Key points

- The 3D ripping machine can be used to treat multiple soil constraints, such as soil acidity, sodicity and compaction.

- Deep ripping with lime and/or organic amendments may speed up the amelioration of subsoil acidity.

Deep ripping with lime and/or organic amendments is being investigated to see whether it can speed up the amelioration process in areas where crop production is constrained by subsoil acidity.

Subsoil acidity is a major constraint to crop productivity in the high-rainfall zone (500 to 800 millimetres per year) of south-eastern Australia. However, lime movement from surface liming is very slow - about 10mm per year.

Unlike sandy soils in Western Australia, the soils in south-eastern Australia often have subsoil acidity problems due to higher clay contents associated with high bulk density (1.5 to 1.7 grams per cubic centimetre) and high pH buffering capacity.

As a result of this, specialised equipment and large numbers of amendments are required to cost-effectively ameliorate these difficult soils, which occur across the high-rainfall zone of southern New South Wales and north-western Victoria.

Through GRDC-invested research at the NSW Department of Primary Industries, we have designed and fabricated a prototype ripping machine to deliver lime, gypsum and/or organic amendments as well as liquid fertiliser, if required, at two depths.

Coined the 3D (dual depth delivery) ripping machine, it has undergone rigorous testing and further modifications over the past few years and is now proving to have an impact on multiple soil constraints, particularly soil acidity, sodicity and compaction.

Key features

The 3D ripping machine features:

- dual amendment boxes to hold lime and organic amendments separately. It can also deliver liquid fertiliser;

- dual augers to deliver lime (up to four tonnes per hectare) and organic amendment (up to 20t/ha) simultaneously;

- dual exit points and plates on each tyne to provide flexible delivery of both lime and organic amendment at different depths;

- dual fluted roller metering systems with variable gearboxes to ensure accurate application rates as required;

- front coulter to break topsoil and prevent surface layer being lifted; and

- back roller to compress soil behind the ripper and leave a flat surface ready for sowing.

The 3D ripping machine was tested at the 'Ferndale' property at Dirnaseer, west of Cootamundra in NSW, on a red chromosol with severe soil acidity problem at depths.

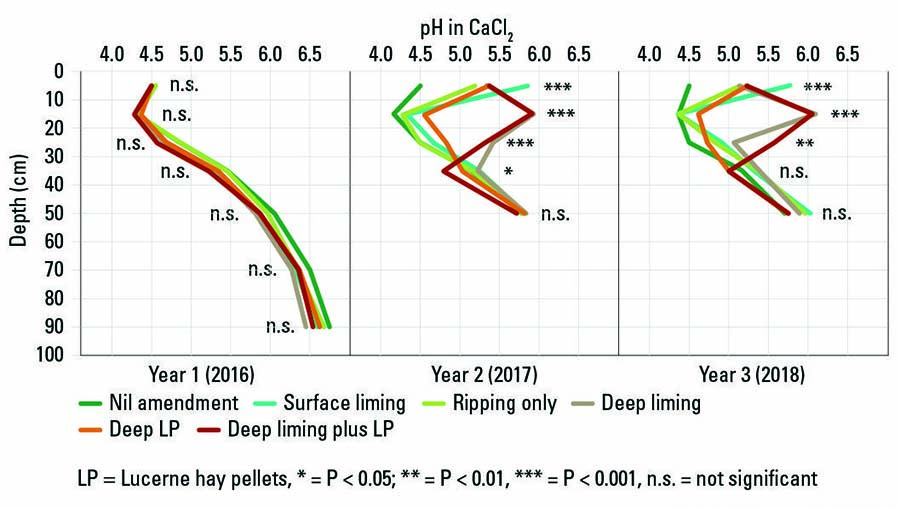

Figure 1 Soil pH in CaCl2 under different soil amendment treatments in years 1 to 3 at the Cootamundra, NSW site.

Source: Dr Guangdi Li, NSW DPI

Soil pH

Soil pH changes were monitored before and after deep ripping with lime and organic amendment.

Figure 1 (middle graph) shows that surface liming increased pH to 5.9 at zero to 10cm, as designed.

The deep-limed treatment with and without organic amendment (lucerne hay pellets) significantly increased soil pH at 10 to 20cm, and 20 to 30cm, as expected. Similar trends were found from results in 2018 (year three).

Soil strength

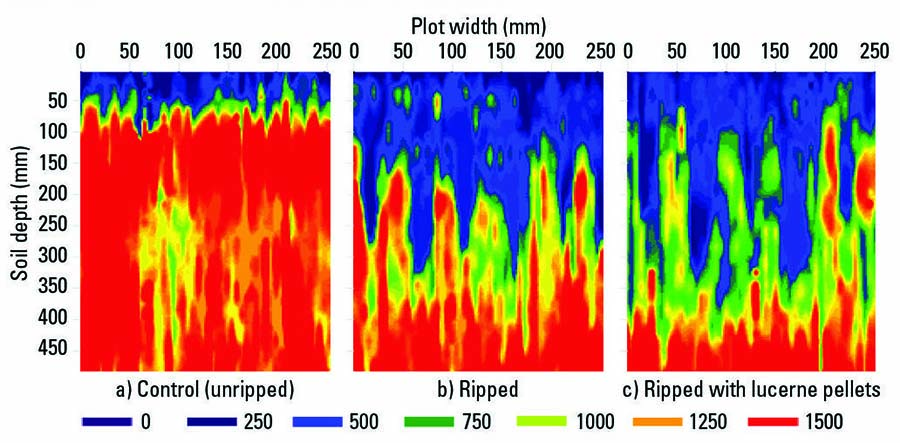

Figure 2 Penetrometer readings (kilopascals) on plots under a) control, b) ripped and c) ripped with lucerne hay pellet treatments.

Source: Dr Sergio Moroni, Charles Sturt University

Penetrometer readings for the unripped, ripped and ripped with lucerne pellet treatments are shown in Figure 2 and demonstrate the effectiveness of the 3D ripping machine in changing soil strength five months after treatment. The ripping space is 50cm with five tynes.

It is expected that the combination of lime and organic amendment application could facilitate lime movement down the soil profile over time and the deep-ripping action could improve root penetration.

The long-term effects of deep ripping on soil chemical, physical and biological properties will continue to be monitored during the project's life.

More information: Guangdi Li, 0407 906 387, guangdi.li@dpi.nsw.gov.au, Managing subsoil acidity - 3D ripping machine