Key points

- Field measurement of how various tillage implements relocate soil vertically, laterally and along the direction of travel can inform how effective the implement is at mixing or inverting the soil and suitability for soil amelioration

- Implements which create the highest level of mixing are better suited to incorporating an immobile soil amendment, such as lime

- Implements which do a more thorough job of deep inversion are better suited to burying water-repellent topsoil and weed seeds

Understanding how an implement interacts with the soil and changes the soil profile is critical to selecting the appropriate tillage implement - not only to overcome soil constraints, but also to influence the availability of soil nutrients and the effectiveness of soil amendments.

Implement selection involves studying the movement of the soil in three dimensions - vertically, laterally, and along the direction of travel after the tillage implement has passed.

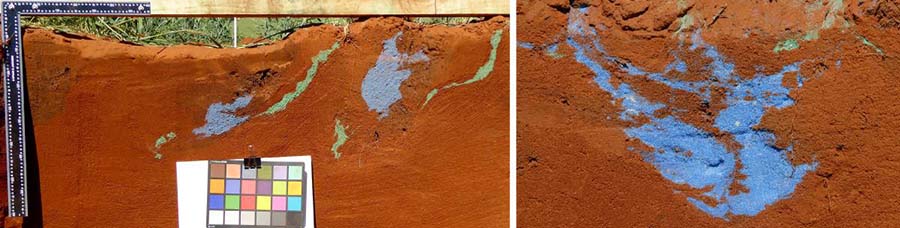

Soil profile images showing redistribution of blue sand buried at zero to 10cm and green sand at 20 to 30cm as a result of tillage by a mouldboard plough (left) and a spade on a rotary spader (right) over the same soil depth. Photo: DPIRD

In this respect, field-based investigations by scientists from the Western Australian Department of Primary Industries and Regional Development (DPIRD) and the University of South Australia have used coloured sand as a visible tracer for the movement of soil by tillage. The coloured tracers had similar density and flow characteristics as the bulk soil.

Coloured tracers were buried in trenches at specific depths in locations along the path of the tillage implements and the soil repacked around them.

After the tillage implements passed, pits were dug and digital imagery of the shift in coloured soil captured.

Figure 1, left image, shows how a mouldboard plough can distribute sand placed at two different depths throughout the profile, while Figure 1, right image, shows how a spade from a rotary spader can mix sand through a profile.

By taking multiple images of the layers, either two-dimensional or three-dimensional views can be created of soil from various depths, and the depth and lateral movement of soil quantified.

This can provide detailed insights into the extent to which topsoil and surface-applied amendments are buried and mixed to depth.

A comparison of soil movement by a mouldboard plough, rotary spader and one-way disc plough showed some similarities.

All these implements created a patchy soil profile, where soil from the different layers was not well mixed, but were instead layered or rotated by tillage.

The offset discs caused the greatest fragmentation of the topsoil - it was broken up into smaller pieces compared with the other tillage implements. The distance between patches also differed.

Topsoil patches buried by the mouldboard plough were about 55 centimetres apart and for the rotary spader about 35cm apart. The distance between patches of buried topsoil depended on the distance between cutting edges on the implements.

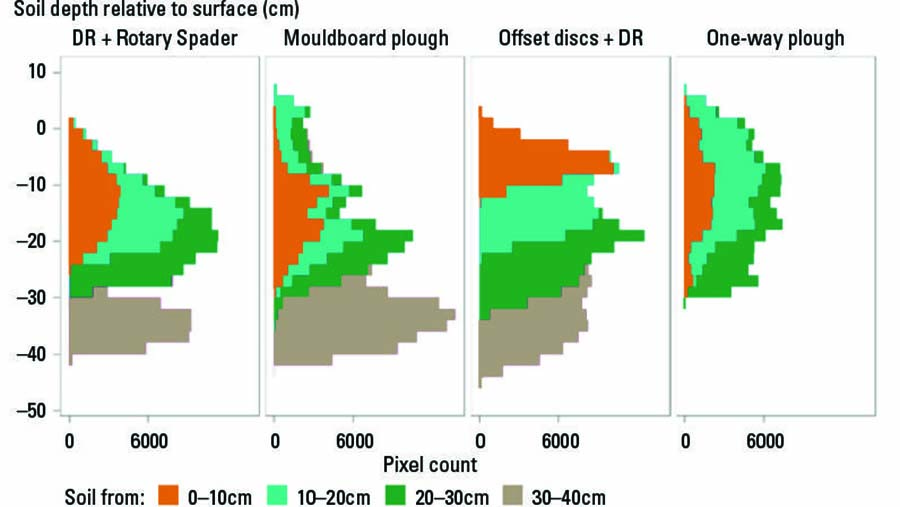

Figure 2: Two-dimensional graphic showing how soil originating from different 10cm depth increments is proportionally redistributed vertically through the soil profile by different tillage implements. Pixel count is a measure of the number of coloured tracer pixels in a depth layer. Loosening of the soil can result in some soil being relocated above the original soil surface. DR is deep ripping. Source: DPIRD

Figure 2 shows vertical redistribution of soil layers by a deep ripper (DR), in combination with either a rotary spader or offset discs, and a mouldboard or one-way plough.

An implement that does a more thorough job of mixing the soil to depth will be better suited to incorporating an immobile amendment, such as lime, into acid subsoils.

An implement that does an effective job of completely burying the surface soil will have advantages for managing weed seeds and overcoming topsoil water repellence.

Mouldboard ploughs and one-way ploughs are effective at this (see Figure 2).

About 80 per cent of soil from zero to 10cm was buried by the mouldboard plough, about 60 per cent by the one-way disc plough and rotary spader, and about 10 per cent by the offset discs (see Figure 2).

These in-field assessments and understanding of soil movement are being used to validate computer simulation models by the University of South Australia.

Once calibrated, these models are a cost-effective means to further understand the impact of factors such as implement design and set-up, depth and speed of working and soil characteristics, which can influence soil movement and the outcome achieved.

More information: Dr Craig Scanlan, DPIRD, 08 9690 2174, craig.scanlan@dpird.wa.gov.au