With climate change and ecological sustainability top-of-mind for most grain growers, startup company Loam Bio is looking to address one of the key challenges – soil productivity – with seed inoculum products that can have potential to increase soil carbon in cropping systems.

Soils are the largest terrestrial carbon reservoirs, but intensive farming has meant that in agricultural soils this reservoir has been depleted by up to 60 per cent in some areas.

Loam Bio co-founder Tegan Nock says that by increasing soil carbon not only do we sequester more carbon, but this also improves soil health and structure, as well as increasing water-holding capacity and nutrient availability – boosting crop yields and system sustainability.

“The Loam Bio team is leveraging the mechanism that microbes use in natural systems to develop seed inoculums that build soil carbon,” Ms Nock says. “It gives growers the ability to improve yields and stabilise soil carbon.”

Carbon cycling and microbes

Loam Bio is tapping into the improved understanding of carbon cycling. Atmospheric carbon dioxide is sequestered in soil via a multi-stage process. Plants first convert carbon dioxide into simple sugars via photosynthesis.

Some of these sugars are then secreted into soil in the form of root exudates. These substances are rich in labile carbon compounds and are utilised by microorganisms at the plant-soil interface. Through this process, carbon is eventually deposited in soil as soil organic carbon in aggregates and in mineral-associated fractions. The carbon is retained at varying rates, depending on a range of biotic and abiotic factors.

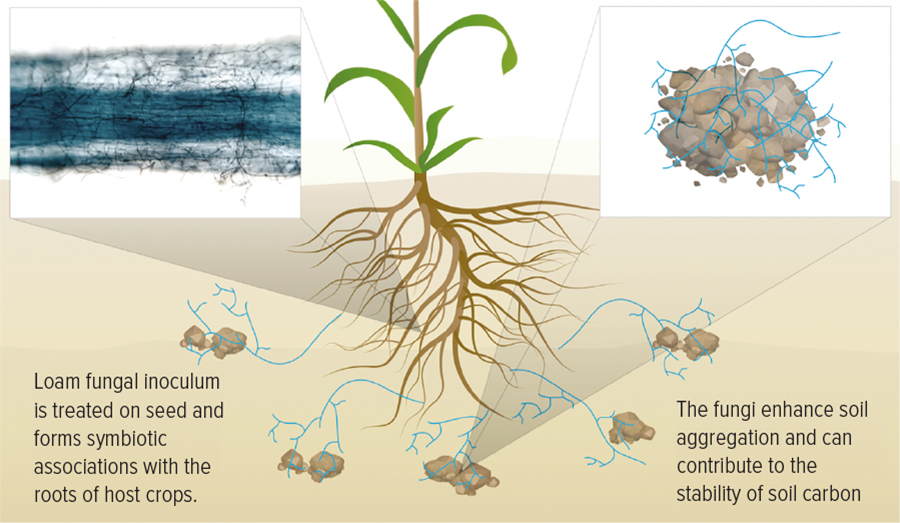

Novel Loam Bio CarbonBuilder seed inoculum in action. Source: Loam Bio

Soil microbial communities have diverse functions and physiology that can contribute to retaining and stabilising soil carbon. Emerging technologies have allowed researchers to identify and isolate soil microorganisms with these characteristics, and develop microbial formulations that can enhance soil carbon.

“Since we acquired the foundational research from the University of Sydney and established the business in 2019, we have invested in a further 36 greenhouse trials, 198 small-plot trials and analysed 57,789 soil samples in the lab to substantiate and validate the research,” Ms Nock says.

Identified through bioprospecting, Loam Bio has screened more than 2500 soil fungi for their performance and is focussing on a functional group of fungi known as dark septate endophytes. These are a diverse group of fungi that occur in all major ecosystems. They colonise plant roots, forming complex relationships with plants and have been shown to improve growth, health and nutrition of the host plant. The plants and microbes work together to build carbon in the soil and keep it there in aggregates bound by fungal filaments.

