Key points

- Match tillage implement to soil type and constraint

- There are three broad categories of strategic tillage: ripping, mixing and inversion. Each has a different impact on the topsoil and soil amendments

Diagnosing the nature and extent of soil constraints present in a paddock is key to determining which strategic tillage method to apply.

Taking soil samples at depth for chemical analysis helps identify soil pH extremes, sodicity, toxicities and nutrient deficiencies in the profile.

Push probes or penetrometers used in wet profiles can indicate hardpan layers.

Water repellence can be assessed through observation and in-field or laboratory testing of water or alcohol infiltration.

For constraints confined to the topsoil and immediate subsurface layer, shallow tillage to mix the soil may be adequate. This could include shallow incorporation of lime into an acid topsoil or stubble and nutrient incorporation.

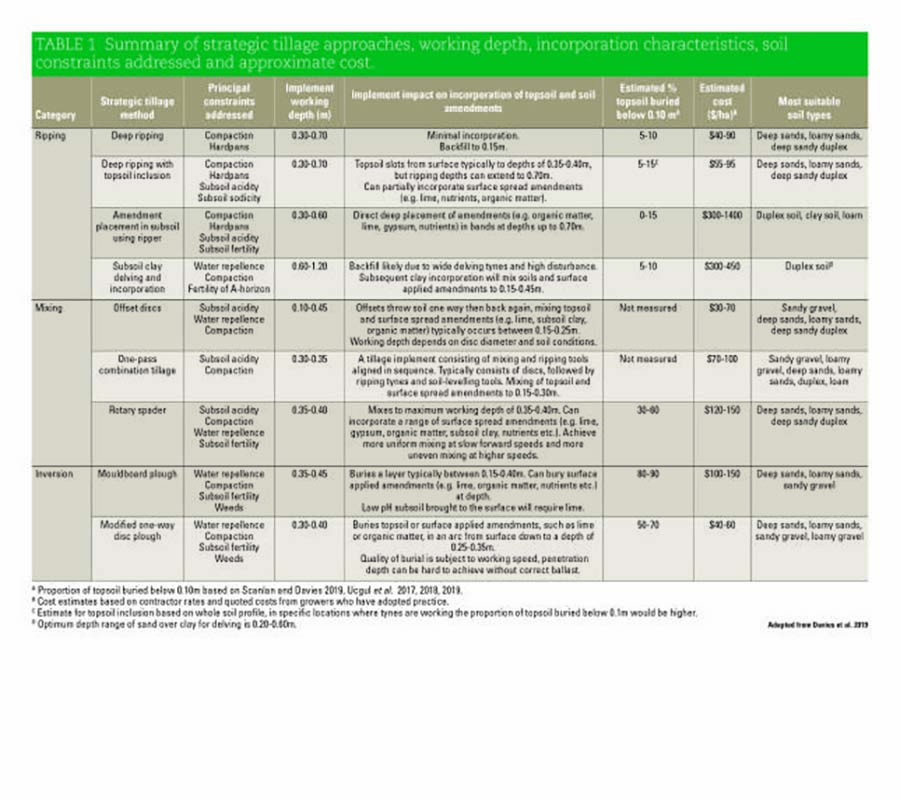

Strategic tillage may be useful as a one-off renovation tool every 10 years or more. It falls into three broad categories defined by the constraints that are being addressed and their physical impact on the soil profile. They vary in degree of topsoil burial, subsoil disturbance and lifting (delving) of subsoil to the surface (see Table 1).

These categories are:

- ripping - fracturing deeper subsoil using tyned rippers;

- mixing - soil mixing typically using passive offset discs, powered rotary implements or one-pass combination tillage systems; and

- inversion - soil inversion with mouldboard, one-way or square ploughs.

Strategic tillage methods

Deep ripping uses deep working tynes, often narrow, which in optimum soil conditions fracture and loosen subsoil hardpans with minimal topsoil mixing.

If the soil is too wet, fracturing is reduced and the ripper tyne can cause a narrow slot. If the soil is too dry, large clods can be brought to the surface.

Deep ripping variations include topsoil inclusion or direct deep placement of amendments behind ripping tynes and delving using large, broad, angled tynes to lift subsoil clay to the surface (see Table 1).

Mixing aims to incorporate topsoil and associated stratified nutrients and surface-applied soil amendments (for example, lime) deeper into the soil profile.

The degree and depth of mixing is determined by the implement type, its set-up and operation, and the soil texture and moisture conditions.

For passive offset discs and powered rotary spaders, penetration depth is improved with good subsoil moisture conditions and pre-ripping to loosen the subsoil hardpan.

Consider the physical impact your tillage implement will have on your soil.

- DPIRD researcher Dr Stephen Davies

Rotary spaders lift some subsoil seams to the surface while burying topsoil in pockets due to the fixed driven rotation of the spade rotor and effective bite length.

In texture-contrast soils, spaders can bring up and mix some clay subsoil from depths of up to 300 millimetres, but are poorly suited to soils containing rock or cemented gravel.

One-pass combination tillage implements combine a series of shallower working mixing discs with deeper working tynes and soil-levelling tools.

These typically mix the surface soil with some subsoil loosening, but cannot bury topsoil or amendments as well, or as deep, as spaders or large-diameter offset discs.

Soil inversion is appropriate when near-complete burial of the surface layer is needed due to weed seeds and/or water-repellent topsoil.

Mouldboard ploughs are most effective at inversion, provided the soil is moist and ploughs are set up correctly.

Modified one-way disc ploughs with large-diameter discs are a cheaper, slightly more robust alternative to the mouldboard plough. Depending on soil type, conditions and plough set-up, burial can be effective, although not as complete as a mouldboard plough.

The rolling action of the discs can be used in sandy gravel soils and they are better able to ride over rock than mouldboard ploughs.

Amendments incorporated through soil inversion tend to be buried in a layer rather than mixed to depth.

Considerations

A nine-furrow reversible Kverneland mouldboard plough. Photo: DPIRD

Soil type and variability will limit the use of some methods that risk bringing up too much shallow and/or toxic clay or rock.

Deep sands and shallow soils will still have limited water-holding capacity after amelioration, so the level of investment in strategic deep tillage needs to be carefully considered.

Growers should also be aware that crops often produce higher biomass after amelioration and these crops can be at greater risk of haying off, especially in lower-rainfall environments.

This risk can be managed through trying to control biomass production and early water use.

This includes using shorter-season varieties, reducing sowing rates, increasing row spacing, crop grazing or judicious application of nitrogen fertiliser to avoid rapid early growth.

More information: Dr Stephen Davies, DPIRD, 08 9956 8515, stephen.davies@dpird.wa.gov.au

References

Scanlan CA, Davies SL (2019) 'Soil mixing and redistribution by strategic deep tillage in a sandy soil.' Soil and Tillage Research 185, 139-145.

Ucgul M, Saunders C, Desbiolles JMA, Davies SL, Parker W (2019) 'Improving the effectiveness of soil amelioration by optimising soil machine interaction.' 2019 GRDC Grains Research Updates, 25-26 February 2019, Perth, Western Australia. Grains Industry Association of Western Australia 2019 research updates.

Ucgul M, Saunders C, Fielke JM (2017) 'Discrete element modelling of tillage forces and soil movement of a one-third scale mouldboard plough.' Biosystems Engineering 155, 44-54.

Ucgul M, Saunders C, Li P, Lee S-H, Desbiolles JMA (2018) 'Analysing the mixing performance of a rotary spader using digital image processing and discrete element modelling (DEM).' Computers and Electronics in Agriculture 151, 1-10.