Stubble retention benefits are well documented, including nutrient recycling, reduced erosion, improved rainfall infiltration and reduced moisture evaporation. But as cropping systems evolve and new equipment comes on stream, just how much residue can be retained and what are the implications?

These were the questions growers were raising about stubble management aspects of the new ‘strip and disc’ system, which is gaining interest in Western Australia. It has led to a GRDC-invested project through the National Growers Network, managed by the Liebe Group.

Chris O’Callaghan, who is leading the project for Liebe Group, says the checklist of queries on the subject from growers was quite extensive, encompassing:

- Is there greater soil moisture retention?

- Is there lower weed germination due to less disturbance?

- Are there improvements to soil structure?

- What are the implications for disease carryover?

- What are the practicalities of sowing into a high stubble load?

- Does the extra stubble cause nitrogen tie-up in thicker stubble?

- What are the implications for harvest weed seed control?

- Is there increased fire risk over summer?

- How is spraying efficacy maintained in taller stubble systems?

- How is stubble management affecting frost risk?

“As we are seeing property sizes increasing in Western Australia, growers are adopting new machinery with which they can achieve operational efficiencies,” Mr O’Callaghan says.

“Using a combination of disc seeders and stripper fronts, sowing and harvesting operations can be faster. The system works best with narrower row spacing and higher-yielding crops. It leaves taller, standing stubble, which may play different roles in different environments that we do not as yet fully understand.

Tall stubble refers to taller than ‘standard’. Currently, many growers within WA would harvest around 15 centimetres – beer can height – above ground level, and by doing so ensure they collect weed seeds for burning or destruction.

“The taller, ‘stripped’ stubble left by the stripper front can be around 60cm, which means less material going through the header and spread out the back.”

New machinery including double-disc seeders (top) and stripper fronts (bottom) are increasing residue retention with taller standing stubble and improving operational efficiencies. Photos: Evan Collis

About the project

The Liebe Group is collaborating on the project with Facey Group, Stirlings to Coast Farmers and Corrigin Farm Improvement Group – along with an experienced team of researchers, advisers and economists from the Department of Primary Industries and Regional Development, Statistics for the Australian Grains Industry West (SAGI West) and Charles Sturt University.

The project involves four demonstration sites across the low, medium and high-rainfall zones of WA. Each site is hosting one grower-scale demonstration with two standard treatments at all sites (stripper front with disc seeder and draper front with tyne seeder) and at least one treatment based on the local host grower’s input.

“The project presents the opportunity to observe and quantify the differences between standard and tall stubble systems to then provide recommendations as to how they are best managed,” Mr O’Callaghan says.

Treatments were implemented during the 2021 harvest and trials will continue over three growing seasons until December 2024.

A range of monitoring and measurements are being conducted at each site, including spray efficacy testing, crop establishment counts and weed counts, crop disease assessments, and seeding and harvest efficiency.

Any new system has associated costs and the project will document these together with developing a risk/reward profile to support growers in applying the step changes required for profitability.

“An e-booklet will be produced as part of the project to showcase all demonstration results, economic analysis and return on investment data, as well as key learnings to further inform decision-making. Videotaped grower case studies will also be produced.”

Preliminary findings

From the first season’s measurements, the researchers are beginning to build the dataset to evaluate the pros and cons of tall stubble systems, Mr O’Callaghan says.

Stubble biomass measurements are being collected at both post-harvest and pre-seeding timing to assess stubble degradation over summer as well as to track stubble loads over time.

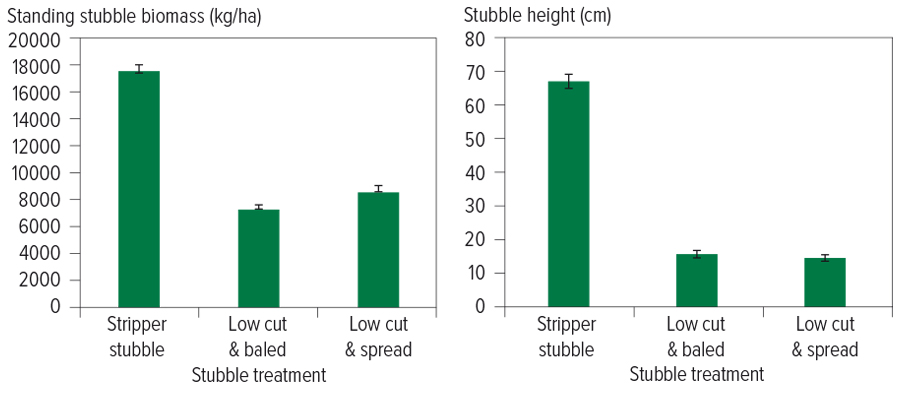

An example for stubble biomass prior to seeding is shown for the Facey site in Figure 1, with the strip-and-disc system retaining well over double the amount of the spread system.

Figure 1: Example of (a) stubble loads and (b) heights at the Facey site prior to seeding in 2023.