Loam’s research and development has focused on applying these microbes as a live seed inoculum prior to sowing to help kick-start the relationship and are continually evaluating their performance in boosting soil carbon levels and plant performance.

Loam Bio support and collaboration

“It is challenging to build stable soil carbon in cropping systems so to underpin our product development, we have established a strong science program partnering with global leaders to expand the understanding of our technology’s impact,” Ms Nock says.

Australian collaborations include Western Sydney University, the Australian National University and the University of Queensland, where the focus is on further developing and understanding various aspects of the technology.

The GrainInnovate program has provided ongoing support and strategic advice throughout the growth of Loam Bio’s business, starting as a seed investor.

Funding from investors, including Horizons Ventures, CSIRO’s Main Sequence Ventures, the Australian government’s Clean Energy Finance Corporation and GrainInnovate, has seen Loam Bio move from small plot trials demonstrating total carbon increase against control of three per cent in barley and five per cent in canola, to an expanded national field trial program in 2023.

Understanding Loam’s technology performance across the variability of conditions in Australian cropping – soil, weather, systems, inputs – is key, and Loam has grown their in-field trial program, partnering with agronomy networks, grower groups, and corporates.

“We have partnered with leading companies like GrainCorp, along with agronomy networks, to ensure we are developing solutions that integrate into existing Australian cropping systems.”

With their academic partners, Loam has developed the capabilities to better understand and measure stable carbon at-scale, which enables better management of carbon variability from season to season. This, coupled with a broad geographic trial program that seeks to understand building stable soil carbon across Australia’s variable soils, is providing growers with greater confidence that stable soil carbon can be built in their systems.

Case Study: Carbon capture for crops and climate

Best-practice farming principles are fundamental for Steve Nicholson’s farming business.

“A systems approach with attention to sound science is required to drive both profitability and sustainability of our farming system,” Steve says.

“This involves attention to planning, preparing, controlling weeds and diseases, selecting the best variety for the best sowing time, operating well-maintained machinery and ensuring timely operations.”

Steve is a member of Loam Bio’s SecondCrop carbon project program, which combines the use of Loam Bio’s recently released CarbonBuilder microbial technology with farmer-first projects.

Loam Bio staff working with Steve Nicholson to build soil carbon on his property ‘Eniver’ to benefit both crops and climate. Photo: Rachael Lenehan Photography

SecondCrop refers to taking a second crop from a paddock in the form of carbon credits.

Steve operates ‘Eniver’, a mixed farm of about 4000 hectares between Forbes and Grenfell in New South Wales. Annual rainfall is 620 to 650 millimetres and the soils range from heavy black to red gravels. About 2500 breeding ewes are run on the property, peaking at up to 5000 head with lambs, while cattle are opportunistically stocked mainly in the creek country, with steers bought in, fattened, and sold.

Building soil carbon content is fundamentally a good thing as it is a source of healthier crops and pastures with bigger root systems, which drives our productivity.

Steve has been farming ‘Eniver’ for 22 years and in that time has adopted minimum-tillage practices and ensured constant ground cover to build carbon. He has been regularly soil testing and has seen organic carbon content rising every year.

He has experimented with various soil amendments to boost soil health in the past, including phosphate solubilising bacteria. It is this pursuit of improving soil health that ignited his interest in the activities of Loam Bio.

“Loam Bio’s endophytic fungi discovery is exciting, but it is also its innovative business model that could be a game-changer,” Steve says.

“If we can fix carbon in the soil in a less-labile form, we stand to not only boost soil health but also sequester carbon more effectively, reducing carbon dioxide release to mitigate climate change.”

Steve is one of the first growers to use Loam’s recently released CarbonBuilder seed inoculum outside of trials and is encouraged by the recently released 2022 small plot trial data.

“This is entirely feasible with the total carbon increase seen in Loam’s 2022 small plot trial data for canola and barley of between three per cent to five per cent against controls.”

“Loam Bio works with a grower to assess the carbon status of your paddocks and then to build it. Loam Bio’s business model is to share the Australian carbon credit units generated, so there is little work or financial investment required by a grower.”

More information: LoamBio website.