On-farm grain storage allows growers to improve harvest efficiencies and capture higher-value markets. These advantages are undermined when the storage conditions result in a deterioration of grain quality. One of the most effective means of maintaining product quality includes adding aeration to storage facilities.

When correctly designed and managed, aeration achieves cooler grain temperatures and uniform grain moisture conditions in storages. This reduces problems with insect pests and moulds. It also helps maintain grain quality attributes such as seed germination and pulse seed colour, along with oil and flour quality. It is also important to combine aeration cooling with good hygiene, monthly storage checks and records, along with good fumigation practices. Collectively these management strategies form the foundation for successful grain storage.

Aeration also introduces other advantages including the efficient ‘venting’ of gases after a phosphine fumigation and the ability to safely store higher-moisture grain for short periods by continually running fans until drying or blending options are available.

In the longer term, high-quality grain storage allows growers to build a reputation around quality product supply and this is likely to improve market opportunities for growers.

Effective aeration – what does it look like?

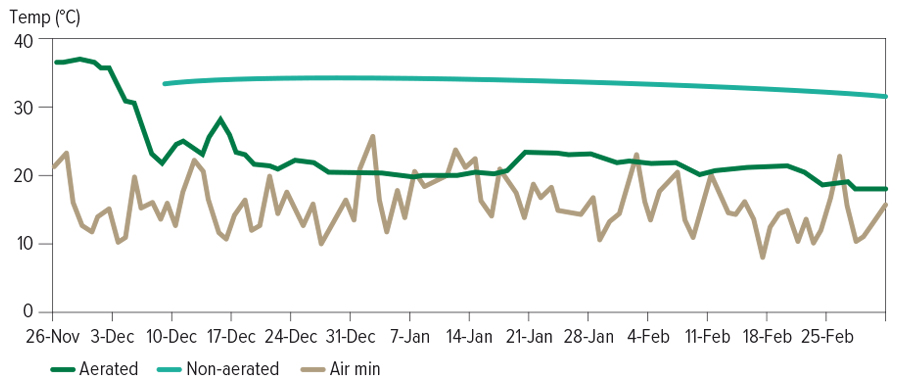

During summer and early autumn, growers should aim to achieve grain temperatures of 18° to 23°C with well-managed aeration cooling. For the winter and spring period, the target is grain temperatures of less than 15°C (See Figure 1).

Figure 1. A comparison of grain temperatures in two silos of wheat. The silo with no aeration maintained grain temperatures above 30°C for more than 3 months, ideal breeding conditions for storage pests. The aerated silo had grain temperatures in the low 20°C range. Source: Barry Wallbank, formerly NSW Department of Primary Industries

Aeration equipment for the job

Aeration can be designed to suit a variety of storage types, including grain sheds, bunkers, grain rings and most silos. It is also often retrofitted to older silos. The four main components are fans, ducting, roof vents and a reliable method for automating fan run times when cooler, dry air is available.

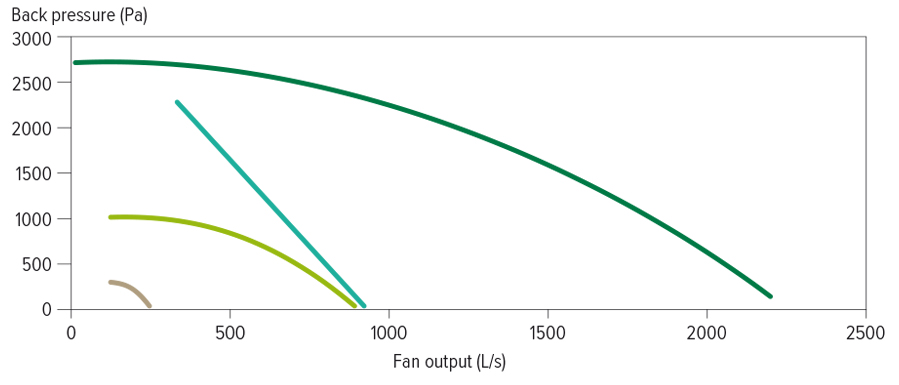

Aeration fan performance can vary significantly (as demonstrated in figure 2). Fan size and the number of fans per silo are common areas for confusion. It usually requires an “experienced aeration specialist” to provide good advice to growers, and to some silo suppliers, when it comes to fitting appropriate fans to storages. There are a number of important considerations that include:

- The silo size (height and width);

- The electricity supply available;

- The grain types to be stored; and

- The intended purpose of aeration

- Is the system for aeration cooling (airflow two to four litres per second per tonne)?

- Is the system for aeration drying (airflow 15 to 25L/s/t)?

Figure 2. Variation in aeration fan performance of four fans used in grain storages. Source: Philip Burrill, Andrew Ridley Queensland Department of Agriculture and Fisheries, Chris Saunders UniSA

Aeration ducting comes in two common types for elevated cone base silos; round perforated tube ducting, or the house-shaped ducting fixed to the silo’s cone base. Flat-bottom silos usually have ducting channels incorporated into the silo’s concrete base. Ducting length, strength, location and size of perforation holes or slots, are all involved in achieving optimum airflows and distribution. Ability to clean and remove grain residues under ducting for silo hygiene is important for both cone base or flat-bottom silos.

