A national project is getting underway to more fully use the data and software capabilities of modern machinery and weed mapping technologies to better target weeds and their seedbanks. The project is backed by a $6 million GRDC investment.

Led by Dr Mike Ashworth at the Australian Herbicide Resistance Initiative (AHRI), the project aims to build into routine farm operations the ability to concurrently monitor and then strategically target weeds. The approach could ultimately reduce herbicide dependency, costs and the rate at which weeds acquire resistance.

Dr Ashworth says the project hinges on the ability of farm machinery to detect weeds, differentially spray herbicides on to them, and then map those weed locations.

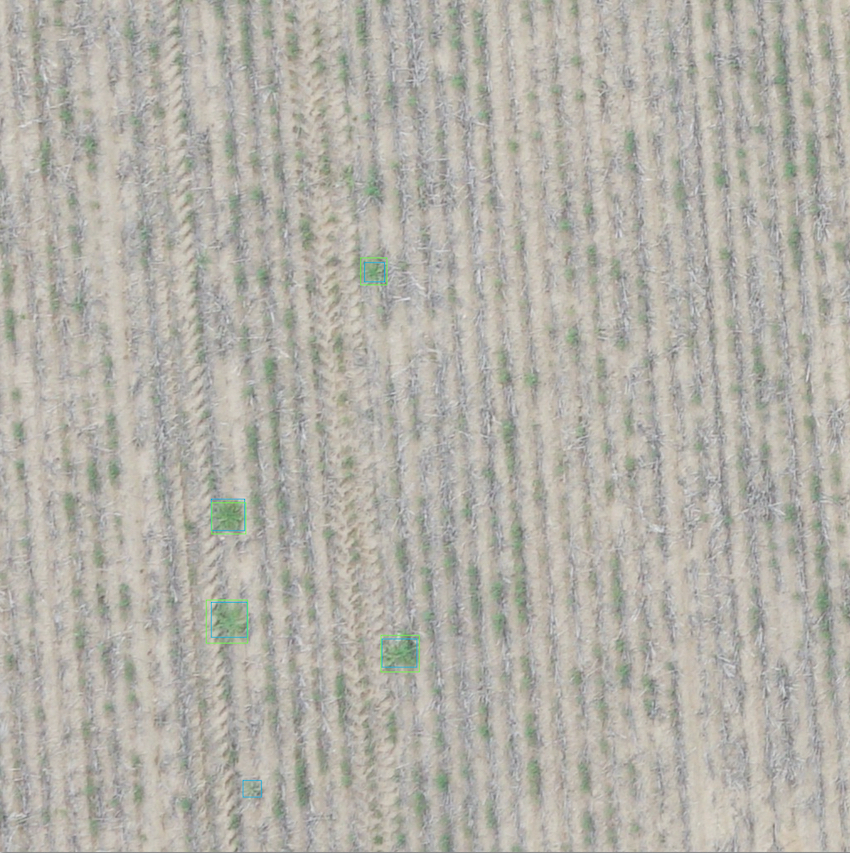

A new initiative is seeking to feed weed mapping and predictive weed-emergence models into the everyday operation of farm machinery. Photo: Melissa Powell

A new initiative is seeking to feed weed mapping and predictive weed-emergence models into the everyday operation of farm machinery. Photo: Melissa Powell

“This site-specific spraying implicitly maps where the weeds are in a paddock,” he says. “Notably, most of the farm machinery sold today is variable-rate or precision agriculture (PA) ready, which means that with site-specific application technology in place, it becomes possible to better exploit the weed map. This would allow for more proactive, targeted, follow-up action against the weeds and the seed they set.”

The potential for a major step-change in weed control outcomes exists because weed maps can now be used to derive predictive models about likely weed locations into the future based on knowledge of weed population dynamics.

Dr Ashworth points to published research work that found weed density – the parameter mapped during differential spraying – is a powerful predictor of weed seedbank size. That means a weed map can be used to model future weed threats (based on observations that a remnant portion of a seedbank will be dormant and germinate in subsequent seasons).

While seed dormancy can change with location and management, GRDC-funded research has quantified the seedbank dynamics of different weed species.

“If we know where the weeds are expected to be, growers have the opportunity to be proactive before patches appear, applying all herbicidal and non-herbicidal weed control tools to reduce the size of the weed seedbank for following seasons,” Dr Ashworth says.

