Key points

- Extreme wet weather conditions have led to a lot of bogged machinery on farms

- Three growers have lost their lives in the past 12 months trying to recover bogged machines

- Growers gathered at Grenfell, New South Wales, to share experiences on the safe recovery of bogged vehicles

- Safe recovery starts with a plan shared with your team

- Use only correctly rated recovery gear

- Be patient and work methodically

- Call for support if it is proving too difficult

A bogged tractor and seeder on Jamie Wright’s Greenethorpe, New South Wales, farm. Photo: Jamie Wright

In the wake of one of the wettest and most-expensive growing seasons in living memory, two New South Wales grain growers had an idea: a workshop on the safe recovery of bogged farm machinery.

Jamie Wright from Greenethorpe and Harvey Matthews from Piney Range discussed the idea with Delta Agribusiness’s Lachlan Fertilizers branch manager Anthony Dickson.

Their motivations were the forecast for more wet weather and keeping people safe.

Fresh in their minds was 33-year-old grower James Gibson, who tragically sustained fatal head injuries while extracting a bogged bulldozer near Monteagle, north of Young, in June.

Mr Gibson had been helping his neighbour with the extraction when a strap failed and a steel D-shackle was propelled through the glass door of the bulldozer. There was no dampener on the strap.

Mr Wright thought 40 people might turn up to the workshop and was “blown away” when 580 growers gathered at the Grenfell Showgrounds.

He introduced the workshop as being about gathering tips on how to use the right equipment to make vehicle recovery safe and efficient.

Also involved in the event were SafeWork NSW, Delta Ag, NSW Farmers, Carruthers Machinery Co, Hutcheon & Pearce and South West Tractors, and tow-truck operator South West Tilt Trays.

Engineer’s insights

Kondinin Group research engineer Ben White. Photo: Josh Giumelli

At the event, Mr Wright relayed some key points provided by Kondinin Group research engineer Ben White:

- Avoid wet areas – Do not try to harvest every hectare if you find a patch of wet ground. There will be several hectares to come back and harvest when conditions are drier.

- Lighten loads – Try to operate machinery with less grain on board. Empty harvester grain tanks and chaser bins earlier and more regularly. If trucks are in the paddock, avoid filling them. If you do become bogged, offload what grain you can.

- Remove the front – Removing the front will also lighten the load, enabling the front to be recovered later.

- Keep trucks out of paddocks – Aim to keep trucks out of paddocks, if possible. Use a chaser bin to load trucks parked on the hard ground around sheds or on internal roads.

- Reverse drive tyres – Before trafficking a paddock, it might be worth reversing one or both tyres on duals. This means swapping the tyres from the left to the right side and the tyres on the right to the left side of the machine. If you become bogged, reversing the tyres gives you more traction in reverse when another vehicle hooks up and pulls the vehicle out.

Reversing the tyres on your harvester can provide extra traction in reverse if the machine becomes bogged. Photo: Nicole Baxter

- Reduce tyre pressure – Reduce the pressure in the bogged vehicle’s tyres to the lowest in the manufacturer’s recommended range. Keep in mind that tyre pressure needs to be increased again for road travel.

- Use a shovel – Remove mud from around the tyres.

- Go steady – After putting some tension on the recovery strap, drive steadily, at between two and five kilometres an hour, depending on what is recommended by the strap or strop manufacturer.

- Pre-fit wire cables – Preparation is necessary to save time during a wet harvest. Pre-fitting galvanised wire cables underneath the harvester, or chaser bin, offers a quick way to retrieve equipment if it becomes bogged.

GrainGrowers with House Paddock Consulting and Kondinin Group research engineers Ben White and Josh Giumelli have produced a safety video on using recovery straps and retrieving bogged vehicles.

Assess the situation

NSW Farmers farm safety adviser Charles Laverty. Photo: Nicole Baxter

Charles Laverty from the NSW Farmers Farm Safety Advisory Program said it was important always to take a minute or two to fully assess the situation if you become bogged, because it may be different to the previous time.

“Check the condition of the recovery equipment every time you use it,” he said. “Always keep bystanders at least two-and-a-half times the length of the recovery straps away from – and to the side – of the recovery. Never stand next to it.

“When using cables, consider using pulleys for mechanical advantage, and when joining straps, avoid using steel shackles – they become projectiles if something breaks.”

