Recent heavy downpours and more rain on the forecast has eastern Australian grain growers bracing for another wet harvest, with logistical and grain quality issues already front of mind.

While growers are very much at the mercy of the weather when it comes to being able to harvest crops, they can start to prepare their silos to store grain above the deliverable moisture content to open up selling options.

This is the topic of the GRDC's most recent podcast, where GRDC National Grain Storage Extension Project Coordinator, Chris Warrick discusses what growers should be doing now to prepare their silos to store wet grain. You can listen here, or via most popular podcast platforms.

Mr Warrick says while some growers might choose to delay harvest, giving crops the chance to dry out and get back to the desired deliverable moisture content, others might have to harvest wet grain to avoid future rainfall events.

“Preparing silos so growers have the option to take grain off the above deliverable moisture content is a tool they can use to manage the difficult logistics of a wet harvest,” he says.

“The ideal setup at a time like this is having drying facilities available; however, that won’t be the case for a lot of growers, and it may not be possible for them to access this equipment so close to harvest.

“The second most common management option, and one that can be underutilised by the industry, is aeration cooling. Growers can use aeration cooling to hold grain, preventing it from moulding, until it can be dried or blended with dry grain to sell.”

Mr Warrick says the most important factor to consider when using aeration cooling to store wet grain is ensuring the system is set up to match what growers want to do with it.

“Drying with aeration requires really high airflow. Growers will need 15 litres of air per second per tonne or more to carry the moisture out of the grain,” he says.

“Aeration cooling only requires 2-4 litres of air per second per tonne and can be retro-fitted to cone bottom silos, sheds or bunker sites.

“If you are going to store grain with higher moisture, make sure you’re monitoring it regularly. Smell the air, check the temperatures, and ensure it’s cooling down, not heating up.

“When using aeration cooling fans to hold higher moisture grain, growers will need to run fans continuously whenever ambient conditions are under 85% relative humidity, regardless of temperature. Without constant air-flow, higher moisture grain is likely to heat, sweat and turn mouldy.

“I’d also advise growers put actions in place to make this easier now - making sure they can monitor their systems easily and ensure the air running through the grain is meeting expectations.”

Mr Warrick said if growers are planning to retain seed from this harvest, they should be prioritising these crops to maintain the seed’s quality.

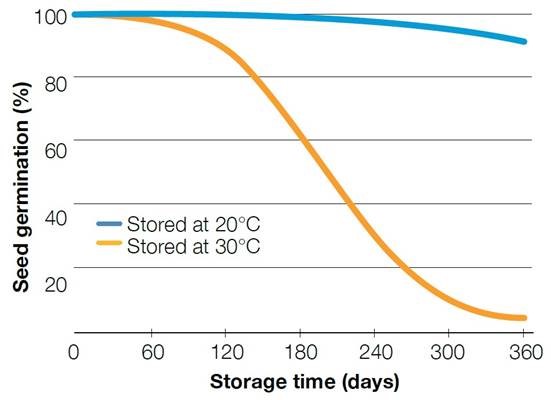

This graph shows the influence of temperature on wheat germination percentage when stored at 12% moisture content. Image: CSIRO

“Give priority to retaining seed, get it in the silo and store it at a low moisture content and in cool temperatures,” he says.

“This will ensure a high germination percentage and greater seedling vigour can be maintained through to sowing in 2023.

“Ideally seed should be stored in silos with aeration cooling, an alternative is to harvest seed during the cooler parts of the day as grain will hold that cooler temperature during storage.”

The GRDC YouTube channel has a full video series on effective grain storage, including aeration cooling and general hygiene.

GRDC also has an updated fact sheet on saving weather damaged grain for seed that growers can access via the website.