Gaps in crop rows, erratic crop emergence and dry patches across and down the soil are indicators of non-wetting soil. More common on sandy soils, sandy gravels and forest gravels, non-wetting soil causes problems from the start of the season and can disrupt management for the rest of the year. Operations such as spraying and fertilising paddocks produce suboptimal results when plants are at different growth stages because of non-wetting issues.

Long-term fixes to non-wetting are inverting, mixing and claying by ploughing, spading, delving and clay spreading. These are expensive options and it is unlikely growers can implement them across the whole non-wetting area in one or even several seasons, especially if they have large areas of non-wetting soils.

Shorter-term and cheaper mitigation strategies can be used on some parts of the farm while growers simultaneously fix non-wetting issues using longer-term approaches on other areas of a property. The shorter-term options are useful for getting the crop out of the ground in the season they are implemented. The downside is that results can be inconsistent and, as they are ‘Band-aid solutions’, they need to be repeated every year or two.

Wetting agents and moisture retainers

There is a raft of wetting agents and moisture retainers on the market. They tend to be more reliable on gravels and can be hit-and-miss on sandy soils.

One of the risks when using these products is that when opening rains are good and non-wetting is not as much of a problem as anticipated, the product is not needed (but has already been applied).

Wetting agents can improve crop establishment in non-wetting soil. Photo: Supplied

Wetting agents can improve crop establishment in non-wetting soil. Photo: Supplied

When sowing dry, you cannot predict how much rain will be received when it starts raining. Products are ‘insurance’ in case there is not enough rain to wet up the non-wetting soil, but enough rainfall for the crop to establish when the product is applied.

There is less risk involved with applying these products while sowing after reasonable rain, because growers can gauge paddocks and areas that have not wet up and will benefit from wetting agents and moisture retainers.

Blanket application of wetting products is now less common. It can provide some benefit on highly repellent patches or areas with a high weed burden. Synchronous establishment of weeds makes subsequent control easier.

Banding wetting agents and particularly moisture retainers is more common. Different products have varying requirements on where they should be placed in relation to the seed, so read the label. Some can be applied with the seed and some are compatible with liquid fertiliser.

Research on using products as seed coatings is still in its infancy. Theoretically, the main benefit compared with banding or blanket applications is that less product is needed. Results to date are very mixed. One 2017 trial at Darkan found that using 325 millilitres per hectare as a seed coating produced similar plant density and yield as applying one to five litres per hectare on top and within the furrow.

To date there has been much more research into banded wetters than seed coatings, and other factors such as impacts of seed placement and handling efficiency are being worked out. Anecdotally, some growers have found in-furrow application worked better than seed coating; others found the coating makes seed handling more difficult.

As some wetters can be toxic to seeds only a small amount is used as a seed coating, limiting the impact of the wetter on the soil directly surrounding the seed.

On-row sowing

Sowing on or very near to last year’s crop row lets the crop access old root channels. Water infiltrates more easily into these ‘preferred pathways’ than the surrounding repellent soil, giving the crop a better chance of establishing. In turn, wetter furrows also help reduce repellence by making conditions friendlier for wax-degrading bacteria.

Obviously, this method only works in no-till systems where there are remnant stubble and roots. If you are not currently using no-till methods, or have been removing stubble each year, it will probably take a few years to see improvements in crop establishment.

Compared with wetting agents alone, on-row sowing shows more promise across a wider range of soil types and repellence severity. Research in South Australia found that adding a wetting agent had little impact when on-row sowing, but did offer small yield benefits (0.22 tonnes per hectare) over near-row sowing.

Like most treatments for non-wetting, on-row sowing is more effective when the soil is dry. A 2015 Pingrup trial found significantly increased crop emergence when dry sowing, but little impact with wet sowing.

