Snapshot

Location: Berriwillock, north-west VIC

Enterprise mix: Cropping only

Farm size: 3400 hectares

Soil type/s: Loam to heavy clay

Rainfall zone: Low

Annual rainfall: 340 millimetres

Average GSR: 225mm

Seeding equipment: 18 metre (60 foot) Bourgault 3320 paired-row tyne seeder with root boots on 38 centimetre (15 inch) spacings and a John Deere 1910 three bin tow behind air cart.

Farming across a span of around 20 kilometres, the Renneys manage a no-till cropping enterprise over varying soil types. Each year, 90 to 95 percent is cropped for grain production with the remaining paddocks either sown to vetch for brown manure or hay, or managed as a chemical fallow for moisture conservation.

John sees successful crop establishment as an incredibly important aspect to a cropping system as it has implications on the entire season. He’s looking for “consistent depth and even emergence” as this makes in season management easier with even development.

From years of observations he says that “anything that starts well, does well for the rest of the year” with a better survival rate through what can be pretty tough conditions in their region.

Seeder choice

Johns current seeder was chosen as an updated version of his previous bar. The solid build and strength of the Bourgault bar has proven to be a good fit for the sowing conditions of the property with very few issues and was an easy brand decision when selecting a new seeder.

“The strength of the machine allows for good penetration on hard ground,” John says.

Parallelogram linkages and individual depth control of tynes using press wheels allows even and consistent sowing depths.

“To improve trash clearance, something that is always a challenge, we have the option of having a fourth rank which was chosen when purchasing,” John says.

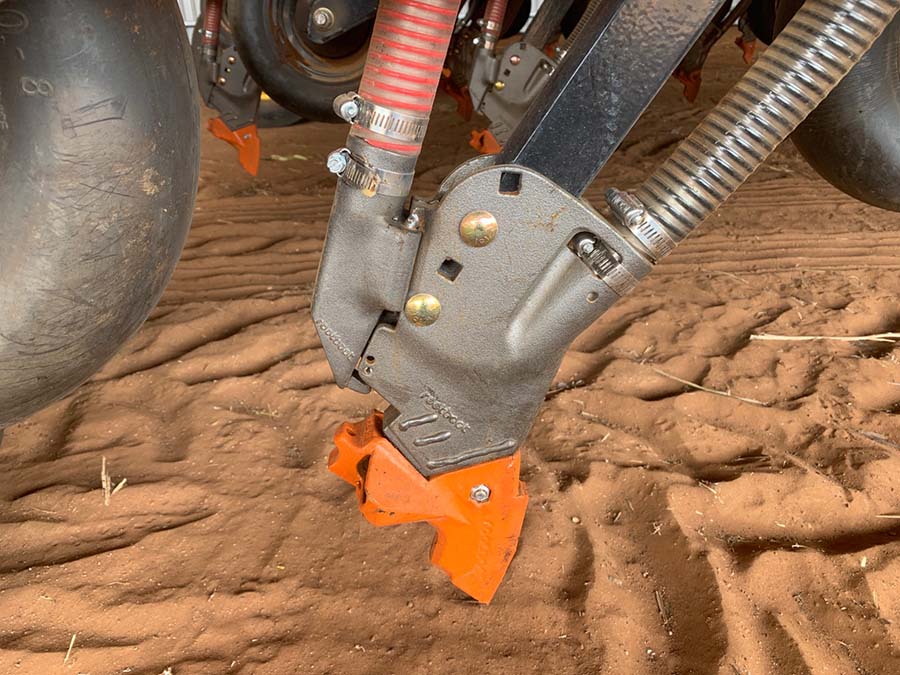

A paired row system on 38cm (15 inch) spacings provides good crop spacings for the environment. Using the ‘root boot’, has provided good fertiliser separation from seed where fertiliser is placed at the bottom of the furrow and seed towards the edges.

“This allows for more urea to be put out at sowing without risking seed burn,” says John.

John's seeder's root boots. Image: Contributed.

While John’s aware that it has the potential for higher maintenance, he says the choice to run a hydraulically driven system provides more reliable seed depth control and metering.

