Snapshot

Farm managers: Paul and Shirley Tognetti

Farm owners: David and Rebecca Hurst

Farm location: ‘Myee’, Grenfell, NSW

Farm size: 2550 hectares

Area cropped: 2100ha

Average annual rainfall: 595 millimetres

Soil types: light sandy loam, red loam, black clay

Topography: slightly undulating

Soil pHCa (calcium chloride): 5.5 to 6

Enterprises: grain and store lambs

Typical crop sequence: wheat/canola/wheat/canola

Crops and varieties: Beckom , LRPB Major , Sunmaster , LRPB Raider

and LRPB Mustang wheat; Pioneer® 44Y94CL, 45Y95CL, Optimum GLY® PY525G, PY520TC and Hyola® Blazer TT canola

The obvious discrepancy between a uniform starter fertiliser rate and widely varying yields across a farm became the catalyst 15 years ago for a husband-and-wife farm management team to begin adopting precision farming.

Today, precision farming is central to Paul and Shirley Tognetti’s decisions each season for planning and applying crop inputs. Paul and Shirley manage ‘Myee’, a 2550-hectare property west of Grenfell, NSW, for South Australian growers David and Rebecca Hurst.

A 2024 prescription map for mono-ammonium phosphate (MAP) for one paddock on the farm Paul Tognetti manages west of Grenfell, New South Wales. Photo: Nicole Baxter

A 2024 prescription map for mono-ammonium phosphate (MAP) for one paddock on the farm Paul Tognetti manages west of Grenfell, New South Wales. Photo: Nicole Baxter

Their starting point was the observation in 2009 that while they were uniformly applying 80 kilograms per hectare of monoammonium phosphate (MAP) across the farm, subsequent yield maps showed considerable yield variation.

After a few people in the Grenfell district started using the firm Precision Ag to source satellite imagery in 2016, Paul hired the company to complete an electromagnetic (EM38) survey to identify differences in soil types and see if these correlated with yield.

When representatives of a local agronomy firm, Delta Ag, visited Canada to explore an arrangement with a precision agriculture company and returned with Farmers Edge, Paul and his agronomist, Jenna Brewis from Delta Ag, started working with them.

Back then, the team used Farmers Edge – a digital platform for collecting and analysing data – to collect biomass imagery for zoning paddocks into different management areas according to yield potential.

Paul wanted to improve farm efficiencies by placing inputs in areas that generated the highest return and optimise yields according to seasonal conditions.

“Farmers Edge was cost-effective for annually collecting soil tests on every zone of every paddock plus supplying other information,” he says. “I sourced some good information and we grew some high-yielding crops – but then Farmers Edge pulled out of Australia.”