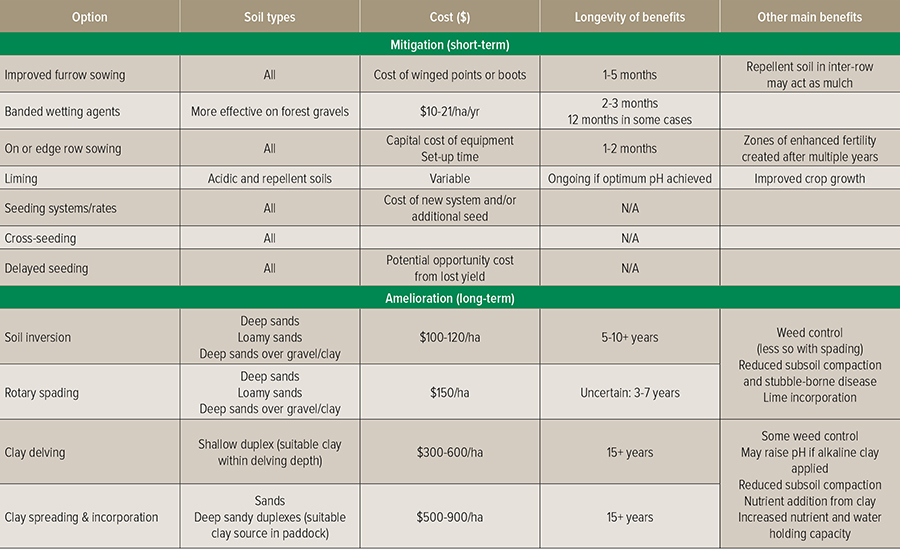

Table 1. Summary table of short and long-term mitigation options for non-wetting soils. (Built on and adapted from Roper et al.2015.)

The main challenge with on-row sowing is that it is difficult to do well. You need Real-Time Kinematic (RTK) guidance (two centimetres accuracy) although, even with this, the bar can drift. If the bar drifts too much into the non-wetting inter-row, crop establishment can be very patchy. This is why cross-seeding is an easier option (covered below). Steering on the bar with an additional receiver and an active guidance system helps markedly and some growers use the stubble as a guide. A degree of skill and a high attention to detail is needed to set up and implement these systems.

It is important to make sure the tynes are evenly spaced across the bar, otherwise on-row sowing will not be repeatable unless you stick to the same seeding pattern every year.

High stubble loads can be a problem, particularly when the stubble gets caught on the tynes. Poor seed placement can exacerbate establishment issues, especially with small seeds such as canola.Harvesting at ‘beer can’ height minimises this.

From a crop protection angle, there are both negative and positive implications for on-row sowing. Some trials have found sowing on the row helped suppress grass weed populations. Stubble pathogens, root disease and foliar fungal infections, on the other hand, can be a bigger issue, particularly if growing the same crop consecutively.

Cross-seeding

Cross-seeding – sowing at a different angle to the last crop – captures some of the benefit of on-row sowing whenever seeds are placed on or very near last year’s rows. As there is still a large amount of seed not placed near last year’s rows, there will still be establishment issues. Cross-seeding is becoming more popular as it is easy to do and improves stubble handling and trafficability.

Cross-seeding means deviating from wheel tracks and increased compaction risk. Growers are using a range of cross-seeding angles – up to 45 degrees. Bigger angles tend to improve trafficability but can nearly double the trafficked area in the paddock.

Delayed seeding

One approach for the worst water-repellent areas is to wait for opening rains and then seed. Research has repeatedly shown that disturbing non-wetting soils when they are dry makes repellence worse and water infiltrates more slowly. Dry seeding requires even more rain post-seeding to overcome that repellence than if seeding after it has rained. Even one day can make a difference. Figure 1 shows a 12-hour sowing difference.

The missed yield potential from early sowing is compensated for later by more uniform crop establishment. Saving water-repellent sections to the end of seeding can also mean better weed control. If the soil wets up and weeds germinate, you can use a knockdown before seeding.

As it is impossible to seed everything after sufficient rain, leaving the worst non-wetting paddocks until last could be an option.

Seeding points when furrow sowing

Furrow sowing grades the soil, shifting the water-repellent soil out of the furrow and into the ridges. The repellent ridges help harvest water into the furrow, improving the chances of infiltration. Winged points do a better job of making these furrows. Knife points, especially when dry sowing, tend to make things worse by funnelling the dry, repellent soil into the furrow.

Theoretically, if growers only have knife points and also have severely repellent sand, it is best to seed crops faster as soil is more likely to be thrown out of the furrow. However, this theory needs to be tested with further research and validation.

Deeper furrows

In principle, deeper furrows mean more water harvesting from taller ridges, and/or an ability to sow into deeper moisture. Care is needed with this strategy as deeper furrows can increase erosion risk by moving more loose sand to the ridges.