The sowing operation

For the Renneys the sowing operation begins at harvest with stubble management. Rotation planning comes next, with sourcing of quality seed to follow. Sowing rates can be calculated taking into account seed size and germination on occasion, but the Renney’s sowing rates tend to be a standard kilogram per hectare rate adjusted for crop type and again for variety, where there is a significant difference in seed size. For example, Hurricane lentils (small seed) are sown at 35kg/ha where Bolts (larger seed) are sown at 50kg/ha.

“Time invested in seeder setup and monitoring is important to achieving good establishment and can pay off for the season,” says John.

“With the new seeder, an expected four hours will be spent on setup this year with constant monitoring of seed placement and performance throughout the sowing period across different soil types and conditions.”

Seeding depth is kept fairly consistent for most crop types at 2 to 2.5cm. However, when conditions are dry, rather than creating a ledge for seed to be placed on, the soil can shatter from the splitter boot rather than be cut through, resulting in seed close to the surface. In these conditions, slower speeds and slightly shallower depth can reduce this issue. When dry sowing canola, seed is placed slightly deeper to protect against a false break.

Sowing on time is another important aim of the Renney’s program. John says this is done “by the calendar with an eye on the weather at a speed of 10 to 10.5km/hr,” with the goal of having the majority of seed in the ground by mid-May (with the exception of field peas).

“In many cases this means we are dry sowing prior to breaking rain. I keep an eye on the weather as it may change sowing decisions if rain is on the forecast, which would result in crop emerging earlier than targeted,” he says.

Herbicides are applied and incorporated by sowing with John’s seeder, a weed control option very important in the Renney’s system. Speed is managed at sowing to reduce risk of herbicide damage from soil throw from one row to the next.

In some years, particularly following a tough season where unused nutrition can remain in soils, the Renney’s fertiliser rate is varied across a paddock.

“Varied rates are managed through the control system in the cab, this is achieved through zone maps imported into John Deere software. In the past we have also varied seed in this way however, we didn’t appear to gain anything from this,” John says.

The air cart uses a roller metering system driven by hydraulics. Calibration is achieved through the in-cab control system for different roller sizes.

“I’m happy with the performance of this metering. I don’t have an issue with achieving lower sowing rates with canola, but I know sowing large seeds, such as chickpeas, at higher rates can be an issue if the sowing speed is too fast,” John says.

There are no blockage sensors on the seeder so this is checked every time there is a refill.

Managing the challenges

The main challenges to establishment faced at sowing for the Renneys are around stubble management and understanding soil conditions.

Stubble can cause issues with establishment, causing blockages at sowing and variability in seeding depth and amount of seed soil contact when stubble is pulled into the seeding rows. While aware that having press wheels directly behind each boot can increase the likelihood of stubble blockages, the Renneys take the approach that “stubble management for sowing begins at harvest”, John says.

Harvesting low reduces the standing stubble load that is faced at sowing. In conjunction with this, John chose a seeder with four ranks rather than three and has been working on improving the inter row sowing accuracy of his sowing equipment by mounting the GPS unit on the seeder bar.

“This essentially means the seeder is steering the tractor, remaining more consistently in the inter row to reduce stubble contact,” he says. Reduction of sowing speed is also a useful tool to manage stubble at sowing.

The GPS mount on the seeder. Mounting the GPS on the seeder has improved the inter row sowing accuracy of his sowing equipment. Image: Contributed.

"I’ve toyed with the idea of coulters as another option to help with the issue however, they currently remain on the Christmas list,” John says.

With a large portion of the program often sown dry, cloddy soil can be an issue affecting establishment for the Renneys. Clods can be pulled up by the seeder, which causes reduced seed soil contact and uneven depth of seed placement.

“When this is an issue we reduce sowing depth slightly, which manages this to an acceptable level,” John says.

Pests, particularly insects and mice can also impact establishment across the property and these are managed through seed treatments and baiting.

The main disease issue faced at sowing on the property is rhizoctonia. In high-risk areas, such as rises on lighter soils, this is managed by slightly increasing sowing depth.

Three tips for successful crop establishment:

- sow on time;

- get good seed soil contact and

- make sure you have good depth control.

More information: John Renney, 0427 015 711, john.renney@bigpond.com