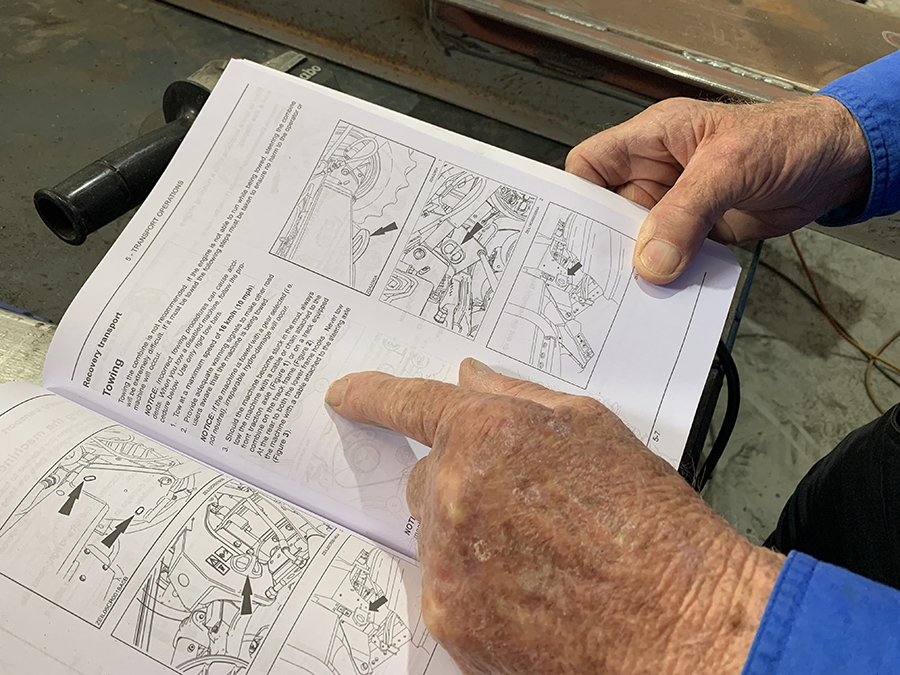

An important point raised by machinery dealers was to check the operators’ manual of the bogged vehicle. This will generally indicate where on the harvester or tractor to attach recovery straps to avoid damaging the machine.

Check the operators’ manuals for where to connect tow straps. Photo: Nicole Baxter

SafeWork NSW assistant state inspector Rhys Dive said what happened in June on a farm in Monteagle was not unique. “There’s been three fatalities – all men in their 30s attempting to recover bogged machinery,” he said.

“One was where a young man was trying to recover a bogged truck, and they were using chains hooked to the towbar. The chain failed and struck the man, causing fatal injuries.

“Another fatality occurred where two tractors were stuck in mud, and they were using chains. The chains broke and killed a person.”

Mr Dive echoed the need to refer to the operator’s manual before extricating a bogged vehicle.

“Always hang on to the operator’s manual because it should indicate the right method and gear to use, as well as showing where the recovery strap needs to be connected,” he said.

SafeWork NSW assistant state inspector Rhys Dive with Greenethorpe, NSW, grain grower Jamie Wright. Always check the condition of your recovery straps. Photo: Nicole Baxter

“If you are using the correct gear for the machinery you are trying to recover, and you use a dampener, most of the time you should be able to pull out of a bog safely.”

While forecast wet weather and the desire to harvest the crop before it is damaged by rain adds pressure at harvest time, Mr Dive said it was important to create a plan for the safest way to extract a bogged vehicle.

To reduce the risk to workers and others involved in vehicle and farm equipment recovery, he said to:

- assess the work environment and conditions before starting work

- avoid using vehicles and equipment if there is a likelihood of becoming bogged

- postpone work until conditions improve;

- create an exclusion zone around the equipment during the recovery activity

- only the vehicle operator and those necessary in the recovery should be allowed inside the exclusion zone

- ensure an effective communication method is established between them (voice, radio, hand signals);

Create an exclusion zone around the equipment during the recovery activity. Photo: Jamie Wright

- ensure anybody within the exclusion zone stands at 90 degrees to the axis of the tow line

- do not stand at either end of the tow line as you are at higher risk of injury if the tow line breaks;

- only use straps and attachments that are correctly rated for the weight and type of work involved;

- use a recovery dampener to reduce the force of recoil and risk of injury if the recovery line breaks;

- only use anchor points on vehicles approved by the manufacturer and listed in the operator’s manual;

- abort the extraction of the equipment if things are not going to plan;

- choose plant with laminated glass and external structural protection where available

- consult the original equipment manufacturers for tougher glass options and operator cabin protection in mobile plant;

- only use well-maintained and approved equipment in line with the manufacturer’s instructions;

- perform a risk assessment before attempting any equipment recovery; and

- ensure you have an emergency procedure plan in place.

