Using social media networking, growers across the country saved thousands of dollars last harvest by sharing stories, suggestions, photos and advice on ways to minimise grain losses.

A GRDC-invested project, the @harvestloss Twitter handle initiated and managed by Planfarm’s Peter Newman, has connected growers across Australia, helping them to trial different ways to set up a harvester to reduce the amount of grain thrown out to the paddock with the chaff.

A poll on the @harvestloss forum found growers saved, on average, $9200 by reducing their harvest losses during the 2019-20 harvest season, simply by measuring with drop or throw trays, calculating these losses in the Harvest Loss Calculator and adjusting their harvester settings.

Using @harvestloss tweets and poll figures, Mr Newman estimates at least 700 growers used drop trays last harvest to measure grain losses, translating this individual average saving into an industry-wide saving of about $6.4 million.

He anticipates more growers will invest in the drop tray technology and use the Harvest Loss Calculator this coming harvest.

“The $9200 was an average of all the respondents and, in fact, the poll also showed that many growers were making much bigger savings than that when they reduced their grain losses. Almost 20 per cent said they saved more than $20,000,” Mr Newman says.

“Also, those calculated losses are only what is actually being measured and reported on Twitter. The real amount of grain we lose out the back of the harvester is far greater and a huge loss to the industry.”

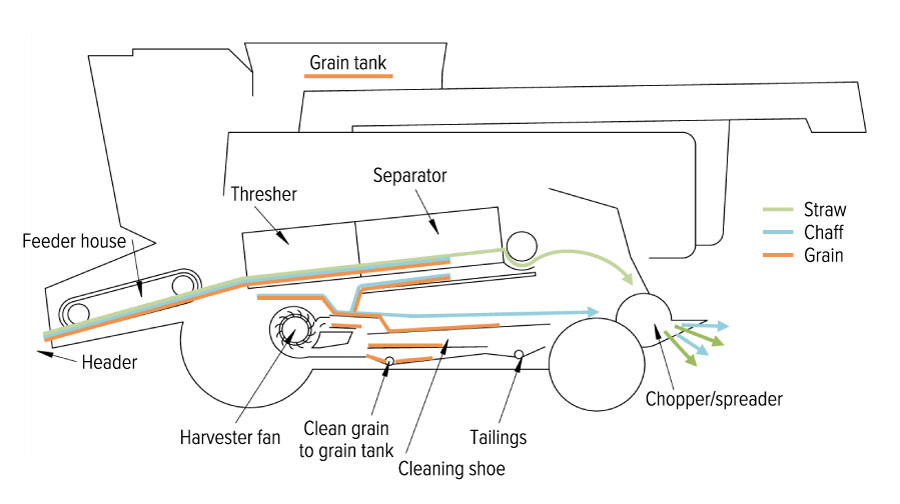

Inside your harvester. Photo: Nick Berry, Seed Terminator.

Mr Newman says he always advises growers to measure losses, using a drop tray or similar product, on a regular basis throughout the harvest.

“Sometimes it might take a lot of measuring early in the harvest, using a trial-and-error approach with your harvester set-up, to get those losses down to an acceptable level,” he says.

“At the very least, drop trays – or other measuring technology – should be used with each new paddock or with each new change of variety. A change in weather conditions is also a good time to stop and measure your losses.”

Growers Luke and Greg Moroney, Brimpton Lake, South Australia

When strong wind in late 2019 blew around their canola windrows, Brimpton Lake growers Luke and Greg Moroney thought the best way to harvest this swathed canola was to use their standard harvester comb instead of their pick-up front.

After changing fronts, the father-son team saw their canola losses drop so significantly on the monitor in the cab that they thought it must have been an error.

“We knew we had some harvest losses, but we believed at the time we had those losses at a satisfactory level,” Luke says.

“After changing over the fronts and seeing the monitors adjust so rapidly, we wanted to make sure it wasn’t a false reading. I didn’t believe it at the start.”

The Moroneys tested the grain losses using a drop tray, finding the numbers had reduced by 40 to 50 kilograms per hectare, which Luke has since translated into a saving of $30/ha on just the canola.

He admits they are still not totally sure what occurred after they changed the fronts to see such a major reduction in losses, but suspects it was related to the amount of material going over the sieves.

Luke and Greg Moroney From Brimpton Lake, South Australia. Photo: Evan Collis.

“I think with the rows blown about, there was less plant material going through the machine and we weren’t overloading the sieves as much using this front,” he says.

While they will continue to swathe their canola and use their pick-up front, the Moroneys now have a much better understanding of how to make adjustments on their harvester to account for the plant material going over the sieves.

The Moroneys had been using drop trays throughout their harvest period, measuring the losses and making adjustments to their harvester concaves to reduce the amount of space available in the rotor.