The vent size/area needs to be appropriate to suit the fan output. Avoid adding additional operating back pressure to fans by restricting airflows out of a silo. Fan airflow should never be used to lift heavy vent lids, or constantly work against lid springs.Aeration silo roof vents can be as simple as a “tin hat with mesh” used on the centre-fill top hatch of smaller silos (70 to 150t), or the common “goose neck” roof vents seen on larger silos.

For all sealable silos, vents require simple, effective systems for creating a gas-tight seal during a fumigation. Aim to have easy access to roof vents for maintenance on the mechanism and rubber seals.

Operating the aeration system effectively

Running the fan during the best ambient conditions will achieve cool grain temperatures and uniform grain moistures in storage. A good-quality automatic aeration controller is recommended as the most reliable method of ensuring fans are running at optimum times.

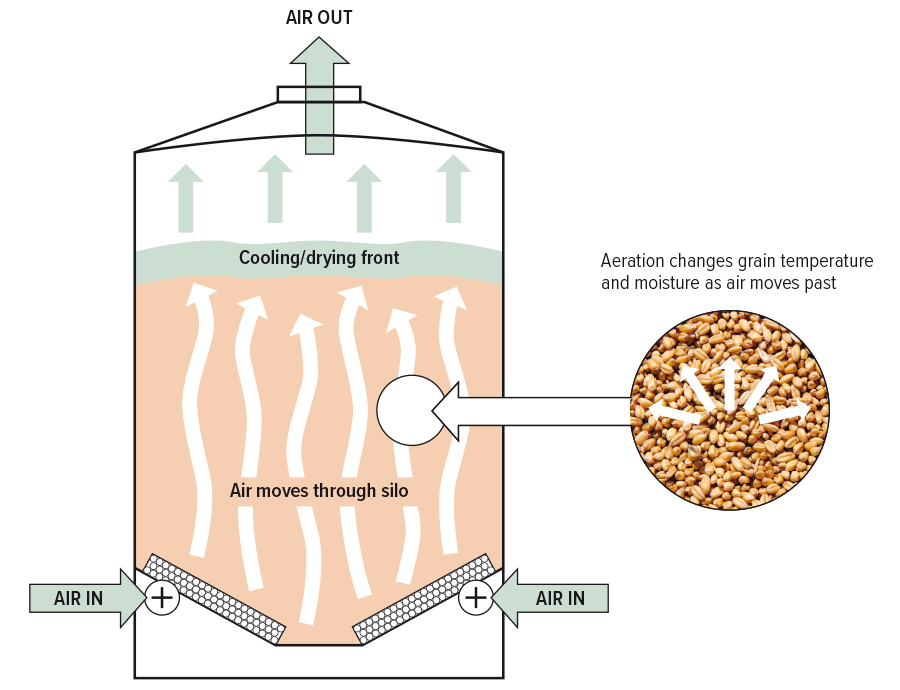

Aeration cooling aims to push a series of ‘cooling fronts’ through grain, starting from the base of the silo (See Figure 3).

Figure 3. Cooling / drying fronts in the aeration process. Source: C. Newman

Manual operation of fans

For aeration cooling, there are three stages fans should run through from when grain is first loaded into a silo at harvest time.

- “Continuous”: As soon as enough grain covers the ducting, turn on aeration fans. Run continuously (24 hours/day) until the first cooling front comes through to the top of the silo (usually in three to five days).

- “Rapid or purge”: Run the fans for approximately nine to 12 hours per day for five to seven days after the continuous stage. Select cooler night air, but avoid extended periods of high humidity (more than 85 per cent relative humidity), ensuring you avoid periods of fog, mist or extended rainfall.

- Finally, the longer-term “Protect or maintenance” phase begins. Operate fans for about 100 hours per month, selecting cool, mostly dry air from two to three days per week.

Aim to invest in an automatic aeration controller, as it will achieve more reliable grain cooling results when compared with manual fan operations.

Automatic controller operation of fans

Some brands of automatic aeration controllers have the advantage of simplifying fan operations by automatically switching fans through the three stages outlined above. The controller will select fan run times by continually checking ambient temperature and humidity levels. When in the final “protect” mode the controller selects the best available air (cool and dry) for approximately 100 hours of fan run time per month.

Time proportioning controllers (TPC) are the most widely accepted aeration control system used in Australia. Growers should seek advice prior to purchase to ensure a good-quality aeration controller is selected to suit the storage facility. Suppliers should provide after-sales support and parts if required.

Maintaining and checking aeration equipment

There are a few necessary checks and maintenance steps to ensure that the aeration system is doing its job.

- Before harvest, manually test-run fans on silos to check for electrical faults. Inspect and clean fan impellers on older aeration fans.

- When sieving grain each month to monitor for storage pests, also use a grain temperature probe to check if target grain temperatures of 18° to 23°C during summer time and less than 15°C during winter months are being achieved.

- Check the hour meter on the aeration controller to ensure fans are averaging run times of approximately 100 hours per month in ‘protect’ mode.

- At least once a year, use a good-quality portable temperature and relative humidity reader to check the aeration auto-controller’s sensor has not been damaged and is reading correctly.

More information: Philip Burrill, Chris Warrick, Ben White, 1800 WEEVIL (1800 933 845), info@storedgrain.com.au

Useful resources: