Snapshot

Growers: Peter, Pat and Robert Allen

Location: Grogan, New South Wales

Total farm area: 2995 hectares

Area cropped: 2105ha

Average annual rainfall: 525 millimetres; 2020 (January to November): 521mm

Soil types: grey clay; red soil

Topography: Flat

Soil pH: 5.0 to 6.5 (topsoil); 8.5 to 9.5 (subsoil)

Enterprises: grain and sheep

Crops grown: wheat, canola, barley

Cropping sequence: wheat/canola/wheat/vetch and barley/wheat/barley/lucerne and clover.

After a year with flooding, another year with a dry spring and two years of drought, conditions in 2020 marked a turnaround that will put much-needed income back into Peter and Robert Allen’s business at Grogan, New South Wales.

For Peter and his son Robert, who run a mixed-farming operation 128 kilometres north-east of Wagga Wagga, the seasonal turnaround in 2020 has lifted spirits. But it did not come without worry.

While rainfall during 2020 was above average for much of the growing season, conditions turned dry in early October, prompting concern about whether their hostile soils would allow crops to access subsoil moisture and fill with grain.

“We certainly had substantial crops with large amounts of biomass,” Peter says. “But we worried that if it didn’t continue to rain, the crops would fail to fill because of our sodic soils.”

Difficult-to-manage sodic subsoils pose numerous problems and make growing grain a challenge – one that Peter has been working to overcome for almost 40 years.

Sodic soils

Sodic subsoils disperse or lose their structure when they become wet. When the soil disperses, clay particles tend to clog pores in the soil, making the soil hard. This reduces rainfall infiltration, increases moisture runoff and causes transient waterlogging.

As the soil dries, a hard crust often forms, either on the surface or in the subsoils, which inhibits crop emergence and root proliferation through the subsoil. Accordingly, crop access to water and nutrients in dry springs is constrained, which reduces grain fill and constrains yields.

Peter and Robert’s landholding straddles the upper reaches of the Bland Creek. About 80 per cent of their farm has a sodic soil subsoil, with some sodicity also affecting the topsoil.

“Generally clays are the best soils you can get, but not the sodic ones,” Peter says. “These have many issues that limit our grain production.”

Forty centimetres beneath the soil surface, tests show pH is about 9.0 which can lead to chemical toxicities. By contrast, the topsoil pH ranges from 5.0 to 6.5.

Wheat dominates

Wheat is the focus at Peter and Robert’s farm, comprising about 40 per cent of their grain production, because it has proven more tolerant than other crops to sodic soils.

Lucerne is grown because its extensive root system can crack open the hard, sodic subsoils to allow water to infiltrate and add much-needed organic matter to the soil. “You don’t have to change the organic matter much to see an improvement in soil structure,” Peter says.

Lucerne dries out and cracks open the hard, sodic soils on the Allens’ farm, allowing rainfall to penetrate to depth. The extensive root system also adds organic matter into the subsoils. Photo: Nicole Baxter

Gypsum was first applied to sodic soils on the farm during 1978 and made a big difference to water infiltration and crop establishment. Low-level drains were also put in and land was graded to move water off paddocks.

Another major turning point was the introduction of balansa clover into the family’s farming system. “It was a breakthrough species for us because it tolerates waterlogged soils and produces enormous amounts of biomass, which improved soil organic matter and soil structure,” Peter says.

“In the early days, surface application of gypsum, followed by growing balansa clover, led to large increases in yield, largely due to improved crop establishment, crop growth and increased tillering.”

Subsoil challenge

While these changes saw improvements in Peter and Robert’s topsoils, the subsoils remained hard in dry conditions and waterlogged in wet conditions. They continued to look for ways to improve their crops’ access to water stored at depth, especially as dry seasons became more frequent.

Through the Australian Grain Leaders Program, Robert researched ways to improve the health of the soils on the family farm. During his research, Local Land Services officer Geoff Minchin told him about the work of NSW Department of Primary Industries senior research scientist Dr Ehsan Tavakkoli, who had received GRDC investment to look at ways of improving sodic and dispersive subsoils.

Shortly thereafter, Peter and Robert saw Dr Tavakkoli talk at a GRDC Update about research results at Rand, which showed deep-placed pea hay, gypsum and added nutrients lifted barley yields by 27 per cent.

After hearing these results, Peter and Robert met Dr Tavakkoli and spoke about their difficult soils. At the time, Dr Tavakkoli was looking for a new trial site for his research, so the trio decided to collaborate.