No-till makes smaller furrows over time, but has the benefit of more soil cover and options for on-row sowing.

Deep furrow till sowing

Recent trials in South Australia have looked at deep furrow till sowing, which uses longer knife points to reach 230 millimetres deep and lift moisture into the seed zone. The method was tried with near-row sowing by using a 120mm longer knife point and side-banding the seed. Inter-row sowing was achieved by operating 120mm deeper and setting the seeding boot 120mm higher. Both methods also used a wetting agent.

Inter-row establishment improved by 74 plants per square metre, while establishment decreased for near-row sowing. Researchers suggest near-row sowing was less effective because the long, steep knife points needed to reach 230mm were less effective at bringing moisture up, while the extra disturbance affected seed placement.

Deeper seeding

Long-coleoptile cereals can be sown closer to subsoil moisture and effectively bypass the repellent topsoil, at least for establishment. There are genetics being researched with coleoptiles up to 150mm long, however most commercial varieties have a coleoptile between 60 and 80mm.

Researchers are working on genetics to improve establishment in deeper sowing. Note that some fungicides (particularly triazole fungicides) can shorten coleoptile length, as can some herbicides (trifluralin and pendimethalin). Planting a variety deeper than the coleoptile length can cause ‘silly seedling syndrome’, where leaves grow under the soil surface but do not emerge.

Seeding systems

Seeding systems that distribute seed more widely can improve establishment. Ribbon sowing involves planting seed evenly across an entire band (ribbon), usually 50 to 100mm wide. Paired-row seeding systems place two rows of seed into either side of the wall of the seeding furrow (usually 75 to 100mm apart), effectively doubling the number of crop rows in the paddock. The theory is that because non-wetting is uneven, spreading seeds increases the chance of seeds ending up in areas that wet up more easily.

Press wheel choice is also important. Choose a press wheel that keeps the furrow well-formed, minimising the chance of non-wetting soil falling back into the furrow. V and U-shaped wheel profiles work better than flat profiles in this instance.

Higher seeding rates

Simply sowing more cheap seed can improve establishment. Trials increasing wheat sowing rates from 60 to 120kg/ha saw establishment increase from 56 to 77 per cent. The caveat was that higher seed numbers did not always translate into more yield, especially on soils with low water holding capacity.

Liming to boost beneficial bacteria

If soil acidity is also a problem, consider liming. The pH boost encourages wax-degrading bacteria (actinobacteria), which lower water repellence severity. A four-year trial at Woogenellup found that liming water-repellent acidic soil increased the populations of wax-degrading microorganisms tenfold. Water repellence was subsequently reduced for the duration of the trial. Where water repellence is the only constraint, lime is unlikely to be an economical option.

Burning stubble

The short, low temperature of crop stubble burning is unlikely to affect water repellence except perhaps in the top few millimeters of soil, which are not being sown into anyway. The effect of fire and increased soil temperature on water repellence is variable. Lower temperatures can increase repellence – research on oven-dried soil samples found drying soil samples at higher temperatures increased water repellence (Dekker et al. 1998). Hotter, more intense wildfires can reduce water repellence, but stubble burning is unlikely to generate enough heat for this to work.

Some work on burned stubble paddocks found burning prevented preferred infiltration into old root channels, possibly because the crowns as well as the roots are needed for the preferred pathways to work. Burned paddocks did not recover well once returned to no-till and stubble retention. Establishment is still better in unburned/stubble-retained plots.

*This article was produced as part of the GRDC ‘Maintain the longevity of soils constraints investments and increase grower adoption through extension – western region’ investment (PLT1909-001SAX). This project is extending practical findings to grain growers from the five-year Soil Constraints – West suite of projects, conducted by the WA Department of Primary Industries and Regional Development, with GRDC investment.

References

Dekker LW, Ritsema CJ, Oostindie K & Boersma OH 1998, "Effect of drying temperature on the severity of water repellency", Soil Science,vol. 163, pp. 780–796.

Roper MM, Davies SL, Blackwell PS, Hall DJM, Bakker DM, Jongepier R & Ward PR 2015, "Management options for water-repellent soils in Australian dryland agriculture", Soil Research, vol. 53, pp. 786–806.