Snapshot

Growers: Mitch, Craig, Ben and John Henderson

Locations: Berriwillock, Wilkur, Brim and Werrimull, Victoria

Average annual rainfall: 300 to 350 millimetres (Werrimull)

Soil types: sandy loam, medium to heavy clay loam

Enterprises: 100 per cent continuous cropping, chicken meat

Crops grown: Scepter, LRPB Raider, Tomahawk CL Plus and Calibre wheat; PBA Hallmark XT lentils; Maximus CL and Commodus CL barley; Kingbale and Brusher oats for hay

Typical crop rotation: wheat/barley/lentils/oaten hay

Mitch Henderson says innovations for non-chemical weed management are critical in the fight against herbicide resistance.

The 33-year-old, who farms four properties across the Victorian Mallee, applied for a Nuffield Scholarship valued at more than $35,000 after his partner Sharee – and Nuffield Scholar alumni Ashley Fraser from Baker Seeds Co – encouraged him to consider the benefits.

Nuffield Scholars:

- are supported to research a topic of interest;

- travel overseas for a 14-week study tour;

- engage in face-to-face learning and development;

- enter a network of 2000 global alumni; and

- gain access to businesses and individuals usually unreachable.

After applying, Mitch was offered a Nuffield Scholarship with GRDC investment in 2020. However, the COVID-19 pandemic meant he did not complete his travel until 2023.

“Weeds are our biggest challenge, so I thought I’d like to look at what we can do to lower our reliance on herbicides,” he says.

His journey took him through Australia, France, England, Canada, Ireland and the US.

He says some promising developments are on the horizon but “no silver bullets”.

“There was no single technology that stood out as the sole revolution to weed control,” he says. “Rather, there are tools that, in the future, with further development, may be deployed.”

High-intensity light

While in the US, one of the most interesting weed management technologies Mitch saw used light – infrared and blue – to make herbicide-resistant weed seeds unviable.

In Dayton, Ohio, he met Jon and Patrick Jackson of Global Neighbor Inc, who have developed a prototype to kill herbicide-resistant weed seeds using this blend of high-intensity light.

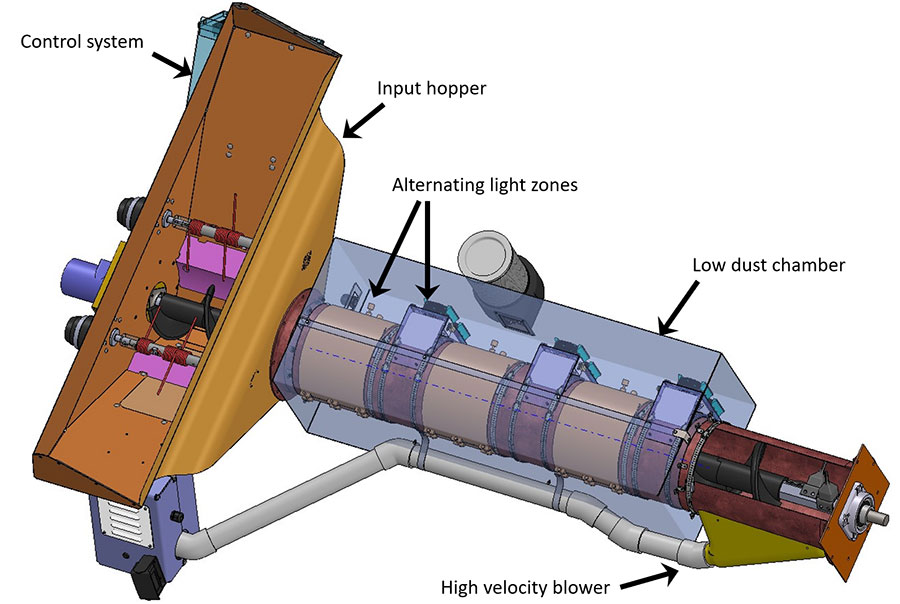

The prototype Weed Seed Destroyer bolts on the rear of harvesters. It captures chaff and weed seeds from the sieves and exposes the seed to different light wavelengths as it travels through a low-dust chamber. In this, weed seeds are exposed to, and damaged by, mid-wave infrared and blue light.

