Applying fungicides to protect crops against disease is critical to optimise yield and profitability, particularly when there is limited genetic resistance. Typically, fungicides are sprayed at key growth stages on a calendar basis or when the weather is conducive for disease.

None of these methods usually account for whether there is actually a pathogen present. This can result in suboptimal timing, rendering a spray inefficient or, sometimes, completely ineffective.

The best time to apply a fungicide is generally as soon as spores blow on to the property (for protectants), or during early infection stages (for curatives).

However, this level of precision requires knowing when spores of disease-causing fungi are present. Until now, that has proven nearly impossible for commercial operations.

At BioScout, a GRDC investment through the GrainInnovate fund has made it possible to explore opportunities to automate the detection process.

The SporeScout can operate autonomously, requiring servicing just once a year. Photo: BioScout

This investment has resulted in the development of SporeScout, an automated spore trapping unit that provides data on disease threats on-farm in almost real-time.

This technology platform uses automated microscopy and machine learning to support decision-making and optimise disease management.

How it works

The BioScout SporeScout is a compact, autonomous spore trap and weather station designed for continuous monitoring in broadacre crops, vineyards, orchards and anywhere microscopic airborne threats are found.

It is designed to be ‘set-and-forget’ with servicing required only about once a year, which is performed by BioScout (see Figure 1).

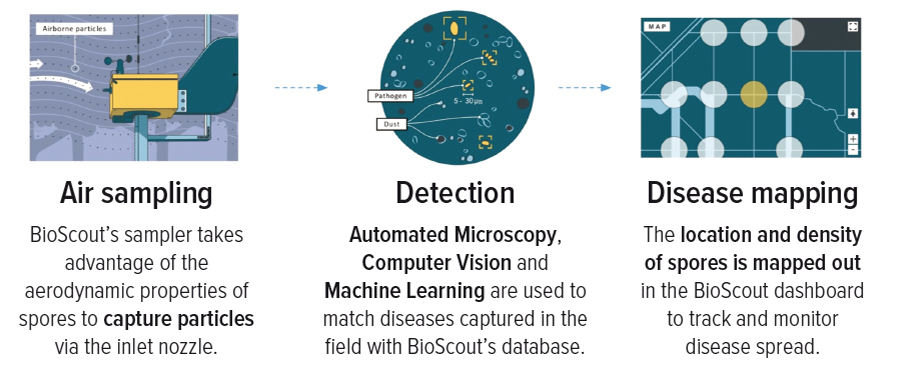

Figure 1: How the SporeScout works.

Source: BioScout

The SporeScout is placed on a mount that is secured by a ground screw that burrows 1.3 metres into the soil. It is connected to a solar panel that provides power to the unit and is on a slip ring with a wind sail, allowing it to rotate 360 degrees and always face into the wind.

To sample spores, the SporeScout draws in air using a low-power fan connected to a flow-rate sensor to maintain a constant rate of 10 litres per minute. This is important later in the process for calculating airborne spore concentrations.

This air then passes through a specialised impaction nozzle, capturing a sample of airborne spores and other particles on a transparent adhesive tape.

Airborne spores are captured on transparent adhesive tape and imaged using a high-resolution microscope attached to a camera. Photo: BioScout

After the sampling, the fan stops and the sample tape moves in front of a high-resolution microscope attached to a camera. This camera is equipped with LED illumination and is mounted on a small robot that moves it across the sample tape, capturing 220 high-resolution images of the entire sample.

The SporeScout uploads the images to BioScout’s cloud-based systems. The unit requires a minimum of two bars of Telstra 4G for this process and uploads data in small packets when connectivity is present.

Once the imagery is stored in the servers, the machine learning algorithms kick in.