Source: Liebe Group

“The sheer volume of stubble at many of the sites caused issues particularly with the stripper front stubble, with bulldozing and hairpinning common problems.”

The soil moisture measurements in 2022 were inconclusive; however, in 2023 and 2024 more-detailed measurements will be taken to capture moisture changes and temperatures across different stubble architectures.

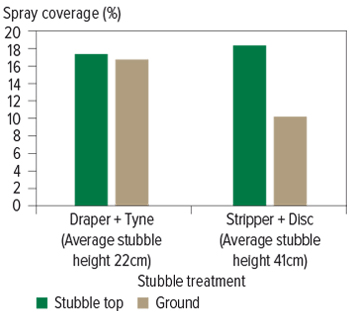

An example of the spray cover percentage for the Liebe site is shown in Figure 2, showing the difficulty there is for spray to penetrate the tall stubble, with more than 40 per cent loss of spray at ground level.

Figure 2: Spray coverage (%) for the Liebe site.

Source: Liebe Group

“Growers are experimenting and finding better penetration with smaller spray droplet size.”

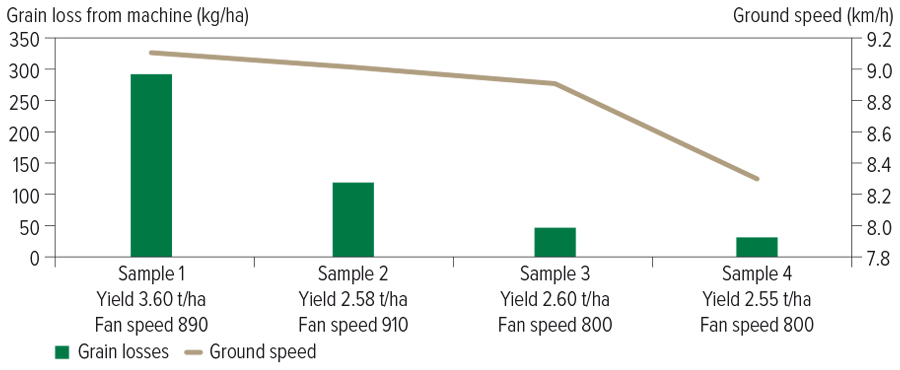

Table 1 shows an example of the harvest efficiencies measurements at the Facey site and Figure 3 shows harvest loss assessments taken for the Liebe site. Harvest rate (hectares per hour) were higher when using a stripper front with more economic fuel use.

“Harvesting faster and taking in less material does mean that header settings should be adjusted accordingly to avoid high harvest losses. Machine (back) losses generally occurred when fan and sieve settings were not adjusted to suit a reduced amount of chaff flowing through the machine.

“Front losses were high when whole heads dropped to the ground. Harvesting too low, often due to uneven crop height, exacerbated this result.”

Table 1: Yield and harvest operational measurements for the Facey site.

Treatment | Yield (t/ha) | Speed (km/hr) | Fuel use (l/hr) | Harvest rate (t/hr) | Harvest rate (ha/hr) | Economy (l/t) |

|---|---|---|---|---|---|---|

Draper (spread) | 3.42 | 7.03 | 111.38 | 29.01 | 8.58 | 3.85 |

Stripper (windrow) | 3.33 | 7.83 | 100.49 | 31.43 | 9.54 | 3.20 |

Stripper (spread) | 3.25 | 8.39 | 87.02 | 33.08 | 10.22 | 2.63 |

Source: Liebe Group

Figure 3: Machine harvest losses assessed at different ground speeds and different fan settings at the Liebe site.

Source: Liebe Group

As the project progresses, the pros and cons of tall standing stubble systems will be documented and quantified to generate a risk and reward matrix for the systems to inform growers’ decisions. An initial list is presented in Table 2.

Table 2: Preliminary list of pros and cons of retaining tall stubble based on grower and researcher observations.

Pros | Cons |

|---|---|

Equipment used to create tall stubble can increase seeding and harvesting efficiencies | Harvest losses can be higher if machinery settings are not adjusted |

Greater moisture retention achieved when combined with speed tillage | Weed control can be challenging due to reduced spray efficacy and harvest weed seed capture challenges |

Less wear and tear on machinery as it processes less straw | Mice control can be challenging |

Less soil disturbance, which reduces weed germination | Can be a challenge to match harvesting and seeding equipment |

Less erosion | Potentially increased disease load |

More flexibility in time of sowing | Increased frost risk |

Stubble cover creates cooler soil at seeding | Sowing into tall stubble can be problematic, causing issues with hairpinning and bulldozing |

Improved fuel efficiency | Reduced soil disturbance can exacerbate non-wetting soil issues. |

Increased competition and shading out of weeds | Possible nitrogen ‘tie-up’ with extra stubble load |

The 2023 trials will have additional measurements for temperature, soil moisture and nutrient tie-up taken across all sites to add further insights into the risks and rewards of different stubble management systems.

More information: Chris O’Callaghan, chris@liebegroup.org.au