Supplier change

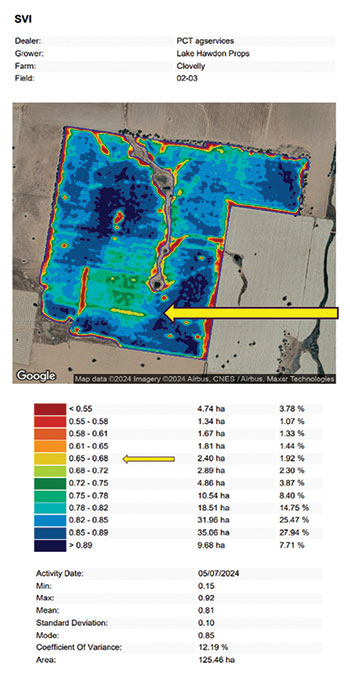

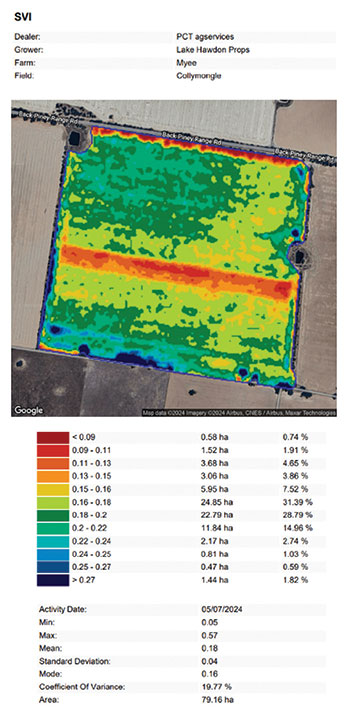

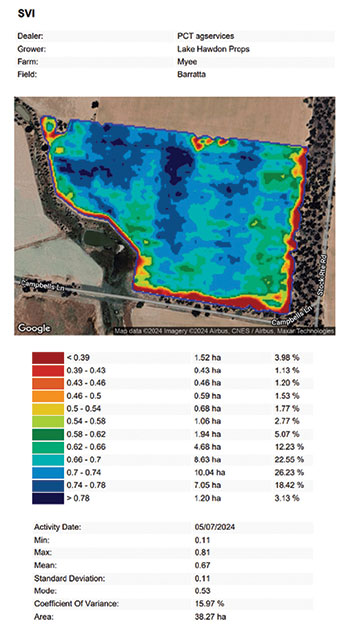

Paul switched to PCT Agcloud, and the data collected has been used to set up soil management zones using the results of the EM38 surveys gathered in previous years.

Soil tests are collected to determine plant-available phosphorous and pHCa, which produce different prescription maps for variable rate application.

He says data analyst Russell Bate from Harden gathers the satellite imagery to examine crop biomass, which is validated with deep nitrogen soil testing to determine nitrogen needs.

“We then look at paddocks and, based on history, estimate what we believe the paddock should yield, and refine our predictions accordingly,” he says.

“We apply inputs to the grain yield we believe we can achieve in each area of the farm.” Now that he is measuring nutrient and ameliorant needs, Paul is more confident in applying higher rates of urea to achieve higher yields.

Automated recording

Evolving machinery options have also assisted Paul and Shirley’s PA management. When John Deere started installing modems in tractors, it meant the driver no longer had to save recorded data on memory sticks.

Now, the maps and data are automatically saved to the tractor manufacturer’s cloud-based platform.

For sowing, Paul selects paddock boundaries, varieties, sowing rates, fertiliser rates and prescription maps, and sends the work plan to the tractor.

“Earlier this year, Jenna set up some trials, and we asked Russell Bate to integrate a urea trial into one of the paddocks. He set it up on the PCT Agcloud platform, which converts it to a prescription map that the John Deere controller reads. The operator just has to drive,” he says.

“This year, we have MAP, urea and canola sowing rate trials, which, when harvested, will be sent to Russell for analysis and reporting.”

Figure 1: Canola sowing rate trial.

Source: Paul Tognetti

Canola sowing rate

The canola sowing rate trial is exploring the viability of planting 2kg/ha of seed instead of 2.7kg/ha of seed (Figure 1).

Paul runs an Ausplow Auseeder deep blade system (DBS) seeder set on 30-centimetre row spacings.

“Hybrids are great varieties, but they are a large upfront cost. We target 30 plants per square metre, and some varieties require a sowing rate of 2.7kg/ha to achieve that, working on 95 per cent germination and 80 per cent establishment,” he says.

Paul calculated that a paddock sown at 2.7kg/ha costs $100/ha, with a 103 per cent establishment rate and 31 plants per square metre.

He is trialling 2kg, which costs $74/ha with an 89 per cent establishment and 27 plants per square metre. This could save $27/ha in seed costs, which will be checked at harvest to measure the effect on grain yields.

“We want to determine if we can decrease our sowing rate without affecting yield.”

Paul prefers to grow hybrid canola varieties because of their yield advantages. This year he grew Pioneer® 44Y94CL, 45Y95CL, Optimum GLY® PY525G, PY520TC and Hyola® Blazer TT.