Besides differential herbicide rates, he envisions the mapped zones taregted with additional tactics. These include:

- variably increasing the crop seeding rate to bring more competition to bear on weed germination;

- the targeted use of more-expensive pre and post-emergent herbicide products;

- targeted desiccation of problematic zones;

- improved use of harvest weed seed control, such as lowering the harvester front in weedy patches; and

- application of new technologies for variable-rate pre-emergent herbicide prescriptions based on soil layers and weed zones such as those developed in aligned GRDC investments, including with Syngenta.

“What we envision is data-based integration that allows the use of all machines and control options throughout the growing season in a targeted and near-automated manner, particularly against herbicide-resistant weed patches,” Dr Ashworth says.

In addition, he wants to bring sprayer camera technology and remote sensing technology to bear on the problem to detect impacts following a control measure. Such technologies are also targets for development work through other GRDC investments.

“One problem within our farming system is the lack of follow-up after weed control efforts, resulting in the seed-set of herbicide-resistant weed populations,” he says. “Sprayer camera technology, remote sensing and mapping could allow the effectiveness of control tactics to be assessed with each sprayer pass in the paddock. This would allow additional targeted weed control efforts before resistant weed populations set more seed.”

This is especially important given Australian farms are large and herbicide dependent. Consequently, increases in herbicide costs can force growers to use suboptimal mixtures or reduce the herbicide rate.

By zoning and monitoring weed management practices and working with machinery and PA analytics companies to make the process near-automated, opportunities exist to maximise crop profitability where weed burdens are low and to optimise weed control efforts (chemical and non-chemical) in high weed density areas.

“Spraying weeds amounts to dealing with the symptom,” Dr Ashworth says. “Work on harvest weed seed control has demonstrated that focusing and managing the seedbank produces dividends. Now we have the potential to couple what we know about weed ecology, population dynamics and integrated weed management with the power of digital agriculture and site-specific weed management technologies to target the seedbank in ways we haven’t been able to before.”

Project team assembled

Project activities are now underway. Leading up to this point were the negotiations that built up the team needed for the software integration and modelling. The objective is to target all WeedSmart Big 6 tools (that cut across chemical, mechanical, agronomic and cultural weed control tactics), which means diverse expertise and collaborations are harnessed.

Other researchers at the University of Western Australia involved in this study include Professor Ken Flower (AHRI director), Associate Professor Michael Renton (biological modelling and statistics expert), Dr John Duncan (spatial data science and data management expert) and Dr Michael Widderick (Queensland Department of Agriculture and Fisheries northern farming systems expert).

The national team is being built during the 2024 winter cropping season, which is essentially a pilot year of operations.

To ensure that the proposed new integrated control strategies are financially viable for growers to deploy, Dr Rick Llewellyn at CSIRO will examine the economics of the proposed, revamped integrated weed management strategies.

Key industry collaborators include Bayer Crop Science, InFarm and Data Farming for drone and cube satellite remote sensing services. The project is also leveraging connections and insights from other GRDC projects in site-specific weed management led by Syngenta, Nufarm, the New South Wales Department of Primary Industries and others.

There are several pre-existing weed models that simulate weed management and herbicide resistance over time, such as Weed Seed Wizard, Polygenic Evolution of Resistance To Herbicides (PERTH) and Ryegrass Integrated Management (RIM). This project aims to develop a model that is a spatial equivalent and includes predictions of weed germination, seed production and herbicide resistance, in addition to being informed by in-season images from satellites, drones and tractor and sprayer-mounted cameras.

The output from the model would be heat maps that predict weed locations, the ability to zone paddocks into differential weed zones for management purposes and ongoing monitoring of weed populations.

Additionally, Dr Ashworth is working with key agricultural technology companies that have experience building weed maps with green-on-brown and green-on-green technology. The project will sample seedbanks and weed patches to provide additional data to help build robust algorithms to map and zone paddocks.

These partnerships will see AHRI functioning as a central hub that works on data integration and modelling capabilities. The hub will then have spokes into the relevant industry sectors, with a grower steering committee overseeing the project’s focus and operations.

“We are aiming to use weed-related data in a new, more strategic and holistic way that brings all farm-available tools to bear on the problem in a user-friendly way for agronomists and growers,” Dr Ashworth says.

