Key points

- Gypsum is the best tool for suppressing dispersion (short term) and replacing sodium with calcium (long term) in dispersive soils. Multiple applications over many years are needed to change soil chemistry

- Yield improvements from gypsum are seasonal, with increases more likely in dry years and no change in normal or wet years where there is no waterlogging

- Water harvesting using mounds and polymer ‘hats’ has increased yield by 35 per cent on average in proof-of-concept work

- Mineral mulches have shown an average yield increase of 37 per cent on saline-sodic soils from reduced soil evaporation

- Deep tillage, even with amendments (gypsum, straw, organic matter) is not increasing yield in lower-rainfall regions

Dispersive soils present a multitude of issues – poor permeability, high soil strength, surface crusting, waterlogging, alkaline pH, salinity and boron toxicity.

In low-rainfall areas, salt accumulation and high evaporation risk are additional issues. Limited pore space and low rainfall mean more water is stored closer to the surface and is therefore more prone to evaporation.

In these environments, salt has accumulated over the eons from rainfall and aeolian deposition. When managing these soils, the aim is to get enough water into the soil profile to leach transient salinity deeper into the soil profile and, in doing so, increase the plant-available water.

For decades, gypsum has been the ‘go-to’ treatment to improve soil structure and soil water-holding capacity on dispersive soils. Through short and long-term mechanisms (the salt effect and displacing sodium with calcium, respectively), gypsum helps improve soil structure and, consequently, soil water-holding capacity and root growth.

Improvements using gypsum can take a long time. In recent years, researchers have been looking at other treatment options to improve crop growth on dispersive soils. Since 2019, David Hall has led a Western Australian Department of Primary Industries and Regional Development (DPIRD) project supported by GRDC to investigate novel options suited to dispersive clays in low-rainfall areas of the WA eastern wheatbelt.

Testing alternatives

Mineral mulches

Mulching the soil:

- protects the surface by absorbing raindrop impact that can cause hard setting and crusting;

- reduces soil water evaporation; and

- reduces capillary rise of salt to the surface in salt-affected soils.

While mulches are traditionally organic materials such as straw or woodchips, mineral mulches (sand and gravel) can offer many of the same benefits.

In trials at Ravensthorpe, WA, four to six centimetres of gravel mulch increased grain yields from 0.5 to 1.8 tonnes per hectare, averaging 0.77t/ha or 37 per cent over three years. Yields increased in eight out of the 11 trials.

The yield increases are attributed to reduced soil water evaporation. The remaining three trials showed no difference between the control and mulched sites. Those that did not respond tended to have better-structured soil and were less saline in higher-rainfall years.

Glasshouse experiments to quantify how much mineral mulches reduce evaporation found that sand was more effective than gravel, and the thicker the mulch, the more water stayed in the soil. Compared to the control, 2cm of gravel reduced evaporation by 62 millimetres, and 8cm of gravel reduced evaporation by 82mm. In a separate experiment, 2cm of sand mulch kept an extra 75mm of water in the soil, and 8cm of sand kept an extra 115mm of water in the soil compared with the control.

While reducing evaporation could be a great asset in dry years, it could present a problem if the soil becomes waterlogged. During 2020 trials, canola plots with sand mulch had a stronger start but there were no yield differences between the control at the end of the season. The wet August in 2020 was thought to have played a role on the highly dispersive duplex soil. As the sand mulch reduced evaporation, the soil stayed waterlogged for longer than plots without mulch.

Practicalities

Rate-wise, a 2cm thick layer of sand equates to 280t/ha and 4cm equates to 560t/ha. Gravel spread at 2cm thickness is equivalent to 400t/ha, while 8cm is 1600t/ha. The mulches are surface spread by a carry grader or bulk spreader and are not incorporated.

Over time, the mulch sand will gravitate towards the seeding furrows and is more readily incorporated into the topsoils compared with the gravel. The longevity of the mineral mulch treatments is not fully known and is very important as it will affect the profitability of using them. Grower observations to date suggest yield benefits can last 10 years after mineral mulch is applied.

