Snapshot

Ben and Fiona Hobley; Jarrad and Ellaine Hobley; Neil and Chris Hobley

Farm size: 8300 hectares (including 7000ha crop)

Average annual rainfall: 350 millimetres

Cropping: wheat, barley, canola, oats, lupins

Soil types: duplex sand over clay, gravels, loams

Soil pH: 4.5 to 6.0

Nyabing grower Ben Hobley is dipping his toes into the science of soil amelioration in an attempt to solve the multiple constraints of compaction, soil acidity and water repellency on his many different soil types.

Deep-ripping, delving and spading are all being trialled and tested on his property in the state's southern wheatbelt to better understand which strategy will provide the best yield responses across his wheat, barley, canola, oats and lupin crops.

To specifically target soil compaction and acidity, Ben, his brother Jarrad and his father Neil, have been running paddock-scale, deep-ripping trials.

While it is still early days, the trial data is showing promise in terms of yield responses and a positive return on investment.

Lime has been applied for many years across the Hobleys' property, with rates increasing from two to four tonnes per hectare over the past four years. Until now, lime has only been applied to the topsoil. But Ben is hoping to see significant improvements to his subsoil pH after pushing the lime down through the soil profile in the amelioration treatments.

In 2017, Ben deep-ripped paddock strips to a depth of 400 millimetres in two different locations and across varying soil types - with parallel control strips to compare the data. These were sown to wheat in 2017, with yield increases across both trials averaging 199 kilograms/ha above the control.

In 2018, the treatments were planted to barley, with even greater yield increases - an average of 346kg/ha - compared to the controls.

Ben was sufficiently encouraged by these two-year responses to conduct more trials, this time using a very-deep-ripping machine to rip to depths of 700mm in some places. "We are waiting to see how these new trial strips respond this season as to whether we will look at investing in deep-ripping in a bigger way across the farm," he says.

"Being able to deep-rip is seasonally dependent and we can't do much if we have a very dry start to the year - as we did in 2019."

To protect any future investment in deep-ripping, the Hobleys run a 12-metre controlled-traffic farming system and while Ben admits it's not yet perfect - with dual wheels still on the harvesters and an 18-metre seeder bar - it will go a long way towards reducing re-compaction issues.

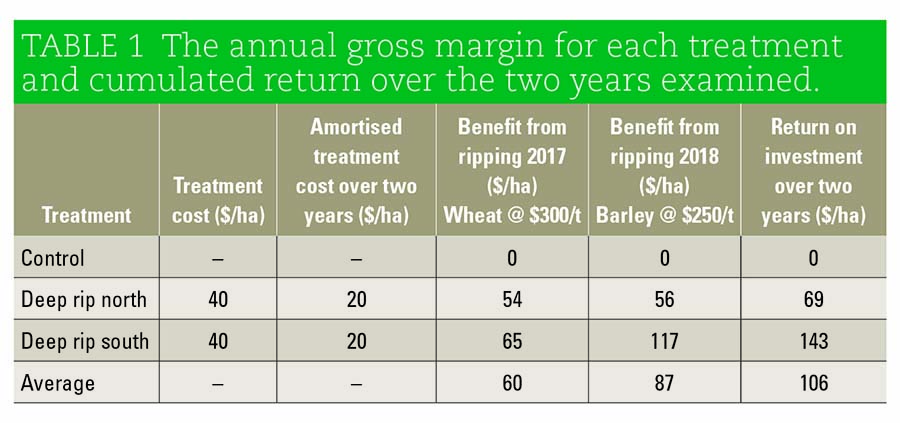

Data from Ben's trial work has been analysed by AgVivo consultant Joel Andrew as part of a GRDC-invested project considering the economic return on investment in deep-ripping. Mr Andrew says the economic analysis is showing deep-ripping is a profitable strategy for the Hobleys. "There was an average net benefit of $106/ha across the two years, from the deep-ripping treatment in this paddock over the control, which is economically significant and makes the deep-ripping practice worth the effort, especially if the yield benefits continue over time," he says.

But he says the real story will be told after several years of yield data are collected. Mr Andrew also measured soil strength in the trial period. He says crop plant root growth starts being inhibited at soil strengths of 2500 kilopascals and above, and these levels were reached consistently in the control (non-deep-ripped) treatments at depths of between 150 and 300mm.

"But soil strengths increased to levels of 4500 to 5000kpa at (a depth of) around 500mm, which suggested there is a compaction layer at this depth," he says.

"Results from Ben's 2019 trial work, where he has ripped to down to 700mm, will tell us the true story of how much this compaction layer is restricting plant root growth and, ultimately, yield. Conversely, soil strengths in the deep-ripped treatments were maintained below 2500kpa at depths of up to 400mm, which can almost certainly be attributed to the deep-ripping process."

Ben believes the deep-ripping treatments were visually more robust than the control in this season also and he expects there will be another positive yield response when the data is analysed, meaning an even bigger return on investment.

The Hobleys also trialled 30ha of delving and spading in the 2019 season to see whether this treatment would alleviate soil water repellency. Yield results from this trial are not yet finalised, but Ben says the crops looked better than the unspaded and undelved areas, particularly after such a dry end to the season.

"We picked up some rain at the very end of September and the crop in this delved and spaded part of the paddock seemed to hang on much longer than the rest of the paddock," he says.

"This is another strategy that we will now consider to combat water repellency, given that these crops looked so much better than the control - particularly at the end of the season."

As president of the Nyabing Farm Improvement Group, Ben is keen to see more amelioration research trialled in his area, with growers in this southern wheatbelt region dealing with multiple soil types across their properties.

"There isn't going to be a one-size-fits-all approach to our constraints in this part of the wheatbelt," he says,

"But we are always on the hunt for flexible strategies that can be applied to such a diverse range of constraints and soils to increase yields."

Ben has recently carried out a ground-based radiometric survey to help identify soil types that could respond to various amelioration methods. "We have always known we have many different soil types, but we are now objectively trying to define them within certain paddocks, and with this survey information we can match anything we do in the future - be that liming or deep-ripping or other soil amelioration treatments - to certain soil types," he says.

More information: Joel Andrew, joel@mapiq.com.au