Key points

- Sodic clay soils (heavy soils) in low-rainfall environments are especially prone to high soil evaporation rates due to poor water infiltration and low rainfall

- Field trials have shown that unincorporated gravel and sand mulches on clay soils can increase wheat yield by more than one tonne per hectare when waterlogging does not occur

- In a glasshouse trial, the addition of as little as two centimetres of gravel mulch has significantly reduced soil evaporation

- Waterlogging is exacerbated by mineral mulches

- Do not incorporate the sand or gravel – it is a surface mulch

With up to 40 per cent of rainfall lost to the atmosphere through soil evaporation instead of being transpired by crops and converted into grain, new methods to retain water in cropping systems are being researched.

Soil evaporation is exacerbated where soil properties reduce rainfall infiltration. This is the case in sodic clay soils in the eastern Western Australian wheatbelt, where poor structure, clay textures and low rainfall result in more water being stored near the surface where it is prone to surface evaporation.

Gypsum remains the best way to increase water infiltration in dispersive sodic clay soils. However, there is some new research showing the benefits of mulches.

Growers producing crops on heavy sodic clays in low-rainfall environments have often observed the benefits of organic mulches on crop establishment. This is commonly shown in header trails where the soil stays wetter for longer under the previous season’s harvested trash. However, there is also growing evidence that mineral mulches can also improve crop establishment and yields.

David Hall, a senior researcher at the Department of Primary Industries and Regional Development (DPIRD) based in Esperance, is working with growers around Ravensthorpe leading a GRDC-co-invested project to investigate the potential of mineral mulches to improve crop performance on these soils.

“Growers at Ravensthorpe have observed that mineral mulches – gravel and sand – can improve water retention and crop yields,” he says. “For example, the addition of a four-centimetre blanket of ironstone gravel by Peter Daw in two un-replicated strips has shown grain yield benefits of between 0.5 and 1.8 tonnes per hectare for cereals over two years compared to control crops on either side of the strips.”

These red alkaline loamy duplex soils are sodic but not highly dispersive.

Ravensthorpe grower Peter Daw with a gravel mulched strip showing better wheat growth compared to neighbouring control in July 2020. Photo: Sam Richards, DPIRD

Research effort

“We have often struggled to identify ways to improve sodic soils due to their poor structure impacting on plant-water relationships,” Mr Hall says.

Sodic clay soils have particular production challenges as they are often dispersive, so the clay can separate from the sand and then be washed through the soil and block pores.

“This results in poor water infiltration – increasing soil density – and salts can accumulate, causing transient salinity and toxic levels of sodium, chloride and boron at depth.

The solution is to consider any means that increases rainfall infiltration and storage into the soil.

The GRDC-DPIRD project is taking a multi-faceted approach to this, including:

- the potential of gravel mulch;

- water harvesting with mounds;

- in-furrow low-rate gypsum applications (research led by Dr Ed Barrett-Lennard, Perth and Rushna Munir, Merredin);

- tillage systems that disrupt but do not bring to the surface toxic subsoils (research led by Wayne Parker, Geraldton); and

- deep-placed organics (also led by Mr Hall).

More about mineral mulch

“We are working with growers to generate the scientific understanding to validate the mulching practice using both field and detailed glasshouse trials,” Mr Hall says.

A gravel pile on Peter Daw’s Ravensthorpe property. Peter says the gravel is also in high demand from local road builders. Photo: David Hall, DPIRD

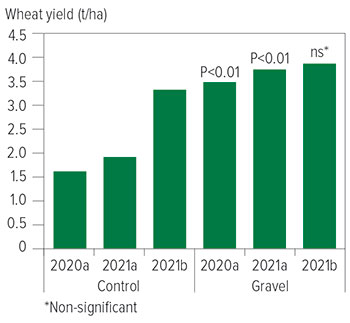

A preliminary trial on Mr Daw’s property monitored two gravel treatments over two years.

“Peter put out an initial strip ‘a’, which we monitored in 2020 and 2021, and then put out another strip ‘b’ in 2021. Strip ‘a’ was four metres wide by 30m long and the gravel was five centimetres thick. Strip ‘b’, which was in the same paddock, was 12m wide by 250m long and the gravel was four to seven centimetres thick. Both treatments had paired controls with no gravel,” Mr Hall says.

The 2020 season had a very dry start and was saved by good August rainfall, while the 2021 season had good rains throughout the season along with mild temperatures at the end of the season.

