When you think of precision application of crop protection products, you probably think of techniques such as optical spot spraying or other advances in technologies that enable precise delivery and improved targeting. Generally, these techniques can result in substantial savings in crop protection inputs.

Numerous commercial systems and options are available that help target existing weeds, whether in fallow or within the crop.

What if you could do the same with the placement of pre-emergent herbicides by selecting and applying one or more products and delivering them at varying rates according to zones within a paddock in ways that optimise performance, safety and return on investment?

First, would you?

Second, what benefits would it bring?

Third, how would you do it?

These are some of the questions that a project led by Syngenta Australia will explore as part of a new investment by GRDC that focuses on next-generation precision agriculture technologies.

This work will complement other GRDC projects focused on site-specific weed control led by the Australian Herbicide Resistance Initiative, New South Wales Department of Primary Industries, Nufarm, Bayer Crop Science, Data Farming and others.

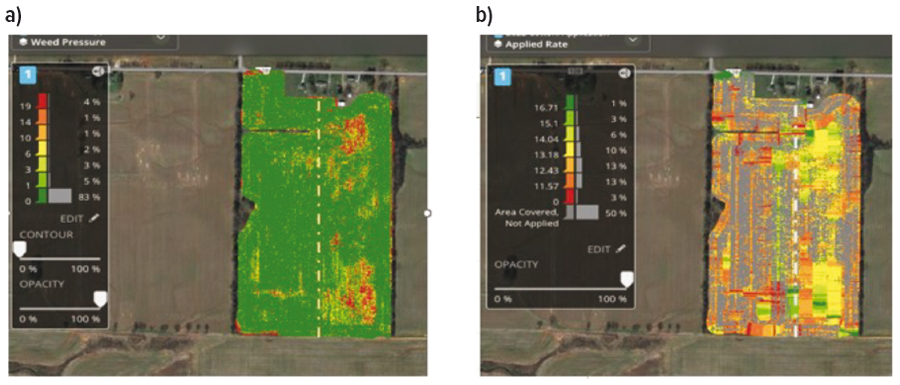

Figure 1: Results from large-scale overseas trials by Syngenta showing the value of applying the right pre-emergent herbicide product, at the right dose, to the right part of the field. Image (a) shows a weed pressure heat map and image (b) the ‘as applied’ map for the same field. The left-hand side of the field was treated with pre-emergent herbicides tailored to field zones. The right-hand side was treated with a blanket pre-emergent spray. The tailored pre-emergent prescription resulted in 17 per cent of the areas treated with a post-emergent product, whereas 50 per cent of the total area was treated following the blanket spray. These results have been replicated in various fields and crop scenarios. Source: Syngenta

The challenge

Currently, pre-emergent herbicide delivery is based on applying a single dose of one or more products in a tank mix. Typically, these are applied as a blanket spray, meaning the whole paddock is treated the same irrespective of soil characteristics or weed seedbank.

An inherent limitation with such an approach is that it locks in the rate and ratio of the individual or tank mixed products and assumes that all parts of the paddock require the same rate. This is generally not the case.

The same varying paddock conditions that influence crop establishment and development will also usually influence the performance of pre-emergent herbicides.

A new approach

This project will use modified direct injection and other commercially available technologies to test the feasibility of tailoring pre-emergent herbicide applications to paddock-based data.

The approach views the paddock relative to zones based on the same factors that influence pre-emergent herbicide performance. These include:

- the properties of the chemistry used;

- how the chemistry interacts with a range of factors, such as need for incorporation, rainfall, soil type and the rate used; and

- characteristics of where the product is used, specifically the soil’s physical and chemical characteristics that could directly influence efficacy, safety and persistence.

Geospatial data will be used to derive the variable rates and create a prescription map for pre-emergent herbicides.

Additionally, Syngenta is partnering with RDO Equipment, which has made a multi-point direct injection sprayer (MPDIS) that will be used in large-scale strip trials across Australia. This sprayer allows multiple pre-emergent products to be applied in a single pass at varying rates according to the requirements of the underlying zones.

Technology development

Caption: Rob Battaglia of Syngenta Australia. Photo: Syngenta

Caption: Rob Battaglia of Syngenta Australia. Photo: Syngenta

Other existing enabling technologies will also be explored for limited but potentially useful variable-rate pre-emergent herbicide application.

Liquid direct injection is one of the enabling technologies that supports variable dosing across a boomspray.

With direct injection, product rates can be dialled up or down and aligned with a prescription map that can be derived from one or multiple layers of information.

Single-point injection systems have been on the market for some time but are inherently flawed due to the chevron effect, which introduces a lag between the product application spike reaching the periphery of a boom. This can result in uneven dosing.

To minimise the chevron effect, the experimental sprayer will have multiple direct-injection points to reduce the lag after the product spike leaves the mixing chamber and exits the nozzle.

A direct injection gives the most flexibility for the large-scale trials. However, the project will investigate the feasibility of using other systems and technologies such as autonomous platforms and dual-line systems to achieve a similar outcome.

The field test sites will host field days across Australia in 2024. Dates and locations will be circulated closer to the time.

More information: Rob Battaglia, rob.battaglia@syngenta.com, 0418 452 356