Mulching with sand or gravel is very expensive. If sand or gravel is already on-hand or nearby in the paddock, it costs about $1200/ha to spread. For growers needing to buy and spread mineral mulches, the costs might outweigh the benefits.

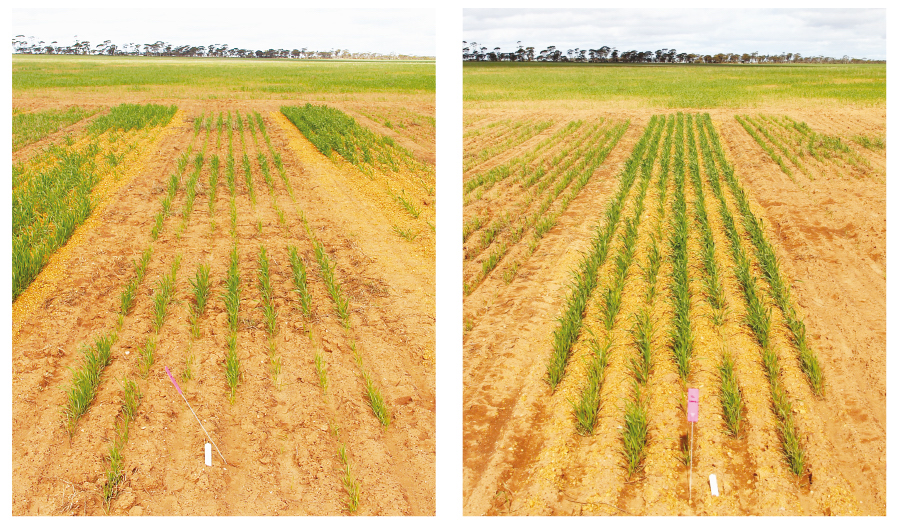

Figure 1: Control plot (left) and 2cm gravel mulch plot (right) on 11 August 2022, five months after sowing. Trial at Moorine Rock, WA. Photos: Glen Reithmuller, DPIRD

Mounds with and without hats

Mounding the soil between crop rows channels rainfall into the row. While mounding the soil between crop rows for better water harvesting is not a new idea, adding an impermeable layer on top of the mound is.

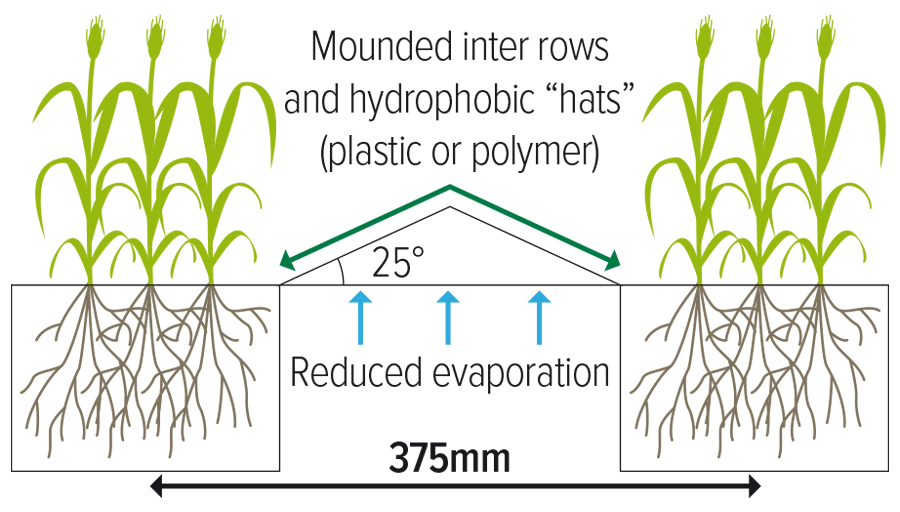

Two different materials were used as ‘hats’ for the mounds – clear plastic and two polymers. The polymers were sprayed on. The hats increased water harvesting from the furrow into the crop row and decreased evaporation from the sides of the mounds (Figure 2).