“Most of the threshing happens going up the throat (feeder house), so I don’t think we need a huge amount of space in the rotor,” Luke says.

“We closed the concave right down to start with, until we saw some rotor losses, and then we opened it up section by section until we got to the point where the rotor losses were minimal and there wasn’t too much material going over the sieves.”

Canola losses for their 2019 harvest were ultimately less than two per cent.

The Moroneys crop 2800ha of wheat, canola, barley, lupins and vetch. They have a “mixed bag” of soil types, from good loams to deep sands over clay, plus some free limestone ridges.

Their growing-season rainfall is about 325 millimetres.

They use the drop trays to measure the losses in their wheat, barley and canola crops – finding similar savings in their cereals to the canola.

“We use the drop trays every time we move into a new grain, or if the conditions (such as wind or moisture) change significantly,” Luke says.

Last harvest, the duo used the drop trays at the beginning of their cereal harvest, seeing losses of 2.5 per cent at the start.

“It was a trial-and-error approach. We adjusted fans and sieves until those losses were sitting at around one per cent for wheat and barley, which we calculated to be around 30 to 40kg/ha, with savings of $13/ha, across all the cereals.

“When you translate it into a dollar amount, it’s a pretty large saving.”

Grower Geoff Cosgrove, Mingenew and Arrino, Western Australia

Even if grain losses are at acceptable levels, measuring these losses can provide confidence to improve harvest productivity levels, according to Mingenew and Arrino grower Geoff Cosgrove.

“Our losses weren’t significant to start with – the harvest conditions were kind to us – and we really only needed to make minor adjustments to the rotor speed settings to get both the threshing rate right and the sieves working well,” Geoff says.

Grain losses in all crops were about one to two per cent throughout their harvest period.

“We could have got these losses down even further if we wanted to, but we would have had to compromise productivity, which comes with its own costs,” he says.

For the Cosgroves, slowing down their harvesting speed to reduce these losses even more was not an option given the area they have to cover.

“Using a drop tray to measure our losses gave us the reassurance that we had most of the settings right and allowed us to push our machines a bit harder to cover more hectares in a day than we normally would have,” Geoff says.

“When we measured the canola losses, we had about 10 to 15kg/ha going out the back and, since we were prepared to accept levels up to about 30kg/ha, this meant we could increase our harvesting speed.”

Geoff and his wife Fiona farm 10,000ha with Geoff’s brother Andrew and their father Gary, planting wheat, barley, canola and lupins. Some of the property is close to the coast, meaning damp conditions after sunset can change the harvesting environment.

Mingenew grower Geoff Cosgrove. Photo: Evan Collis.

“This was the time when we would go in and double-check – when the conditions changed and there was more moisture in the air – so having access to the drop trays gave us the ability to harvest longer days, slowing the speed down slightly after sundown, still knowing we were keeping those losses down at low levels,” Geoff says.

In their wheat, Geoff says their losses were first measured at about 50kg/ha, but by adjusting the rotor settings and ensuring both the threshing and sieve speeds were accurate, they were able to get losses down to just 10kg/ha, or less than one per cent.

Despite purchasing two harvesters at the same time – both being the same brand, model and year – different adjustments had to be made on each machine.

“Theoretically, the machines were identical, but I guess having that human interaction with different drivers meant the settings needed to be slightly different on each to have this loss/productivity balance,” he says. “It just goes to show that there is no one-size-fits-all approach.”

The Cosgroves tested front shatter losses with the drop tray on their lupins and canola but found this a tricky exercise. “What you have to do to measure front losses is put the tray in the crop before the machine gets there, then stop the header just after the front goes over it and before the chaff out the back runs over it.

“We did run into some problems with things like wheels on the back of the draper fronts, and also being very specific about finding an area that is representative of the front’s overall performance.”

Using the separator bucket that came with the drop tray, the Cosgroves were also able to see that the sample was generally clean when it came to weed seeds.

“We could see most of the ryegrass seeds going off the back of the sieve and on to the chaff lines – so it was a useful tool in giving us the confidence that we were managing our weeds as well as managing grain losses.”

Grower Clayton South, Wagin, Western Australia

Creating extra airflow to allow plant material to almost float off the sieves, particularly during the warmer hours of the day, was one of the strategies used by Wagin grower Clayton South to reduce grain losses in his barley crop. “It was a tip from a pre-harvest machinery workshop we attended,” Clayton says.

“We harvested the first few days without a drop tray. When the drop tray arrived, we trialled the losses using the factory settings, compared to opening up the sieves, and there was a clear benefit,” he says.

The key message Clayton and his team took away from the pre-harvest workshop was “get more air moving through the machine”.

“Since the grain is heavier than the straw and chaff, the more air flowing through the system will allow the grain to sink through the sieves and the rest of the material to move more easily through the system.”

