Exciting barley yield responses in a sodic soil trial in Western Australia’s low-rainfall eastern wheatbelt region are changing the way researchers and growers think about gypsum applications.

Gypsum has often been considered in the same way as lime used to be – with blanket amounts spread across paddocks in an attempt to alleviate sodic dispersive soils.

Challenging this way of thinking, this trial in the eastern wheatbelt is considering the impact of small amounts of gypsum placed under the seed (with the fertiliser) at sowing time.

What this new approach is demonstrating, according to Department of Primary Industries and Regional Development (DPIRD) principal soil scientist Ed Barrett-Lennard, is the role of gypsum in expanding the “bucket” under the germinating seed, allowing for improved root access to water and nutrients.

While the blanket application of gypsum has proven to be profitable in numerous trials over the past few years, he says, this new precision approach could provide better financial returns in these challenging soils.

Understanding the science of the soil

Dr Barrett-Lennard says the trial was born out of a deeper understanding of the way sodic soils function and the impact of transient salinity in these soil types.

Transient salinity comes from a range of sources, including rain and dust, as opposed to salinity from rising water tables. It builds up over time in dispersive soils.

Dispersive soils, or unstable soils, contain clay particles which clog the soil pores, reducing the rate of water infiltration and drainage.

Gypsum works to “unplug” the soil and assists in moving water, salinity and nutrients through the soil profile.

The trial

This trial in Merredin is considering the twofold value of both precision gypsum placement plus the crop response to strategic water harvesting methods – with plastic sheeting, as a proof of concept, manually applied to the mounds, which directs all moisture into the furrows.

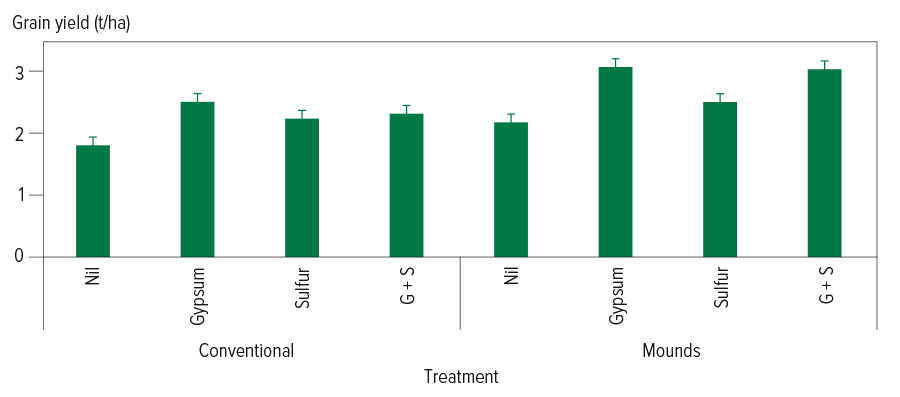

Dr Barrett-Lennard says the combination of the mounding, plastic sheeting and the precision gypsum application saw a yield increase of 70 per cent when compared to the control (conventional seeding, no plastic coverings and no gypsum applied).

Yield increases of 28 per cent occurred by simply adding gypsum to the planting process of a conventionally sown treatment.

A very low rate of gypsum application (50 kilograms per hectare) was placed in the furrow during planting as part of the fertiliser application. This can be compared to more traditional rates of five to 10 tonnes/ha spread as a blanket across the paddock.

Growing season (February to October) rainfall of 215mm was received at the Merredin trial site, highlighting the value of the plastic sheeting over the mounds as a water harvesting strategy.

Elemental sulfur was applied separately, and also together with the gypsum, to determine whether solving the alkalinity of the soil had an impact on yields.

While the elemental sulfur did see some yield improvements when applied on its own, it was the combination of the gypsum and plastic-coated mounds that saw the biggest yield response.

Barley from the conventionally sown (no mounds, no gypsum and no sulfur) treatment achieved a grain yield of 1.81t/ha, compared to 3.08t/ha on the treatment with mounds, plastic sheeting and applied gypsum – an increase of 1.27t/ha or 70 per cent.

Figure 1 Yield results from the trial at Merredin. Source: DPIRD

“What we believe we are seeing in these trials is a brief electrolyte effect from the gypsum – meaning the gypsum is opening up the soil path under the seed, using the extra moisture collected from the mounds and furrows to flush out the salinity, allowing for good root establishment in the early growth stage,” Dr Barrett-Lennard says.

“We also believe the gypsum activity in the soil is short-term because the gypsum is flushed out along with the transient salinity – meaning under this precision strategy, gypsum would need to be applied every year at seeding time.”

Despite the need to increase the frequency of these applications, such a significant reduction in per-hectare application rates could see major savings for growers, according to Dr Barrett-Lennard.

In fact, at rates of just 50kg/ha, these results can be achieved for just a few dollars per hectare.

Water harvesting proof of concept

Dr Barrett-Lennard acknowledges that manually applied plastic coating on the furrows is a proof of concept only and currently is not commercially viable across broadacre properties.

Together with the team at DPIRD, including Dana Mulvany, Laine Williamson and Glen Riethmuller, and overseen by project manager David Hall, Dr Barrett-Lennard laid the plastic over the mound, using pegs to keep it in place.

However, he says, in future there may be opportunities to apply this knowledge using new technologies and across large land areas.

“This trial has demonstrated what is possible if we can develop the technology to apply these types of concepts at the broadacre scale,” Dr Barrett-Lennard says.

The combination approach

By combining a water harvesting strategy with the electrolyte effect of gypsum, Dr Barrett-Lennard says plants can have access to all available water at critical growth stages.

“If we do not have a lot of available water – particularly during that early germination period – we do not want that water to move right through the profile. We only want it to move just a bit deeper, giving the roots access to a bucket of moisture during the growing season, which is a major change in how we think about gypsum,” he says.

“If we over-apply gypsum, it might leach out all the salt stored in the soil, but it might also leach out the small amounts of moisture available in the soil – which is exactly what we do not want to do.

“Through this precision placement method, we are attempting to create the right bucket size for each plant to give it the best chance at all times through the season.”

This trial has demonstrated what is possible if we can develop the technology to apply these types of concepts at the broadacre scale.

How to diagnose sodic soils

Dispersive sodic soils have poor infiltration and often water will pool on the surface after a rainfall event.

These soils may also display small calcium carbonate rocks on the surface or at depths to 50cm in the soil profile; these are a sign of alkalinity. In an electromagnetic (EM) survey, high signals will be seen in patches across the paddocks.

In drier years, Dr Barrett-Lennard says, the crops will be of variable height.

The future

With only one year of results so far from this Merredin research, Dr Barrett-Lennard says it will be a trial-and-error approach for growers with these very specific, heavy-textured sodic soils over the coming few years.

For next year’s seeding program, some growers may consider the precision placement of gypsum combined with normal fertiliser applications.

“We are hoping to work closely with growers in these specific regions to see these results translated in the paddock,” Dr Barrett-Lennard says.

“Ultimately, if we continue to see yield responses such as these seen in this Merredin trial, we would hope fertiliser companies might consider the development of fertiliser products more specific to these sodic soil regions.”

More information: Dealing with dispersive soils fact sheet.