An innovative form of computer modelling known as discrete element method (DEM) is providing an opportunity to simulate machine setting scenarios to develop a performance index for soil amelioration equipment.

A range of tillage equipment is used to ameliorate problematic soils, including mouldboard ploughs, two-way disc ploughs and rotary spaders. Their efficacy in mixing soils is tested in field trials but optimising performance can be expensive and limited in terms of the number of scenarios that can be assessed.

Dr Mustafa Ucgul brings extensive training to this evaluation task. He holds a bachelor’s degree in science in mechanical engineering and a master’s in science in agricultural machinery from universities in Turkey, a master’s in mechanical engineering from the University of South Australia, together with a PhD in soil-tool interactions using DEM.

He is completing a GRDC-supported research fellowship investigating the operation of rotary spaders using DEM to see how mixing uniformity is controlled and affects crop responses to different amendments.

He is teaming with Dr Jack Desbiolles and Dr Chris Saunders at the Agricultural Machinery Research and Design Centre at the University of South Australia. Their work also benefits from a close collaboration with Dr Lynne Macdonald (CSIRO) and Trengove Consulting (Bute, SA).

“DEM is a cutting-edge technology that can be used to model the operations of most agricultural machines. In our case, this significantly helped us fully understand the processes involved in how a tillage machine affects the soil profile and how we can improve its performance to address specific soil constraints,” Dr Ucgul says.

His research is twofold: examining whether crop yield responses can be improved by optimising the mixing of lime in acidic soils, and the incorporation of animal manure in soils with poor organic matter content.

Field trials over two years investigated both components and were then complemented with DEM simulations.

Lime example

The lime trial on an acidic site contrasted the effect various spading treatments, such as high mixing uniformity (that is, two passes at 2.4 kilometres per hour), medium mixing uniformity (one pass at 5km/h, commonly used by growers) and low mixing uniformity (one pass at 9km/h). Two years of results show that spreading up to 6.6 tonnes per hectare of lime on the surface – without mixing – did not achieve any significant impact on crop vigour or yield.

“However, spading in the lime treatments increased crop vigour by up to 52.7 per cent in year two, relative to the control,” Dr Ucgul says.

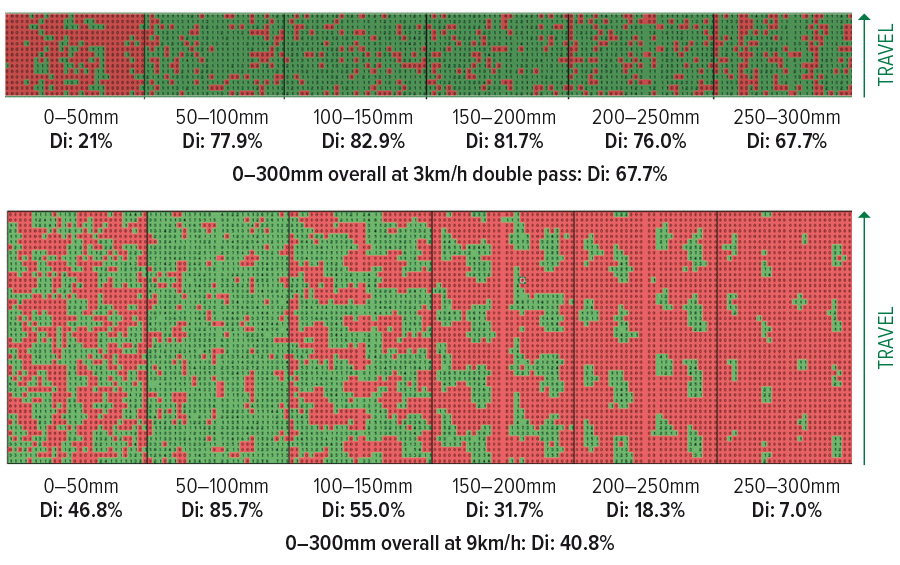

Figure 1: Computer simulation results representing the mixing uniformity and incorporation of lime within a spaded soil profile within 50mm soil layers. The area represents 4 blade widths x 4 bite lengths, seen from a top view. The Di value quantifies the green proportions of the soil volume. NB: Green indicates soil zones containing lime and red indicates soil zones without lime.

Source: University of South Australia/AMRDC.

In year one of the experiment, barley grain yield increased by 0.37t/ha or 8.7 per cent over the control when lime was incorporated by spading, but only in high uniformity mixing treatment. This benefit was also maintained in year two when lentil was grown, with 37 per cent greater biomass in the high uniformity treatment. Grain yield responses were not statistically significant, presumably due to harvest losses.

“The data to date indicates that lime should be incorporated through the profile and mixed thoroughly for the most rapid crop response.”

DEM simulations were run to quantify the extent and uniformity of amendment mixing under various soil and machine scenarios. A mixing index (Di) was developed to quantify the level of mixing. The objective is to provide an accurate basis for comparing treatments and correlate these with crop responses.

A series of simulation results show what happens when lime particles placed on the soil surface are mixed through at zero to 300-millimetre depths with 50mm resolution (Figure 1). The percentage of the spaded soil volume that contains some lime (Di value in Figure 1) ranged between less than 10 per cent at depth to greater than 80 per cent in shallow layers.

“My motivation is to improve existing tillage tools. This can significantly help the Australian grains industry and also assist agricultural machinery manufacturers,” Dr Ucgul says.

More information: Dr Mustafa Ucgul, 0433 463 916, mustafa.ucgul@unisa.edu.au