Clayton South with farm manager Tristan Storer in Wagin WA. Photo: Evan Collis.

With the sieves and concaves closed over, he says, the airflow had almost the opposite impact, with the creation of a whirlpool effect putting pressure on the sieves, which sucked the material down and made it much harder for the grain to push through.

“If the air is trying to get back up through these tighter holes in the sieve, it seems to have a suction effect,” Clayton says.

“Trying to find that perfect airflow rate is the key, and if you open it up too much you can end up letting bits of straw into your bin, which can give you some problems with grain quality and delivery standard.”

Barley losses of 7.5 per cent were reduced to less than two per cent, while wheat losses were down to 0.2 per cent in some parts of the paddock during the middle of the day when conditions were warm, translating into savings of $40 to $50/ha across the property.

Clayton and his wife Polly farm 5000ha east of Wagin, where cool mornings and nights can change the harvesting conditions by the hour.

“It was definitely tougher harvesting in the morning, and we were losing a bit more out the back because the rotor and the concaves weren’t separating the grain from the husks as well as when the temperature was warmer in the middle of the day,” he says.

“We found the only way to stop this was to slow our harvesting speeds down to give the machine a better chance to separate everything during these times.”

Using the drop tray to measure losses also convinced the team they had to stop work earlier in the evenings than they might have in previous harvests.

Trying to find that perfect airflow rate is the key, and if you open it up too much you can end up letting bits of straw into your bin, which can give you some problems with grain quality and delivery standard.

“The nights can get quite cool through November, so we often ended up packing up an hour earlier than we normally would have, because we realised through our regular measuring that the losses were too high to make it worthwhile once the sun had gone down,” he says.

Since the drop trays are easy to use, Clayton says regularly measuring the losses took the guesswork away from his two full-time employees.

Calibrating the harvester monitors with the drop tray results allowed his drivers to get a clear picture at all times about what was happening at the back of the machine.

“Like any farmer, we baulked at the cost of the drop tray, but we quickly worked out that it paid for itself in just the first few days.”

Grower Jarrod Clarke, Bolgart, Western Australia

For Jarrod, Barry and Steph Clarke of Bolgart, using a drop tray to measure losses during their 2019 harvest was a big learning curve but, after saving 344kg/ha of barley, they believe it was worth the investment.

“We knew we were losing some grain out the back. Being on Twitter and seeing all the buzz about canola losses got us thinking that we had better do something about our own grain losses,” Jarrod says.

While the Clarkes knew they were losing some grain, they did not realise just how much.

“When we first tested the barley with a drop tray, the result was a shock,” Jarrod says.

“It was a new experience and made us stop and take the time to get the settings right to make sure as much grain was going into the bin as possible.”

In their barley crop, the Clarkes had an early loss reading of 500kg/ha, but by slowing the fan speed by 40 revolutions per minute and opening up the concave by 2mm, this loss fell to 156kg/ha.

“That 156kg/ha equated to losses of around 4.5 per cent and, even though we would have liked to see this fall to two per cent, just seeing this major improvement as a start was a big win for us.”

Jarrod and Barry Clarke, farmers from Bolgart in WA. Photo: Evan Collis.

It took several days of trial and error for the Clarkes to achieve this result in the barley, but once they got into the wheat, it only took 24 hours to work out the right combination of settings to reduce their wheat grain loss rate to 30kg/ha.

Jarrod says they discovered a difference in the physical distance between the concave and the rotor, compared to what was displaying on the monitor in the cab.

“So that needed to be recalibrated by a mechanic to make sure we were seeing the same thing on the screens as to what was actually happening in the back of the machine,” he says.

The Clarkes farm 2500ha in a high-rainfall region, meaning harvesting in thick crops can sometimes be a slow process.

Higher moisture levels in the early mornings and evenings can mean the regular adjustment of some settings to minimise losses.

It’s a twofold effect really. We’ve added on profit to our harvest budget and we’ve also taken a bit of pressure off the autumn spray program, so we are really happy with the outcome

Early measurements in the canola showed they were losing 150kg/ha, but by making small machine adjustments they were able to get this down to approximately 20kg/ha. “Canola is an expensive crop to grow, so we were really happy to save such a big amount across the program.”

The reduction in their grain losses has also been noticeable in the reduced number of volunteer wheat, barley and canola plants they have had to spray out prior to seeding.

“It’s a twofold effect really. We’ve added on profit to our harvest budget and we’ve also taken a bit of pressure off the autumn spray program, so we are really happy with the outcome.”

Next harvest, the Clarkes will have a new and different brand of harvester, meaning their measuring and adjusting process will start from scratch again.

With the drop tray technology, Jarrod says measuring losses will be an easy process to put in place from the start of harvest.

“We will be measuring regularly now that we know about this technology and have an understanding of what to look for inside the machine to improve the amount of grain we capture,” he says.