In early 2023, Paul asked Delta Ag to install five Hussat moisture probes and automated rain gauges. These send soil moisture and rainfall data to Paul’s mobile phone. “If we want to drive the system with nutrition, we need to know when we can do it confidently.”

Figure 2: Urea rate test strip at sowing.

Source: Paul Tognetto

Protein monitor

A John Deere HarvestLab™ 3000 protein monitor was bought for one harvester shared between ‘Myee’ at Grenfell and David and Rebecca Hurst’s farm at Lake Hawdon near Robe in SA.

The data captured, along with deep nitrogen tests and biomass maps, aims to improve the efficacy of nitrogen decisions.

In November, David brings the harvester from SA to work alongside the harvester based at Grenfell.

If the crop is ready to harvest in SA and crops are left to reap at Grenfell, one harvester is sent back to SA.

Urea rates

Another trial implemented on ‘Myee’ this year explores how much urea can be applied at sowing to reduce one pass of the fertiliser spreader.

The base urea rate for the test area is 50kg/ha, with two treatments of 100kg/ha and 130kg/ha.

When it was implemented, Paul says satellite imagery from the paddock showed a significant variation in crop biomass (Figure 2).

Figure 3 shows the effect of 130kg/ha of urea applied at sowing (on the left of each photo) and the effect of 50kg/ha of urea (on the right of each image) applied at sowing.

To date, Paul says it seems unlikely they will be able to reduce one pass of the fertiliser spreader but says it will be interesting to see the harvest yield results. “The high rate doesn’t look that bad unless you compare it to the crop biomass from the lower rate.”

Figure 3: Urea at sowing 130kg/ha (left in both photos) versus 50kg/ha (right in both photos).

Source: Paul Tognetti

Phosphate rates

The third trial this year is exploring variable rate MAP on canola. Paul applied 120kg/ha of MAP to 69 per cent of the paddock, 118kg/ha to 24 per cent, and 50kg/ha to seven per cent.

He believes the results indicate the phosphorous replacement strategy calculated by PCT Agcloud is working because there is no significant difference between the canola biomass for 120kg/ha of MAP and 50kg/ha of MAP (Figure 4). Yield results will be analysed to determine the response. “Precision agriculture has allowed us to improve the efficiency of our input application, especially with phosphorous and lime,” he says.

“We’re still learning about variable rate nitrogen, and I want to see if PCT Agcloud can develop gross margins for each zone to see where we are generating the biggest return on investment.”

Figure 4: Monoammonium phosphate test strip.

Source: Paul Tognetti

Benchmarking group

After hearing Agripath director Simon Fritsch speak at a GRDC Farm Business Update in 2018, Paul joined one of the firm’s comparative analysis groups.

“A few years ago, if you could achieve a 10 per cent return on assets, you would be doing well, but now, if you achieve five per cent, you’re doing well because land values have risen,” he says.

“The comparative analysis has made me look more closely at our input and machinery costs to ensure we generate the best return.”

Trucks are shared with David and Rebecca Hurst’s Lake Hawdon property, which makes machinery investment more efficient.

Paul says fertilisers can be bought in bulk and stored on-farm in silos to take advantage of competitive prices.

For the past 20 years, he has used the independent grain marketing company Market Check, which advises on year-round risk management and offers selling services. He also uses Lachstock Consulting and likes their one-on-one provision of grain marketing advice.

Next year, Paul is keen to try faba beans in the rotation after research results from the GRDC southern NSW farming systems project at Greenethorpe, NSW, showed they lifted returns over five years. Agripath data validated this and showed that the top 20 per cent of growers with the highest return on assets managed over seven years included faba beans in their rotations. After discussions with Agripath director Simon Fritsch, Paul plans to plant 100ha of faba beans in 2025.

More information: Paul Tognetti, myee.paul@bigpond.com

Useful resources: GroundCoverTM story – Study measures faba bean link to system profitability