“Ultimately, I envision this new approach as creating an on-farm feedback loop that acts through farm machinery and farm management software to implicitly and continuously monitor and keep the weed seedbank in check.”

Target spraying post-emergent weeds

The digitalisation of agriculture has created openings to build in year-round surveillance targeting the weed seedbank, including through the use of satellite imagery. Photo: InFarm

Project partner, Craig White at Bayer Crop Science says that there is a growing recognition that PA machinery and its software capabilities offer opportunities to develop an enhanced arsenal of weed control options. This is a vision based on exploiting weed map data more fully for year-round control that is more flexible, more targeted, costs less and preserves the longevity of much-needed herbicides.

"Bayer Crop Science supports and participates in these developments," he says. "For example, the company is working closely with the Australian Herbicide Resistance Initiative and GRDC on an ambitious project to integrate weed map and modelling software into the operation of all farm machinery to better control weeds and drive down weed seedbanks."

As part of its portfolio of crop protection, seeds, traits, biologicals and digital tool development work, Bayer Crop Science has rolled out a new project in 2024 to develop weed scripts for use with boomsprays. This is envisioned as a low-cost, flexible software package that optimises herbicide choice and application for site-specific, post-emergent weed control.

This project’s main focus is broadleaf weeds in wheat across Australian grain growing regions.

"Currently, post-emergent herbicides are applied across entire paddocks irrespective of where weeds are located," Craig White says. "This inefficiency is a huge cost to growers. Our development work aims to give growers the ability to select the optimum post-emergent herbicides and only use them where they are needed for maximum and long-term weed control."

The weed map data for this project is generated from images obtained using unmanned aerial vehicles. The data processing capability is being developed to accurately identify and map weeds in-crop. This results in weed scripts that instruct the operation of sections, or individual nozzles, on boomsprays.

This core technology will be commercialised in the form of a cost-effective and scalable commercial product that makes possible site-specific in-crop herbicide application via boomsprays. Delivery to growers is scheduled for 2027-28.

Reducing herbicide dependency

AHRI director Professor Ken Flower says that developing the new GRDC project fits in well with AHRI’s overarching goal of developing cropping systems with reduced dependence on herbicides.

Professor Ken Flower, director of the Australian Herbicide Resistance Initiative. Photo: GRDC

Professor Ken Flower, director of the Australian Herbicide Resistance Initiative. Photo: GRDC

With six applications of herbicide per paddock per year not uncommon in Western Australia, Professor Flower says herbicides form the dominant mode of weed control in cropping systems. That reliance, however, has serious repercussions as herbicide dominance places weeds under continuous selection pressure, resulting in resistance – sometimes to multiple chemical groups.

“Even with integrated weed management (IWM) practices in place, we seem to be locked into a high herbicide system and that will inevitably lead to resistant weeds,” Professor Flower says. “We are also facing the potential future loss of key herbicides due to issues around social licence given public and regulatory concerns.”

The sector is also facing increased costs for chemicals as well as increased herbicide development and regulatory costs.

As well as maintaining the effectiveness of existing herbicides, AHRI is at the forefront of developing cropping systems with reduced herbicide reliance. Key to this development is a focus on agronomic solutions and on a greater use of data and computational sciences, especially when they create opportunities for non-chemical and mechanical strategies.

What is envisioned is an integrated toolkit built into a farm’s operations. Working with farm management software companies, machinery companies, agronomists and growers is key to that vision. Examples of this might include:

- earlier detection of problem weeds/resistance;

- differential sowing rates to increase crop competition over weeds;

- sowing a mix of varieties in weedy zones to strategically introduce more competitive (but possibly less productive) varieties;

- collaborations with other universities and companies that are developing novel non-herbicide options, such as nucleic acid sprays and targeted mechanical cultivation; and

- an integrated, whole-of-system approach to ensure the seamless adoption of any new weed management technology into a farming system.

“The aim is not to eliminate herbicides; rather, it is to make their use more sustainable by monitoring weed patches and taking a longer-term, more-targeted, multi-tactic approach,” Professor Flower says.

“With companies producing machinery focused on weed control in the here and now, a gap in sustainable practices has been building that has been patched over with herbicide reliance. It’s that gap that AHRI and its research and commercial partners across the country are seeking to close with the current set of R&D work.”

More information: Mike Ashworth, mike.ashworth@uwa.edu.au; Craig White, craig.white@bayer.com