However, drought in 2018 and 2019 resulted in little yield response to deep-placed ameliorants in trial work on their farm, especially as deep ripping also tends to dry out the soil.

Nonetheless, in 2020, the third season after the treatments were imposed, Dr Tavakkoli says preliminary biomass cuts have shown deep placement of organic amendments plus gypsum and nutrients has improved wheat growth by about 30 per cent compared to surface-applied treatments or the untreated control. Grain yield results are yet to be analysed.

Peter says the results, coupled with the turnaround in seasonal conditions, have provided a much-needed lift in enthusiasm.

“There are big benefits if we can ameliorate our subsoils, but deep application of organic amendments such as lucerne and pea is expensive because at the moment they need to be made into pellets,” he says.

“Once we can sort out the technology to place organic ameliorants into the subsoil in an efficient way, we might be able to see the significant yield improvements that Ehsan’s research has shown.”

Pot experiments

One ameliorant included in Dr Tavakkoli’s research is called polyacrylamide (PAM). The substance is a polymer that reduces soil dispersion. It is sometimes used in horticulture.

Dr Tavakkoli and his team at the Wagga Wagga Agricultural Institute have run pot trials looking at the impact of PAM on root proliferation through sodic soils from Grogan.

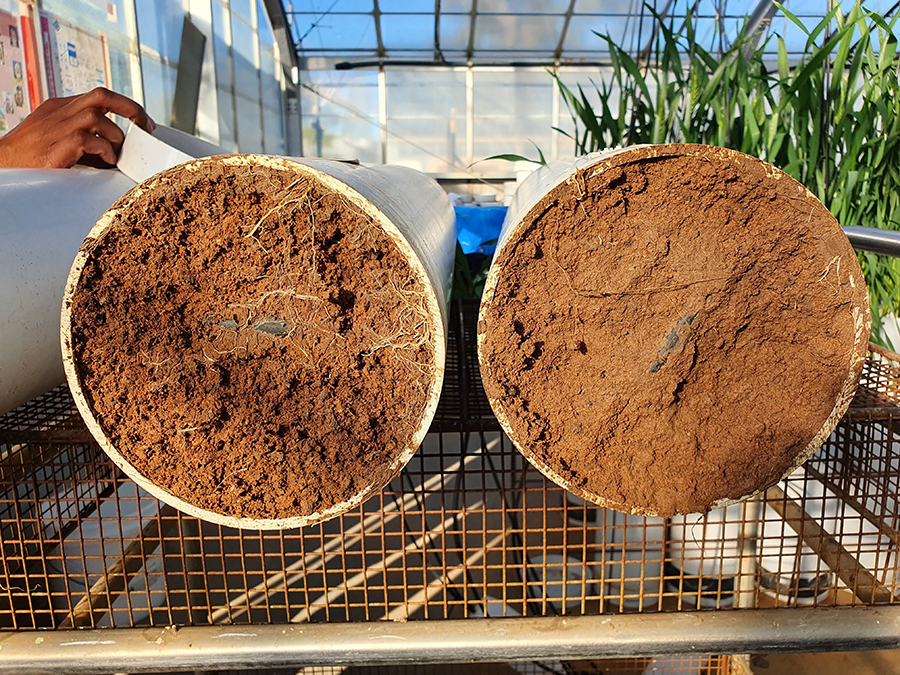

Preliminary observations show improved root proliferation through sodic soils when PAM is mixed with an organic amendment compared to the control.

Pictured left is root growth in 50-centimetre soil tubes where polyacrylamide plus an organic amendment was applied. Pictured right is the control treatment. Photo: Dr Ehsan Tavakkoli

Dr Tavakkoli is also developing new organic-based fertiliser, gypsum and lime products. These comprise sub-micron-sized particles of fertiliser, lime or gypsum applied to organic matter which acts as a carrier for subsoil applications.

Preliminary observations of these novel amendments demonstrated a significant improvement in root proliferation through the soil and crop water use in soil columns when treated with sub-micron-sized amendments. Further trials are necessary to test the amendments in the field.

Research essential

While variable seasonal conditions remain a constant challenge, Peter and Robert remain quietly confident that research will find ways to adapt and remain viable.

“Having a suite of technologies available to us is important,” Peter says. “Hopefully, in the not-too-distant future we can unlock cost-effective ways to ameliorate our sodic subsoils, so our crops can tap into moisture stored at depth in dry seasonal conditions.”

More information: Peter Allen, 0427 739 462, allenp10@bigpond.com; Ehsan Tavakkoli, 0421 018 075, ehsan.tavakkoli@dpi.nsw.gov.au