Key points

- Soil amelioration’s greatest advantage is when subsoil moisture is required to finish a crop

- Amelioration is an expensive process with significant engineering challenges, and uncertainty about how much change is needed, meaning it must be targeted and strategic

- Amending a soil is a capital investment, where soil is the capital asset

- This project is tackling both surface and subsoil constraints with the aim of providing a framework for profitable amelioration decisions based on soil constraint variability and return on investment.

In poorer seasons where subsoil moisture is required to finish a crop, the benefits of soil amelioration shine through. This is one of the findings from the first year of a major GRDC investment into transforming soils across the northern region.

The soil amelioration project tackles both surface and subsoil constraints but is finding the biggest yield gains are coming from subsoil improvements.

Led by the University of Southern Queensland’s (USQ) Professor John McLean Bennett, with trial site management by the Queensland Department of Agriculture and Fisheries (DAF) and the University of New England (UNE), the project is focusing on the major constraints within the region – compaction and/or dispersive soils.

Ameliorating them fully is an expensive and time-consuming process. With significant engineering challenges, supply logistics and energy requirements, the ultimate aim is to determine the threshold for ‘do-nothing management’.

Professor Bennett says this is the point where investment is no longer sensible. “We do not want growers investing in marginal gains. Amendment must be site-specific, and spatially targeted at the soils most likely to respond.”

Presenting the first year’s findings at GRDC northern region Updates, USQ’s Dr Stirling Roberton and DAF soil specialist Dr David Lester said the main question to be answered was: “Can the soil profile be re-engineered so that it is not constrained either physically or chemically? And, if we do that, what does water-limited yield look like?”

This led to other questions, including:

- What is the return on investment from soil amelioration?

- How should hectares across farms be targeted to offer the best potential for yield improvement?

- Should dispersive soils be tackled in the surface, the subsurface or both?

- What amendments other than gypsum can be used?

- How does the associated physical disturbance affect crop performance?

- What impact does a nutritional strategy have on yield outcomes?

Dr Roberton said physically dispersive soils can decrease both soil water availability and nutrient acquisition, increase the risk of runoff and erosion, and impair biological activity. “In many regions where yield is constrained, dispersive soil within the surface 50 centimetres and deeper is often present.”

These soils have historically been referred to as sodic soils, but the term ‘dispersive’ is more appropriate. “It is a direct measure of the mechanism constraining the soil via decreased structural stability, compared to an exchangeable sodium percentage (ESP), which is a measure of sodicity – not all sodic soils disperse because other factors can keep them stable.

“We have found soils with an ESP of 26 that do not disperse. They will not get any benefit from gypsum application as they are already structurally stable.” As a general rule, he said, an aggregate stability test should be used before undertaking major amelioration work.

Within the project, other related constraints including acidity, alkalinity, salinity and nutrients are considered as compounding and/or interacting factors.

Trials

Six experiments have been established across Queensland and New South Wales with 13 treatment combinations to test how surface (zero to 20cm) and subsurface (20 to 50cm) amelioration strategies can be deployed to remove soil constraints.

The trials, three in Queensland and three in NSW, tested:

- surface gypsum rates calculated to reduce ESP to three per cent;

- subsurface gypsum rates to reduce ESP to three per cent in half the soil volume (Queensland) and a quarter of the soil volume (NSW);

- ripping to 20cm, and deeper where possible;

- nitrogen, phosphorus and potassium applications into the soil profile at 20cm depth; and

- subsurface organic amendment applications.

Dr Lester said the gypsum rates, often more than 15 tonnes a hectare, were compared against a high-rate feedlot compost (at 20cm deep) in Queensland and against lucerne pellets in NSW at about 10t/ha. Elemental sulfur applications were also tested as a way of dissolving calcium carbonate to produce gypsum in-situ and lower alkalinity – a very experimental technique in the region.

“The rates applied were calculated on each site’s specific soil properties and were theoretically sufficient to permanently address soil constraints throughout the zero-to-20cm soil profile, starting the process in the subsoil 20 to 50cm to achieve a capital improvement.”

Dr Lester said applying lower rates would not adequately address constraints, essentially becoming a wasted product. “These rates are very high and is why soil amelioration must be considered a capital investment and only attempted on the hectares that offer the best potential.”

Dr Roberton agreed. “Most highly constrained soils require significant capital investment, particularly when you consider the cost of deep ripping for compaction combined with high rates of amendment application required to fix dispersive soils.

“Realistically, the decision point is: ‘Do I grow my farming business by purchasing more land, if it’s even available, or do I grow it by investing in the hectares already owned?’

“This is really the economic question being asked.”

As an example, the Millmerran, Queensland, trial could be considered a substantial investment. That said, yield increases were recorded, increasing by up to 25 per cent or 0.75t/ha.