A simple paired statistical test was carried out on the wheat yields that showed significant increases for the wheat yield performance under gravel treatment ‘a’, with this mulched treatment achieving yield increases of up to 1.8t/ha (Figure 1).

Figure 1: Wheat yield performance under two gravel mulch treatments as compared to paired control treatments (Strip ‘a’, four metres wide by 30m long, gravel five centimetres thick. Strip ‘b’, 12m wide by 250m long, gravel was four to seven centimetres thick).

Source: DPIRD

“We are building on these preliminary trials with more-detailed field trials where we will measure soil properties, germination at different times, surface moisture at emergence, phenology, biomass and grain yield,” Mr Hall says.

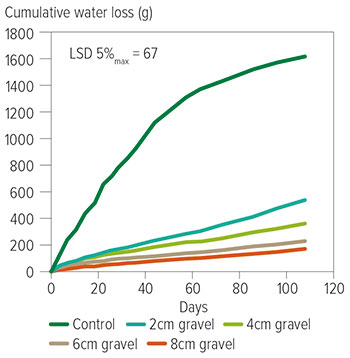

A replicated glasshouse trial, using gravel sourced from Mr Daw’s property, run over 107 days in 2021 has demonstrated the benefits of gravel in reducing soil evaporation. When compared to no gravel, two centimetres of gravel reduced evaporation from 1618 grams to 543 grams (Figure 2). This equates to 61 millimetres of water not lost through soil evaporation where gravel had been applied.

“The preliminary gravel mulch field trial results on Peter’s property contrast with those achieved under sand mulch, but we think this is influenced by the soil type,” Mr Hall says.

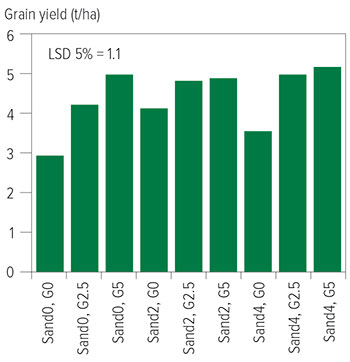

In this respect, a field trial has shown that the addition of two and four centimetres of sand to a highly dispersible grey alkaline loamy duplex at Lloyd Burrell’s property near Mount Madden has also shown promise but not in all years.

In the dry autumn of 2020, canola emerged earlier on the sanded treatments when measured in mid-May, with the differences in earlier development persisting through to flowering.

By the end of the season, plant numbers were similar between the control and sanded treatments and no differences in yield were found between the control and sanded treatments.

Figure 2: Cumulative water loss by evaporation for zero centimetres (G0), 2cm (G2), 4cm (G4), 6cm (G6) and 8cm (G8) gravel mulch sourced from Peter Daw’s property applied to pots in a glasshouse.

Source: DPIRD

Part of this lack of difference is thought to be due to additional waterlogging where the sand prevented evaporation during the wet 2020 August. In 2021, gypsum at rates of zero, 2.5 and 5t/ha were applied across the sanded treatments.

On average, the sanding and gypsum treatments in 2021 increased wheat yields by 0.5t/ha; however, on this soil type the 2.5 and 5t/ha gypsum treatments without sand increased wheat yields by 1.3 and 2t/ha compared to the control (Figure 2).

Consequently, for this soil type, gypsum could be the most-profitable amelioration strategy.

“This highlights the need to know about soil type and characteristics to select the most appropriate mulch or amelioration treatment,” Mr Hall says.

The economics of sand and gravel mulches will depend on the cost of the product, availability on-farm, transport and spreading.

The sand and gravel mulches used in the above experiments were obtained on-farm.

The rates used for the sand of two and four centimetres equate to 280 and 560t/ha. The sand was surface-spread and not incorporated.

Figure 3: Effect of sand spread at zero, two and four centimetres and gypsum spread at zero, 2.5 and 5t/ha on 2021 wheat yields at a field site at Lloyd Burrell’s property near Mt Madden.

Source: DPIRD

After two years, the sand had accumulated in the seeding furrows, with the different rates still visually distinctive.

Gravel spread at 2cm thickness is equivalent to 400t/ha, while 8cm is 1600t/ha. Visually, the gravel does not move in the field or become incorporated as much as the sand.

“The use of carry graders and sourcing on-farm materials such as clay has been widely practiced in WA.

"The key difference here is that the sand or gravel mulch is not incorporated but left on the surface to prevent water wicking from the clay and evaporating at the surface.

"Once incorporated, there will be little or no benefit from the mineral mulch,” Mr Hall says.

More information: David Hall, 0447 914 013, david.hall@dpird.wa.gov.au