Supplier tips

Mr Wright passed on some comments from Unilift Equipment’s Caleb Scott, who said to:

- use a dampener because if either the strap or shackle fails, the strap is more likely to fall to the ground and not slingshot towards the towing vehicle. A dampener could include a car tyre, blanket or car mat;

- avoid using chains or steel D-shackles because these can easily become projectiles. An alternative is a soft shackle rated correctly for the size of the vehicle;

An example of a soft shackle rated for machinery up to 75 tonnes. Photo: Jamie Wright

- check the effective life of your strap or strop. Ensure the gear is used according to the manufacturer’s directions;

- check the condition of all straps, strops, and shackles before you start work each season. Look for cracks, tears, or rust;

- Black Snake strops are available in nylon or Kevlar®. Nylon has 40 per cent stretch, Kevlar® has four per cent stretch;

- for a 10-tonne vehicle, use a 15t strap. If using a 15t strap, use a 17t D-shackle. The D-shackle needs to be bigger than the strap because if there is a weak point you want it to be the strap, not the steel D-shackle; and

- if using a soft shackle (made from Dyneema® rope), use one rated slightly lower than the strap. For example, if the strap is 15t rated, use a 12t soft shackle.

Paramedic’s advice

Grenfell-based NSW Ambulance station manager and paramedic Andrew Noble, who attended James Gibson’s accident, said it was highly likely that most people would bog farm equipment this season.

“Before I became a paramedic, I worked as a contract harvester, and I know time is money,” he said. “But rushing to extract equipment and not thinking about how you’re doing it could cause injury or damage to your machinery, which will cost you time and money also.

“If I see a wet patch coming up as I’m harvesting, I’ll stop, exit the machine, walk into it and think about whether I want to drive through it,” he said.

Grenfell-based NSW Ambulance station manager and paramedic Andrew Noble. Photo: Nicole Baxter

“Spending two minutes walking around the wet patch and thinking through your actions before rushing in without a plan could save you hours when pulling out a bogged machine.”

While Mr Noble said there were many good things about being a paramedic, one of the worst was having to tell somebody their loved one had passed away.

“When there is an accident on your farm, and you’re not at the house, finding you on your farm can be difficult,” he said.

“But everybody has a smartphone, so download the Emergency Plus app.

“When you open that app, it will give you a GPS location. When you call 000 in an emergency, you can give the operator your GPS location so we can find you.”

Strap sizes

Mr Wright pointed people to the Central Wheatbelt Imports website, where grower turned retailer Craig Gorfin had published a table based on his experience regarding the size of straps needed according to the power of the towing machine.

Mr Gorfin said all straps have limitations, and the correct-sized strap and load rating must be used to suit the available towing power (see Table 1).

Table 1: Craig Gorfin’s rough rule of thumb for the snatch strap size needed to suit the available towing power

Strap (kilograms) | Horsepower (up to) | Kilowatts (up to) |

16,000 | 135 (towing wheeled) | 100 |

26,000 | 220 (towing wheeled) | 164 |

50,000 | 330 (towing wheeled) | 246 |

60,000 | 380 (towing wheeled) | 283 |

75,000 | 480 (towing wheeled) | 358 |

100,000 | 550 (tracked) 600 (towing wheeled) | 410 |

150,000 | 700 (towing and tracked)* | 522 |

Note: Snatch straps are manufactured to let go at the weakest link at the end of the stitching loop. Straps that snap anywhere else or are torn have been damaged by misadventure or improper use.

*Applies if two tractors are hooked onto the bogged vehicle. Ensure you discuss your specific applications with the supplier when you buy recovery gear.

Source: Central Wheatbelt Imports.

