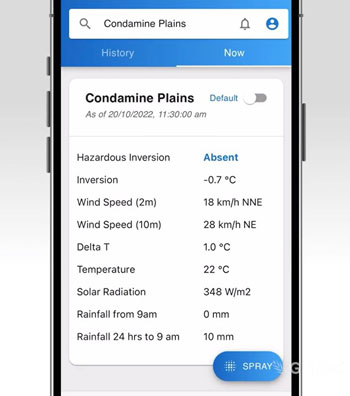

By simply logging into an app, the important difference between a hazardous and non-hazardous inversion can be established, taking the guesswork out of timing pesticide spraying.

Until this year, there was no way to distinguish between inversions, so they all had to be treated as hazardous – with potential for spray drift.

Now, thanks to six years of collaborative research, spray applicators are able to log in to a new decision-support tool called WAND – short for Weather and Networked Data.

In real-time, it measures several weather parameters. Importantly, it uses novel technology that detects hazardous temperature inversions and has a two-hour predictive function, called Nowcast.

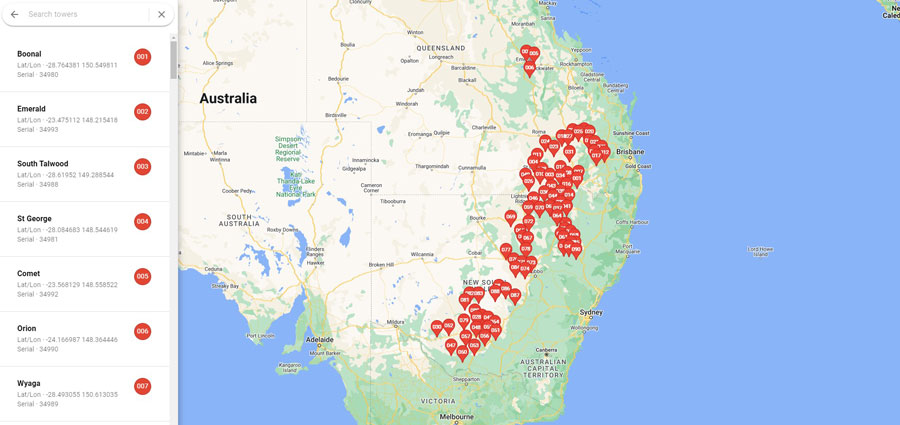

The WAND app shows where inversion towers are located so growers can choose the one most relevant. Photo: Goanna Ag

The technology is the result of investment by GRDC and the Cotton Research and Development Corporation (CRDC). The RDCs have partnered with Goanna Ag to build and maintain a network of 100 WAND towers throughout grain and cotton growing regions in central and southern Queensland and NSW.

Growers and spray applicators have rapidly adopted the technology. More than 1500 users have registered since the launch in mid-November 2022.

Under the $5.5 million investment, the network provides real-time data that identifies and measures the presence of hazardous temperature inversions.

The WAND app shows if an inversion is occurring so spraying decisions can be made. Photo: Goanna Ag

The WAND app shows if an inversion is occurring so spraying decisions can be made. Photo: Goanna Ag

The free network is available to all growers and spray applicators and can be accessed via a web browser on smartphones, tablets and computers.

Breeza grower James Pursehouse has been using WAND as an additional tool to check whether it is safe to spray.

“During the summer months, the spraying window is limited, and you want to spray when it’s cool, often in the early morning. But this is when there is more chance of an inversion occurring,” Mr Pursehouse says.

“Now you can easily check the app on your phone to determine if there is an inversion and if it is hazardous.

You still need to check other spray parameters before turning the key but WAND definitely takes the guesswork out of determining hazardous conditions,” he says.

GRDC chemical regulation manager Gordon Cumming says WAND is providing critical data to support planning and spraying operations. For example, its nowcasting ability – providing a two-hour prediction on the presence or absence of a hazardous temperature inversion – helps plan jobs.

“The nowcast is being updated every 10 minutes and takes the guesswork out of whether to start a job, refill tanks once a job has started, or knock off until conditions improve,” Mr Cumming says.

Overall, WAND eliminates uncertainty, so better spray decisions can be made.

A WAND inversion tower. Photo: Goanna Ag

A WAND inversion tower. Photo: Goanna Ag

“Pesticides are an important component of modern farming and play a major role in maintaining high productivity. Yet, unintended spray drift remains an issue. When spray droplets are captured and transported in hazardous temperature inversions, these compounds can affect agricultural enterprises and other sensitive areas tens of kilometres away from the site of application,” Mr Cumming says.

With no easy way to determine whether inversions exist, growers and spray operators often rely on environmental cues.

This could mean checking to see if there is smoke or dust hanging in the air or if distant sounds are becoming clearer and easier to hear.

“Ultimately, guesswork will lead to some believing that they are okay to spray when in fact conditions are at their most hazardous.”

Mr Cumming says it is important that the usual best-practice methods are followed. “I really want to emphasise the need for all spray operators to follow all label directions, monitor and record weather at the site of application, use appropriate nozzles to provide the required spray quality (in other words, very coarse) and to operate at appropriate ground speed and boom height.”

WAND Q&A

Why is it needed?

The off-target movement of both herbicides and pesticides – referred to as spray drift – is a particularly acute problem in mixed-cropping regions where a diverse range of chemicals may be applied at any given time. Research has found that unsuitable spraying conditions can result not only in unintended damage to non-target crops, but up to 50 per cent of applied pesticide may not even reach the target.

What are the benefits of using WAND?

WAND takes the guesswork out of spraying by providing clear, real-time data to support your decision on when to spray based on the presence or absence or a hazardous surface temperature inversion.

What is an inversion?

A surface temperature inversion occurs when the air temperature increases with height, leading to a layer of cool, dense air being trapped below warmer air close to the ground. Inversions exist most nights from an hour before dusk to an hour after sunrise. But knowing whether an inversion is hazardous first requires knowing whether one is present and, second, the wind flow conditions and turbulence level within the inversion.

What makes an inversion hazardous?

An inversion becomes hazardous if there is insufficient turbulence resulting in spray droplets being suspended in the inversion layer and then transported by laminar winds. Laminar winds are the opposite of turbulent winds. They are smooth and streamlined.

In turbulent conditions, the air mixes at different levels, allowing droplets to be deposited onto their intended target.

Laminar winds are known to be associated with long-distance and widespread damaging spray drift, capable of transporting droplets in high concentrations for long distances across the surface.

When a hazardous inversion has been established, it acts like a barrier. It isolates the inversion layer from the normal weather situation, especially the normal wind speed and direction.

Sprays applied in these conditions can become trapped in this cool air layer where there is insufficient turbulence to either deposit or disperse the suspended spray droplets.

This lack of turbulence results in the transport of drift over long distances in localised laminar air flows that are often in different directions to those indicated by the general synoptic (weather pattern) winds.