With a wealth of experience working in the aviation industry, Scott Mackie from South East Air Ag in Esperance, WA, was well-placed to speak about achieving the best crop management outcomes possible at the recent GRDC webinar on aerial spray application.

Mr Mackie, who has 42 years’ experience in the aviation industry – 38 of those years in aerial agriculture – provided an overview on how to engage and work with aerial operators.

Unlike the ‘crop dusters’ of the 1930s, the industry today views itself as aerial applicators of crop management products. The operators are all commercial pilots and CASA licensed, with an aerial application rating that allows them to operate in the low-level agricultural environment.

Mr Mackie listed many advantages of aerial applications, including:

- quicker application;

- it is the only mode available to some growers in wet years;

- covers large areas rapidly;

- eliminates mechanical damage to crops;

- eliminates soil compaction;

- avoids disease transfer;

- can treat tall crops; and

- the downdraft turbulence from the aircraft can enhance product penetration.

To achieve these benefits, however, means operating in ways that manage the potential for harm in the form of:

- off-target damage;

- label restrictions on aerial application;

- drift from inversion;

- restrictions from common hazards;

- noise, sensitive areas and neighbours;

- adverse weather events; and

- airstrip access in wet conditions.

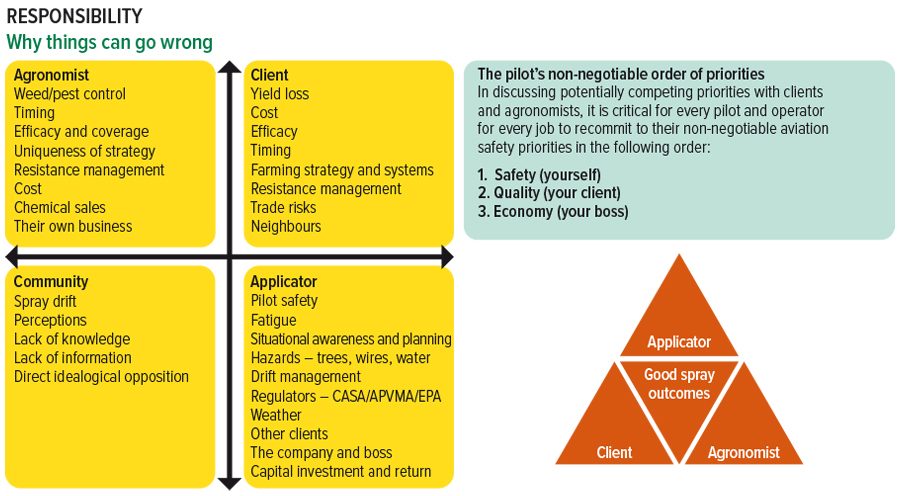

The nature of the competing priorities from agronomists, clients, applicators and the community are shown in Figure 1. From a grower’s perspective, communication with the operator is key to obtaining the best possible results. This centres on defining the spray parameters, which includes ensuring a product is registered for aerial application and the operating environment on-farm for the aircraft.

Figure 1: Aerial operators operating practices manage the competing priorities of growers, agronomists, operators and communities.

Source: Scott Mackie, South East Air Ag

Mr Mackie said that maps that clearly identified the target paddock, the product and the application rate were essential. Outcomes could be further boosted by also highlighting the location of susceptible crops, neighbouring properties and any hazards, such as powerlines, houses, creeks, dams, towers, beehives, the school bus route and windmills.

He pointed out that apps such as Agworld were available to assist in producing maps.

“The more information provided to the pilot, the better the spray outcome,” he said. “Operators provide an Aerial Application Order form on their websites. All the relevant questions are there to help pre-plan the job. The form can vary between operators, and some allow for downloading information onto a map.”

He added that providing a suitable working space for the operator was an asset that could earn the grower priority service provision and reduce costs. The ideal workspace includes:

- a runway that is 1000 metres long;

- 10m hard, smooth surface down the centre of the strip, with 10m clear on either side;

- a strip that is relatively smooth with no humps or bumps, although it can be moderately undulating; and

- ideally, a downhill strip and into the wind.

As to costs, Mr Mackie said that operators were generally looking for a certain hourly return for their aircraft. “As a rule of thumb, expect to pay around $15 per hectare for broadacre work. And upwards of $35/ha for a small field in hilly terrain. However, large jobs tend to attract a discount.”

To get the full benefits of aerial application, Mr Mackie explained that operators deployed technology that tested and optimised the spray settings before applying a product.

“From this data, we can see where coverage is high or low and adjust nozzle placement to even up the spray pattern or correct the placement of the pump or bent boom hangers,” he said.

Growers take to the skies

The operation of aircraft, spray drones and a new option – on-farm automated drone docking stations – were covered in a recent GRDC webinar.

A better understanding of aerial applications has been raised at several National Grower Network meetings.

More information: To view the webinar, go to GRDC past online events.

Read also: The future is here – automated drone docks coming to a farm near you and Wet years a potential challenge for global market requirements.

A range of support materials on aerial application are available to agronomists and clients from the Aerial Agricultural Association of Australia (AAAA) website, including the ‘Agronomists’ Guide to Aerial Application’ which can be downloaded for free as an E-Book.