More information: Jamie Wright, jamieandalisha@bigpond.com; Tom Matthews

Harvester modification

New South Wales grain grower Tom Matthews from Piney Range has pre-fitted galvanised wire rope that extends from heavy-duty 24.5-millimetre (one inch) plates bolted into the original tie-down points in the front axle of his Case IH harvester. The plates drop down far enough so that when tension is applied to the 25mm wire rope, they do not hit the undercarriage of the harvester. He has used 4.5 metres of galvanised wire rope. Two steel D-shackles attach the wire rope to the plates. The two wire ropes run back to a central point where they are hitched to the towbar when not used. Photo: Nicole Baxter

If the harvester becomes bogged, the galvanised wire rope, joined in a single eyelet, can be quickly unhitched and fitted to a tow strap using a soft shackle. This provides a safer alternative than shackling the recovery strap to the steering drawbar and prevents possible damage to the harvester. Photo: Nicole Baxter

Safety ideas

Greenethorpe, NSW, grain grower Jamie Wright uses a car tyre as a dampener. He threads the recovery strap through the car tyre to weigh it down should the recovery strap or shackles fail. The downward force of the car tyre dampens the recoil. Photo: Nicole Baxter

The end of Jamie Wright’s soft shackle is attached to the tractor via two galvanised wire ropes suspended under the chaser bin. A benefit of this set-up is that should the recovery strap or any shackles fail, they are likely to hit the chaser bin rather than the tractor’s window. Jamie has had no breakages since using this setup. However, he does plan to upgrade to thicker galvanised wire rope. Photo: Nicole Baxter

New Holland harvester recovery

There was plenty of interest in the display and advice offered by South West Tractors branch manager Joel De-Britt (front right) and Agricultural Equipment Holdings Group combine specialist Rick Barnett at the Grenfell Showgrounds. Photo: Nicole Baxter

At the Grenfell, NSW, safe recovery of bogged vehicles workshop, South West Tractors branch manager Joel De-Britt said there was an effective, simple and proven way to recover New Holland harvesters stuck in mud.

He said this comprised two 60-tonne snatch straps (see photo) in a bridle configuration, joined with a soft shackle. Another snatch strap (80t) is attached to the soft shackle and the towing vehicle.

“It’s important to join the shackles on tie-down points at the rear of the machine’s chassis and not the back steering axle of a harvester,” he said.

“On the front of the machine, there are two tie-down points on the bottom of the front axle.”

More information: Joel De-Britt,

One of the two points on the chassis on the rear of the machine where recovery straps can be attached to New Holland harvesters. Photo: Nicole Baxter

Contractor’s tips on retrieving bogged harvesters

Harvesting contractor Rod Gribble of Yenda, New South Wales, advises growers to take it slowly when removing bogged machinery. Photo: Rod Gribble

By Sophie Clayton

Harvesting contractor Rod Gribble of Yenda, New South Wales, says one potentially fatal risk of harvesting in wet conditions is retrieving bogged harvesters.

“We previously used chains or cables to pull out bogged headers,” Mr Gribble says.

“I had the chain break once, and it hurtled back at me. It hit the back of the tractor and was only a metre away from breaking the window and taking me out.”

He now uses snatch straps to pull out equipment as they have more give in them and are less likely to break and do damage – but caution is still required.

Patience needed

Mr Gribble says people needed to be patient.

“Someone will get bogged, and when you do, just stop.”

“Remember that a header might weigh 25 to 30 tonnes, but you’re probably going to bog it when it’s got a fully loaded grain tank.

“The effort to pull out a loaded header is much greater – as they are a dead weight stuck in the ground.

“Unload the grain first, take your time and clear the mud away from all the tyres with a shovel or excavator.”

Mr Gribble says growers should also review the operator’s manual for their machinery and learn the specific guidance for retrieving equipment should it get bogged.

Advice may vary and knowing the safest way to deal with specific equipment in advance – such as the recommended attachment points for snatch straps – is essential.

After clearing away the mud, Mr Gribble advises taking things slowly.

“Don’t tear off at 15 kilometres per hour; just take it slow and steady – even snatch straps can break and D-shackles can go flying.

“You’ve also got to be aware of the strap and D shackles’ rating when pulling out gear.

“People have died from trying to retrieve bogged equipment. You can get a new header, you can’t get a new head.

“Know when to walk away.”

Reach out for support

There are many challenges associated with recovering bogged gear.

At stressful times, remember to check in on others.

If you need support:

- For emergencies: call triple zero (000)

- Suicide Call Back Service:

1300 659 467 - Lifeline: 13 11 14

- Beyond Blue:

1300 224 636 - MensLine Australia:

1300 78 99 78 - Ifarmwell

- Healthdirect

- Are you bogged mate?