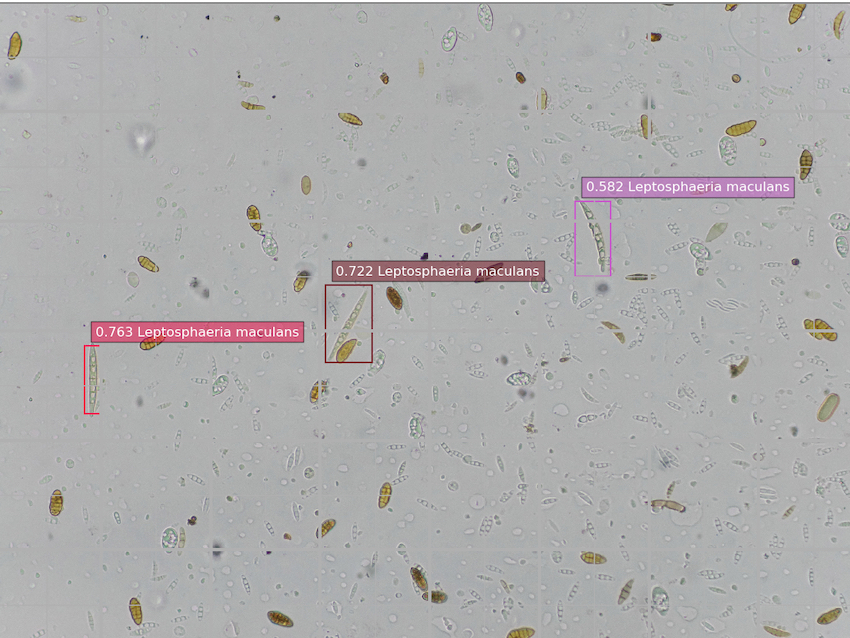

BioScout enables computers to act as plant pathologists by training machine learning (ML) algorithms to identify spores of disease-causing fungi.

Once an ML algorithm has completed its training and reaches a high degree of accuracy, it can comb through a sample tape very quickly. BioScout develops many different ML algorithms to look for different spore types and can run multiple ML models in parallel through hundreds of sample tapes in less than a second.

This processing power means that the difference between scanning for one disease on one farm and 15 diseases on 300 farms is a matter of seconds. This is scalable technology and can theoretically be applied to any airborne particulate above two microns.

Once the spores of each disease are identified, the recorded volume of air is used to provide an airborne spore concentration and plot it on a graph in BioScout’s online dashboard (see Figure 2).

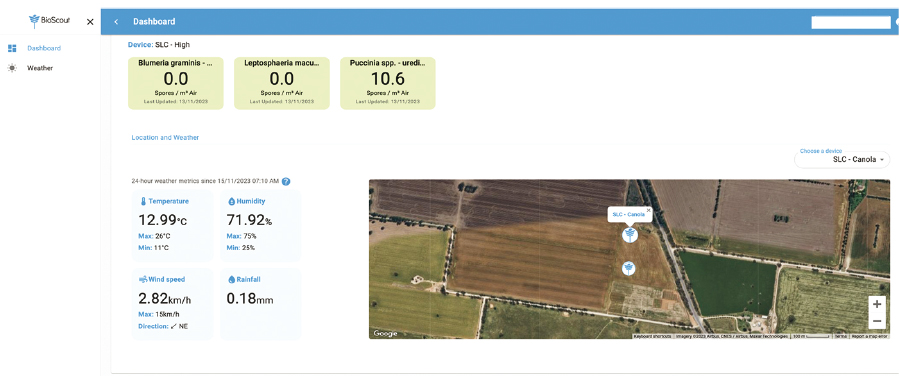

Figure 2: Data is visible within a dashboard that displays the concentration of detected pathogens alongside weather data.

Source: BioScout

Growers can see which spores of disease-causing fungi are present on-farm and look at trends in their amounts over time (see Figure 3). In combination with BioScout’s weather system, growers can also decide when conditions are conducive to infection and use this information to target disease management strategies.

Figure 3: The SporeScout dashboard can also track trends in pathogen levels over time.

Source: BioScout

Benefits to growers

Near real-time monitoring of pathogens offers several benefits. The main one is knowing which pathogens are present when deciding to spray. This informs which type of fungicide to use.

Growers can also evaluate the effectiveness of a disease management protocol since airborne spore loads from an infected crop should diminish following an effective fungicide application. If spore loads remain the same, growers have time to quickly troubleshoot before conditions worsen.

Lastly, growers can see the impact of diseases coming from last year’s stubble and gain confidence in their integrated disease management strategies.

Automated disease surveillance network

BioScout has launched Australia’s first automated disease surveillance network. The network is supported by an R&D investment from GRDC and will be powered by BioScout’s SporeScout spore traps. This network will be free for the industry to view for the next two years.

This national initiative will leverage technical support and expertise from pathologists at the Western Australian Department of Primary Industries and Regional Development (DPIRD), South Australian Research and Development Institute and New South Wales Department of Primary Industries. The initiative will also link with a related GRDC project by DataFarming that aims to provide useful information to agronomists and growers on fungicide management via satellite imagery.

This initiative will see a total of 60 samplers strategically placed across key growing regions, including some alongside National Variety Trial sites, continuously monitoring for airborne fungal pathogens. A Sentinel sampling unit that has the capability to genotype strains (iMapPESTS) will be co-located alongside a SporeScout unit in each growing region by state department pathologists.

The collected data will be aggregated and analysed to provide regional disease insights into what is in the air and where it is going. It will also provide a basis to link the spore-trapping data collected by SporeScout’s technology with disease modelling tools being developed in a national investment led by DPIRD. This is a collaboration involving researchers across Australia and commercial partners including Agworld and Back Paddock.

Growers and agronomists interested in gaining access to the automated spore surveillance network can sign up using the provided QR code.

Growers and agronomists interested in gaining access to the automated spore surveillance network are invited to sign up to BioScout.

More information: info@bioscout.com.au; BioScout