One-way disc ploughs offer a lower-cost alternative to mouldboard ploughs to ameliorate constrained soils, with added scope to work across a wider range of soil types.

From 1900 to the 1970s disc ploughs were favoured over mouldboard ploughs by Australian grain growers due to their lower draught requirements, faster mode of operation and ability to break up heavy soils. During this period, one-way disc ploughs were used to tip soil on its side as a primary tillage operation.

However, these ploughs can be modified to work deeper than traditionally intended to more effectively invert the soil. Additionally, the unpowered, rolling action of the disc of one-way ploughs makes them better able to ride over rocky ridges and cemented gravels than a mouldboard plough, enabling them to work in a wider range of soil types.

Modifications

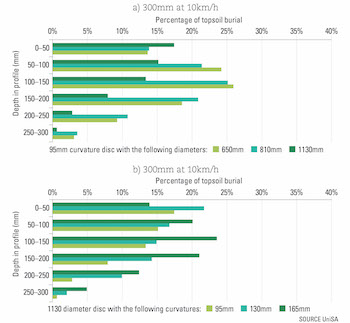

Figure 1: DEM simulation showing percentage of topsoil burial at each 50mm depth increment for (a) 650mm, 810mm and 1130mm diameter discs with 95mm deep curvature and (b) 95mm, 130mm and 165mm deep curvatures for 1130mm diameter disc.

Figure 1: DEM simulation showing percentage of topsoil burial at each 50mm depth increment for (a) 650mm, 810mm and 1130mm diameter discs with 95mm deep curvature and (b) 95mm, 130mm and 165mm deep curvatures for 1130mm diameter disc.

Australian growers have been innovative in modifying one-way ploughs for greater and deeper soil inversion.

This typically involves removal of every second disc and fitment of larger-diameter discs, allowing deeper working and more space for soil to turn over.

Often known as ‘Plozza ploughs’ after the WA growers Ben and Sean Plozza who first developed the concept, the discs are usually more concave (have a greater ‘dish depth’) with greater curvature, assisting the soil to roll beyond 90 degrees and end up inverted.

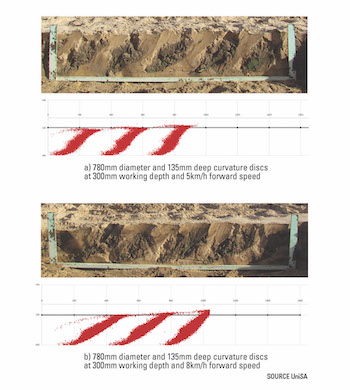

Figure 2: Field test performance of modified one-way plough compared with DEM simulation results for an operating depth of 300mm with 780mm diameter and 135mm deep curvature discs at speeds of (a) 5km/h and (b) 8km/h.

Figure 2: Field test performance of modified one-way plough compared with DEM simulation results for an operating depth of 300mm with 780mm diameter and 135mm deep curvature discs at speeds of (a) 5km/h and (b) 8km/h.

The plough’s capacity to work deep is improved by increased break-out pressure on the jump arms and increasing the ballast (weight) on the plough if required.

Insights into the operation of one-way disc ploughs to optimise set-up have been assessed through the use of discrete element method (DEM) simulations carried out by researchers at the Agricultural Machinery Research and Design Centre at the University of South Australia.

As the disc is a passive tool with its rotation driven by the force of the soil on the disc, it requires more complex simulation to accurately model its operation and the resulting impact on soil movement.

DEM simulation results have shown that increasing the disc diameter increases the topsoil burial if the disc has a curvature depth that is approximately one-sixth of the disc diameter. Figure 1(a) shows that increasing the disc diameter without changing the curvature does not improve the topsoil burial.

However, Figure 1(b) shows that increasing the curvature depth of a 1130-millimetre diameter disc increases the topsoil burial.

As depth of work is increased for a one-way disc plough, the rotational speed of the discs reduces for a fixed forward speed.

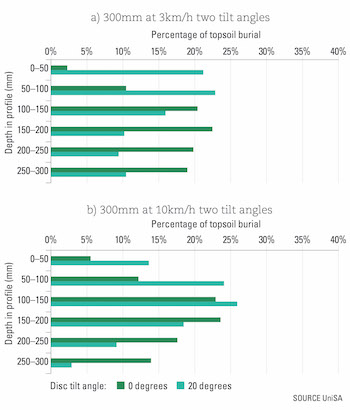

Figure 3: DEM simulation of the effect of tilt angle of the discs at a 300mm working depth and an approach angle of 45 degrees at 3km/h (top) and 10km/h (bottom) forward speeds on percentage topsoil burial in 50mm depth increments down the profile.

Figure 3: DEM simulation of the effect of tilt angle of the discs at a 300mm working depth and an approach angle of 45 degrees at 3km/h (top) and 10km/h (bottom) forward speeds on percentage topsoil burial in 50mm depth increments down the profile.

DEM simulation results showed that increasing the operation depth reduced the amount of topsoil buried into deeper layers. Increasing forward speed improved topsoil burial up to a specific tillage depth (about 200mm).

At lower speeds the percentage of topsoil buried into deeper layers increased at 300 and 350mm operation depths, while it decreased at 200 and 250mm operation depths.

Field tests and DEM simulated results using a deep-working modified one-way plough also showed similar trends. It was found that at slower speeds, more distinct and vertical burial profiles were obtained (Figure 2a and 2b).

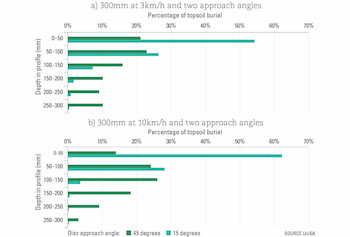

Simulation results with modified working angles of the one-way plough discs showed that reducing the tilt angle (angle of the effective disc face, edge to edge, relative to the soil surface) from 20 degrees to 0 degrees (disc face vertical) and increasing the approach angle (angle of the effective disc face relative to the direction of travel) from 15 degrees to 45 degrees could increase topsoil burial (Figures 3 and 4).

Figure 4: DEM simulation of the effect of approach angle of a one-way plough at a 300mm working depth and 3km/h (top) and 10km/h (bottom) forward speeds on percentage of topsoil burial in 50mm depth increments down the soil profile.

Figure 4: DEM simulation of the effect of approach angle of a one-way plough at a 300mm working depth and 3km/h (top) and 10km/h (bottom) forward speeds on percentage of topsoil burial in 50mm depth increments down the soil profile.

The complexity and number of variables involved in disc ploughs greatly affected their operation and quality of work, based on the initial analyses with DEM.

Further investigation is needed around adjusting the disc plough components and potentially improving and optimising their use, whether that be for better inversion or greater soil mixing.

More information: Dr Chris Saunders, UniSA, 08 8302 3664, chris.saunders@unisa.edu.au; Dr Stephen Davies, DPIRD, 08 9956 8515, stephen.davies@dpird.wa.gov.au