A diagram showing how the Weed Seed Destroyer would fit underneath the chassis of a John Deere harvester. Source: Global Neighbor

Treated material is then blown back into the harvester’s waste stream and deposited on the paddock. From entry to exit, the treatment takes about 1.5 seconds.

“The benefit of the machine is that it only uses two hydraulic hoses and an alternator,” Mitch says.

“It only has a power draw of 7.35 kilowatts (10 horsepower) and the technology, so far, is quite exciting.”

Dr Michael Walsh*, an Associate Professor at the University of Western Australia (UWA), says the technology seems feasible, but currently there is no clear understanding of why this combination of heat and light kills weed seeds and plants.

The Weed Seed Destroyer internal parts. Source: Global Neighbor

With GRDC investment, he is testing a prototype for weed seed control in Australian conditions using wheat chaff and annual ryegrass seed.

“The technology continues in development, and initial test results from the US look very promising,” Dr Walsh says.

“But we need conclusive evidence from our testing to confirm the opportunity for this system in Australian conditions.”

Laser weed control

Another innovation Mitch discussed with owners while in the US was Carbon Robotics’ laser weeder.

He says this automated system was developed for row crops and relies on artificial intelligence and machine learning via 42 cameras to detect and differentiate weeds and crops. The robots use high-powered lasers to kill the weeds.

Mitch says the company claims a 99 per cent weed kill rate, but it only works at 2.5 hectares an hour.

“The biggest limiting factor of the laser weeder is that it only has a four to six-week operation window,” he says. “It cannot be used if weeds exceed 35 millimetres high.”

Electrical weeding

Another interesting technology Mitch encountered was near Montevideo in Minnesota. Here, the Weed Zapper is used on weeds that rise above the crop canopy.

It uses an electric discharge that forces an electrical current through a plant’s stem. The current boils water inside the plant cells, bursting the cell walls. This instantly kills the plant, but the kill rate depends on the quality of the electrical contact.

“It works like a wick wiper to kill weeds using electricity from a generator unit mounted behind a tractor,” he says.

“The soil needs to be moist, which is a constraint for Australian farming systems.”

Weed Chipper

The University of Western Australia’s Associate Professor Andrew Guzzomi with the Weed Chipper, which is still progressing towards commercialisation. Photo: Anvil Media

An Australian development that drew high praise from Mitch was the Weed Chipper, a GRDC investment, which has yet to find a commercial partner.

The prototype uses optical weed detection technology to ‘see’ and then mechanically ‘chip’ weeds out of fallowed soil.

In tests, researchers found 100 per cent control of all weed species tested at all growth stages at three locations.

“The Weed Chipper would have a big role to play in fallow situations if a commercial unit was available,” he says. “If they could sell me one now, I’d be pretty interested.

“Instead of using our Weed-It, we could use the Weed Chipper to take the pressure off paraquat and mechanically control fleabane and other summer and autumn weeds in our fallows.”

Associate Professor Andrew Guzzomi, the director of the Centre for Engineering Innovation at UWA, says the Weed Chipper is still progressing towards commercialisation.

Future availability

Although most of these innovations are yet to become commercially available in Australia, Mitch sees the Weed Seed Destroyer and Weed Chipper as potentially playing an important role on Australian grain farms in the future.

“Both could mop-up weeds that escape herbicide application,” he says. “I see the potential for the Weed Chipper to be run autonomously on fallows over summer or pre-seeding.”

While Mitch’s study reiterated that there was no ‘silver bullet’ in weed management, he is hopeful some of the technologies will one day become available.

“The Weed Seed Destroyer and Weed Chipper have merit because many growers now have to deal with glyphosate resistance,” he says. “As new technologies are released, we must continue to use what is practical to deploy as part of our integrated approach to managing weeds.”

Study worthwhile

To those considering applying for a Nuffield Scholarship, Mitch says, “just do it”.

“Make the time because the people you meet, the knowledge you gain and the doors it opens are valuable.

“Even if you’ve had a university education, the Nuffield Scholarship gives you another network of people from whom you can learn. It is truly a mind-opening experience.”

More information: Mitch Henderson, [email protected]; Michael Walsh, [email protected]; Andrew Guzzomi, [email protected]

*UWA Associate Professor Michael Walsh will speak about the Weed Seed Destroyer, among other weed management systems, at the 2024 GRDC Updates in Perth, Wagga Wagga, Corowa, Dubbo and Goondiwindi. grdc.com.au/events/list