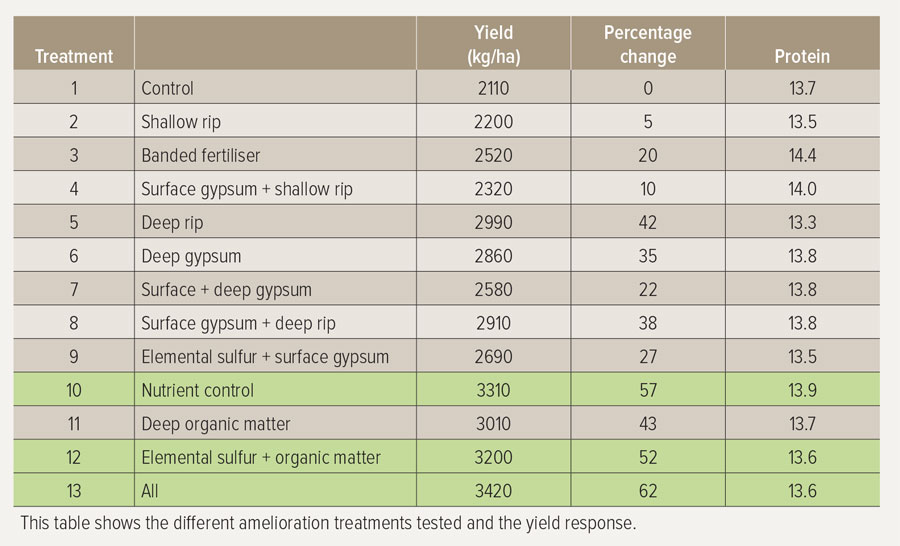

At Drillham, also in southern Queensland, grain yields increased up to 60 per cent or 1.25/ha (Table 1).

Three treatments in particular provided the largest increases (see treatments 10, 12 and 13).

These treatments all had tillage to 30cm, and either had high nutrient supplies from the high nitrogen and phosphorus rates (treatment 10), or the composted feedlot manure (12 and 13). Deeper ripping (to 30cm) and lower nutrient inputs increased yields by 0.8t/ha (40 per cent), but it appears the higher nutrient supply plots allowed greater yields to be recorded, he said.

Table 1: Relative grain yields for wheat with various treatments at Drillham, Queensland.

Source: Dave Lester

Ripping

Both researchers were also keen to point out that ripping can reduce compaction and improve water-holding capacity. However, any benefits in dispersive soils will be short-lived unless simultaneously addressed with gypsum and/or lime. Nutrient needs must also be addressed after ripping.

“It is worth considering that the cost in diesel of ripping to depth without adding the necessary amendment is unlikely to be recovered,” Dr Lester said. “Repeated, smaller gypsum or organic matter applications coupled with deep ripping is cost-prohibitive. Hence, single, large additions may ultimately be best practice for subsoil applications. These are some of the factors we are working at exploring in the research.”

Importantly, the areas where soil amelioration is not economically viable due to constraint severity need to be identified. In these areas, the best outcome could be to drop back inputs and manage to the constraints, or potentially return to pasture.

Logistical challenges

With such large amounts of product required, Dr Lester said, it was logistically challenging to source, transport and apply treatments at each site, especially with deep applications.

There are also engineering challenges involved. “Applicators are not going to be universally capable machines for putting ameliorant at depth. It is very challenging to engineer something to measure and distribute all manner of materials. The deep placement machine used in Queensland required the soil amendments to be relatively fine and easily flowable, in order to be metered and delivered to depth.”

This was achieved by using six-millimetre screened feedlot compost and air-drying natural mined gypsum to reduce moisture content. All materials were screened at the top of the applicator bin through a 12mm screen to further exclude lumps.

In NSW, flow problems were resolved by using pellets and prills – a more expensive solution. Metering of products was achieved through fluted rollers.

Future

The results are from just one year and the team said the 2021 crop would give a better indication of the long-term effects of treatments, under more typical conditions. “It was a very wet summer and autumn, which allowed all plots to refill after treatment application. The Talwood site, however, was planted again in mid-January 2021.”

After delivering substantial yield increases in the first year, it would now be important to see how consistently any increases can be achieved. “What we do know is that blanket-rate applications are not the answer,” Dr Roberton said.

“It is simply not economically feasible for these large soil amelioration capital investments. We need to make sure we diagnose soil constraints accurately and only invest in the hectares that offer the best potential for improvement.

“Growers should be focusing now on getting their yield maps calibrated and consistent, as well as investing in adequate soil sample analysis, to help themselves target constrained areas. The important thing to note is that it is the soil sample analysis that drives accurate amendment prescription, limits financial wastage and optimises return on investment.”

This project is part of a series of linked investments that are assessing the economics of ameliorating constrained surface and subsurface soils in the northern region.

The program has four areas covering spatial soil constraint identification, amelioration and management of soil constraints, the economics of adoption, and an overarching communications and extension program.