Adding plastic or polymer hats to the mounds gave an average 0.52t/ha (35 per cent) yield increase over 16 trial years. Overall, mounding without a hat made no difference.

Figure 2: Diagram of mounted inter-rows with plastic or polymer hats increased run-off into the root zone and reduce evaporation from between crop rows.

Practicalities

One of the polymers is a CSIRO-developed product that is biodegradable; the other is not biodegradable. The aim is for the polymer to last six months before breaking down. Researchers are concerned about microplastics and are working on solutions that do not leave any microplastics in the soil. Costs are still unclear, but with productivity increases worth about $150/ha, there is a clear price signal to potential manufacturers.

Deep tillage and amendments

Ripping responses on dispersive soil in the WA eastern wheatbelt are variable and can even result in a yield penalty, especially if more hostile soil is brought to the surface. Of the 11 ripping trials done in this project, none showed a yield increase.

Gypsum is the most common amendment applied to dispersive soils; however, research is gradually exploring various organic matter sources. In time, deep-placed organics and amendments can improve soil structure and stimulate root growth and, theoretically, increase yield. Research in New South Wales has had promising results, with deep-placed organic matter (manure and pea hay) increasing soil stability more than threefold.

Trials at Lake Grace in WA tested deep ripping and incorporating gypsum (2.5t/ha), composted chicken manure (8t/ha) or lucerne straw (12t/ha). After five years, there was a small average grain yield increase (0.17t/ha or 7 per cent), with yield penalties in some years. Lack of water at the end of the season was a likely limitation to a bigger yield increase.

In dry years, crops on the organic matter plots had additional early biomass production that did not convert into yield. The early growth used much of the stored water prior to grain fill. The promising results in the eastern states tend to be in high-rainfall regions or years.

Gypsum

Gypsum is usually broadcast and needs regular applications to permanently change soil chemistry. In the short term, applications of two to 3t/ha work by the ‘salt effect’ suppressing dispersion. This effect will dissipate after a few seasons, therefore regular applications are required to continue to suppress dispersion while gradually replacing exchangeable sodium with calcium. Highly sodic soils need more than 20t of gypsum/ha to permanently replace sodium with calcium and reduce exchangeable sodium percentage to acceptable levels.

The project trialled two approaches to gypsum:

- banding gypsum at rates up to 100kg/ha in the furrow each year; and

- the more-traditional broadcasting of gypsum once at rates more than 500kg/ha.

Yield responses were the same between the high (broadcast once) and low (furrow applied annually) rates. Gypsum improved yields during dry seasons, but during wet years (2021 and 2022) there was no significant difference to the control. In dry seasons, improvements in water infiltration led to improved yields.

By suppressing dispersion, gypsum makes it easier for rainfall (and soluble salts) to filter deeper into the soil. In low-rainfall years, any impediment to water infiltration will increase the chance of water being lost through evaporation. In high-rainfall years, there tends to be more water at depth.

Researchers are finding that, in wet years, as long as the soil is not waterlogged, there is enough plant-available water that gypsum has little impact.

On average across the trials, gypsum led to a 0.14t/ha or 6.5 per cent yield increase, with the biggest responses happening during dry years.

Conclusion

In lower-rainfall regions, gypsum is still a good option to improve dispersive soil and increase soil structure and water-holding capacity. Yield responses tend to be more noticeable in drier seasons.

There are still many aspects of mineral mulches and mound ‘hats’ to work out; however, early results are promising.

Deep tillage with amendments is not increasing yield.

Acknowledgements: David Hall, DPIRD

Further reading

Knights S, 2022. Exploring the science of mineral mulch. GroundCover Issue 157, March-April 2022.