Technical innovations and region-specific constraints have combined to create a need for local workshops on spray application technology and drift mitigation.

Hands-on training attracts strong WA grower interest

By Bill Campbell, Agronomist and spray application specialist, CampbellAg

During 2020–23, GRDC invested in workshops instructing grain growers on best-practice sprayer set-up and broadacre cropping application techniques. The primary target audience was Western Australian grain growers, their employees and other industry people, such as agronomists and consultants. Younger grain growers and farm employees in particular were encouraged to attend.

The workshops used face-to-face training, on-farm, with growers’ own spray machinery. A minimum of two sprayers (standard nozzle sprayer and pulse width modulation) were used during the workshops. Where possible, multiple batching plant/mixing systems were used.

Locations were spread across WA’s broadacre grain growing regions with local assistance. A post-workshop survey was incorporated into this investment to measure subsequent grower practice change.

Key focus areas included:

- Sprayer calibration – the basics of coverage from droplets and water volume through to nozzles and setting up the sprayer. A process was provided to help growers calculate flow rates, pressures and nozzle selection; and

- Spraying efficiency – mixing and batching processes and equipment. Interest in this topic resulted in additional GRDC investment to produce a booklet titled Mixing and Batching for Agricultural Chemical Application, the first publication of its type.

A total of 677 attended the 20-workshop series, with 95 per cent of participants being growers, managers or employees. A majority – 66 per cent – had not previously attended a spray application workshop.

Participants had many different subjects of interest, resulting in every workshop having its own flow and dynamics depending on the region. As the workshop program was rolled out, content was modified to cater for seasonal conditions, such as summer rains, interest around Delta T, night spraying, plant stress considerations and adjuvants.

With water supply issues occurring in the Great Southern and eastern districts in 2021, water quality and supply became a key additional topic.

The 2021 season also highlighted drift issues, which allowed a focus on a new pre-emergent herbicide – with drift on to lupins a particular focus area of concern. The 2022 and 2023 workshops further targeted areas in WA that were previously under-serviced by spray training or extension workshops.

Survey responses showed that two out of three participants had not attended any similar type of spray training before. Instead, they accessed multiple sources of information that can be grouped into chemical reseller/agronomist and internet/GRDC resources. Feedback was positive and interest was high for most topics covered.

The project also highlighted that spray application extension is often overlooked compared to herbicide efficacy, weed resistance, soils and nutrition. Spray application equipment requires capital investments of hundreds of thousands of dollars. Services that support best-practice spray applications stand to drive substantial on-farm gains.

The Mixing and Batching for Agricultural Chemical Application publication produced as a result of this workshop series is available as hard copy or for download at the GRDC website.

Additional resources can be found on the GRDC website.

More information: Bill Campbell, [email protected]

