 21 days after treatment (DAT) to determine plant moisture (to track dry down), grain yield and grain quality.

The ideal stage for desiccation (chemical or mechanical) was when a majority of the crop had reached physiological maturity. This can be difficult to assess in the paddock and is typically judged as being when 90 per cent of pods have changed to a brown/black colour. However, pod colour is not a reliable method.

To assess maturity more accurately – which can be from pod yellowing onwards – split the pods longitudinally. Mature seeds will fall away from the inside pod coating.

Early indicators

The results showed that mechanical desiccation allowed faster dry down and earlier harvest. Mechanical desiccation was best performed when the crop was at physiological maturity, with 90 per cent of pods having changed colour to brown/black. Earlier desiccation reduced grain quality and yield by up to 500 kilograms per hectare in some cases.

Figure 1: Mungbean moisture content at Emerald, Queensland, after chemical and mechanical desiccation at crop physiological maturity (LSD = 3.42, p=0.05).

Source: Jayne Gentry

Grain quality was more consistent with mechanical desiccation. However, yield can decline if mechanically desiccated mungbeans are not picked up in a timely manner. Grain is also more vulnerable to damage by mice and rain after swathing.

While the results from this small plot research indicate that mechanical desiccation may be an effective alternative to chemical desiccation, the technique needs to be tested in the paddock with commercial scale equipment.

The mungbean agronomy project team are rolling out paddock strips in collaboration with mungbean growers in the 2022 season to add further insights into mechanical desiccation of mungbeans.

More information: Jayne Gentry, 0428 459 138, jayne.gentry@daf.qld.gov.au