Key points

- Testing phosphine residue in trucks at receival sites is required for operator safety and label compliance

- Sampling and testing methods require further research and development to avoid penalising those doing the right thing

- Using a phosphine meter on farm is the surest way to avoid truckloads being rejected

There is no argument that testing grain deliveries for phosphine residue is needed to ensure operator safety and label compliance. However, some preliminary research has revealed more work is needed to develop an appropriate testing protocol. Without further development, the current testing method used at some grain receivals threatens costly rejection of truckloads of grain, including operators who are following phosphine label directions.

The Safe Work Australia standard for phosphine exposure is 0.3 parts per million (ppm) time-weighted average (TWA), referring to the air people are breathing over an eight-hour workday and 40-hour week.

The current test method used by some receival sites involves a spear sample into the grain requiring a phosphine reading of less than 0.3ppm. The difference is that TWA gas concentrations are taken in the air operators breathe, rather than from within the grain stack.

The phosphine label also states that “ventilation of structures is complete only when the phosphine concentration measured at appropriate locations in the enclosure and work area are below TWA exposure standard of 0.3ppm”.

To ensure operator safety, further research is needed to compare gas concentrations from the air within the grain bulk versus the air that operators breathe. Appropriate gas concentrations at these measuring points need to be identified.

Preliminary research

Phosphine fumigation trials conducted by Queensland Department of Agriculture and Fisheries (DAF) in 2019 explored the relationship between phosphine gas concentrations trapped in the air between grain after venting and the gas levels that someone could potentially breathe at the grain surface.

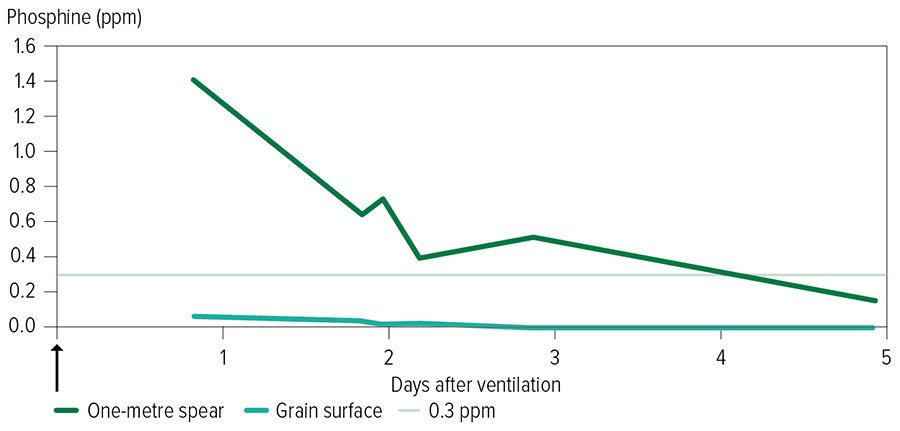

After a 10-day fumigation and 24-hour fan ventilation (as per label directions), phosphine gas measurements were taken at a depth of one metre in the grain using a gas probe. A second test measurement was taken at the grain surface.

Results showed that phosphine gas concentrations from the 1m probe within the grain were as high as 1.4ppm after venting (Figure 1). In contrast, gas concentrations on the grain surface were much lower at 0.06ppm, well below the threshold limit value – time-weighted average (TLV-TWA) of 0.3ppm.

Figure 1: Phosphine gas measured at the grain surface versus a one-metre spear placed into the grain stack. The black arrow shows when ventilation was completed. The trial consisted of a 10-day fumigation period followed by 24-hour ventilation with aeration fan. Grain was augured out and back into the storage two days after ventilation was completed.

Source: Queensland Department of Agriculture and Fisheries

These results indicate that further industry-based research and development is required to clarify the relationship between gas levels measured when probing grain in trucks and gas levels measured in air that workers are breathing. Gas readings taken within a grain bulk are significantly higher than the levels present at the grain suface, let alone what might be measured where workers are operating. This preliminary data suggests TWA sampling locations need to be reviewed to ensure a safe working environment without unnecessarily rejecting grain deliveries and potentially penalising operators who are performing successful fumigations and venting as per the label directions.

Venting below 0.3ppm

Research conducted by DAF in 2017 revealed that the label-directed ventilation period of five days, or one day with aeration fans, is unlikely to exhaust phosphine below 0.3ppm in a grain spear sample.

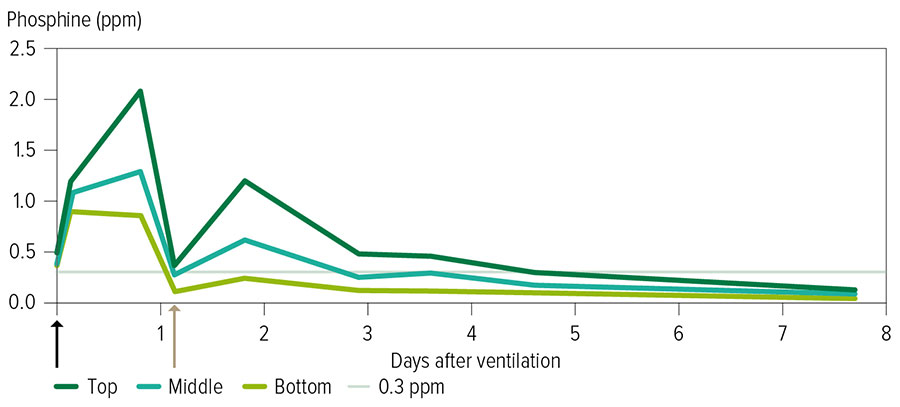

After a seven-day fumigation and 24-hour ventilation using an aeration fan, gas measurements were taken within the grain bulk at the top, middle and bottom of the silo for the following eight days. While the measurements taken immediately after the aeration-assisted ventilation were low, they quickly rose back up from 0.8 to 2.0ppm within 24 hours (Figure 2).

Figure 2: Phosphine gas measured at three points within the grain bulk in a silo following a seven-day fumigation and 24-hour ventilation with aeration fan. The black arrow shows when ventilation was completed. The brown arrow shows the temporary drop in gas readings after the grain was augered out and back into storage. What is evident is that grain slowly desorbs phosphine over time and, in this example, took four to five days to fall below 0.3ppm.

Source: Queensland Department of Agriculture and Fisheries

Augering the grain out and back into the silo to replicate outloading and delivery temporarily reduced the gas readings. But the gas concentration again rose from 0.2 to 1.2ppm before declining below the target 0.3ppm four to five days after ventilation.

Avoiding rejection

Until further research and development is done by industry, growers who deliver to sites using a 0.3ppm gas limit measured within the grain stack may need to extend their ventilation periods by at least four days.

Venting time might need to be increased when the grain is cold, when the fumigation exposure time was extended beyond label directions or in storages without aeration fans or with limited vent openings, such as large silos and grain bags.

To ensure compliance and avoid truckloads of grain being rejected, growers can use phosphine meters – Drager Pac 8000 or Silo Safe – to measure gas concentrations within the grain stack before outloading. Ensure measurements are taken at least 24 hours after aeration fans are turned off or grain has been moved to avoid a false low reading.

More information: Philip Burrill, 1800 WEEVIL, info@storedgrain.com.au; Drager Pac 8000 from Graintec; Silo Safe from Canary.