Northern region spray day initiative

By John Cameron, Independent Consultants Australia Network

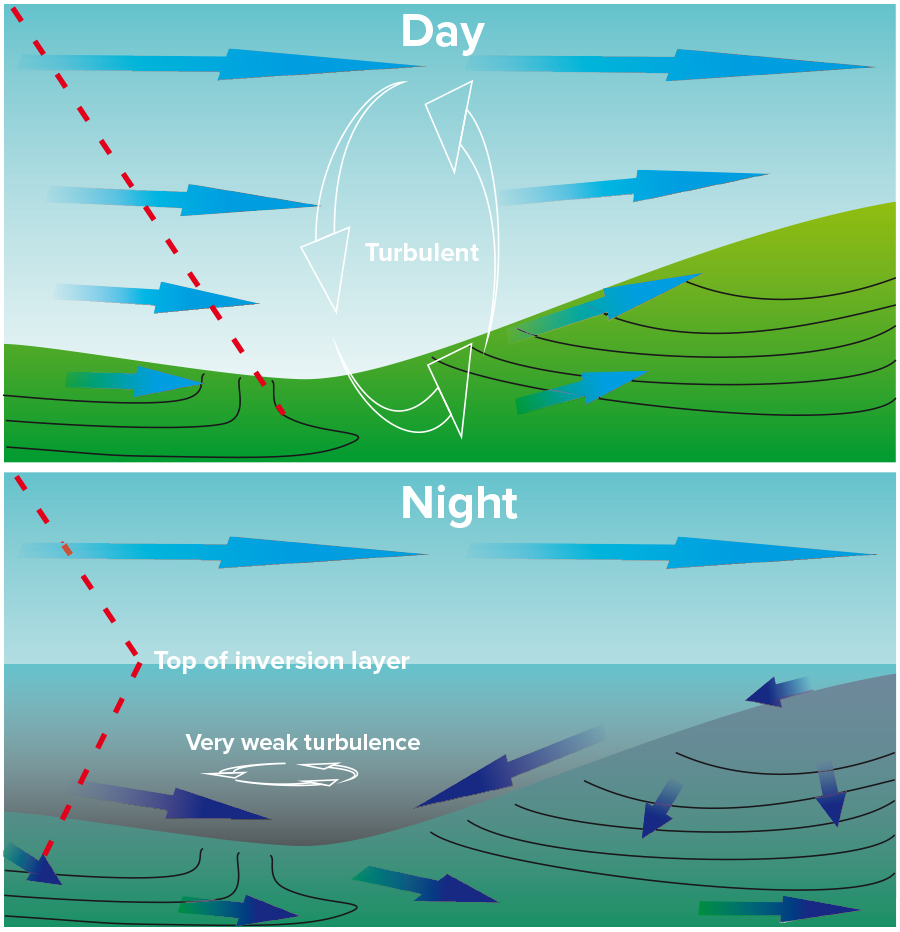

In the northern region, the high frequency of hazardous inversion conditions and the proximity of drift-sensitive cotton crops means that drift mitigation is a key consideration for how and when to spray. Applications during hazardous surface temperature inversions can lead to spray drift and damage to off-target crops kilometres away (see Figure 1).

Figure 1: Typical vertical temperature profiles during the day and night and their different propensities for creating an inversion layer.

GRDC Factsheet

Hazardous inversion conditions can form and dissipate at any time of night commonly occuring from an hour before dusk to an hour after sunrise. This has resulted in regulation that prohibits pesticide application during a hazardous inversion.

To help growers in parts of the northern region meet this regulatory requirement, an inversion drift hazard warning system has been established. The system draws on meteorological data captured by the Weather and Networked Data (WAND) tower network. WAND is the result of six years of collaborative research by GRDC and the Cotton RDC and has been delivered in partnership with Goanna Ag.

WAND delivers up-to-date weather data every 10 minutes reporting the Absence or Presence of a Hazardous inversion. The data can be accessed on the Goanna Ag website.

The system forecasts the likelihood of an inversion forming within the next two hours, which allows operators to make decisions around completing the current load and/or refilling and continuing to spray.

To help growers familiarise themselves with this decision-support tool, GRDC invested in a series of workshops delivered by Independent Consultants Australia Network. This NGN-driven project has delivered six GRDC industry spray days across the northern region during 2022-23.

These events provided a platform for communicating the latest developments in both spray application technology and stewardship. The format involved presentations from researchers followed by inspections of new technologies and hearing from technology developers.

The investment will also assess the value growers and industry partners obtain from these activities and, where possible, the rate of adoption of best spray and chemical management at the farm level.

To further assist growers, several technical resources have been developed to promote the adoption of best spray and chemical management. These include:

- GRDC Spray Drift webpage

- Spray drift hazard warning system

- Cotton Australia Spray Drift and Satacrop

- GRDC Hazardous Inversion Fact Sheet

- The GRDC 'Weather essentials for pesticide application' booklet

- The GRDC 'Meteorological principles influencing pesticide application' booklet

- The 'Killing glyphosate resistant ryegrass? Application does matter' paper

- GRDC Grains Research Update online

- A playlist of Cotton Info videos on pesticide application.

More information: John Cameron, [email protected]