Key points

- Mechanical amelioration of constrained soil generally leads to improved crop performance, but little is known about the soil’s changed nutrient status

- Research is underway to develop fertiliser guidelines for these ameliorated soils

- Preliminary results show that ameliorating water-repellent soil is improving potassium availability

Although mechanical soil amelioration is successfully alleviating multiple soil constraints across Western Australia, some significant knowledge gaps have emerged.

An integrated research program, supported by GRDC and led by the Department of Primary Industries and Regional Development (DPIRD), is set to fill these gaps and update guidelines for fertiliser recommendations for these ameliorated soils by 2022.

DPIRD is working with the University of Western Australia, Curtin University and CSIRO through the SoilsWest Alliance, bringing together expertise in field crop nutrition, soil nitrogen processes, geostatistics and geophysics. This broad skills base will allow the team to gain an understanding of how soil amelioration is changing soil nutrient supply and demand at the plot and paddock scale.

Questions being addressed

Mechanical soil amelioration is undertaken with mouldboard ploughs, rotary spaders, disc ploughs and deep rippers. All of these mechanical approaches introduce spatial variation in soil properties – most likely changing soil nutrient supply and root growth – and change crop demand, which raises some important questions:

- How do different implements redistribute soil nutrients within their working depth?

- How do we sample an ameliorated soil so as to best predict fertiliser requirements?

- Does a change in spatial distribution of nutrients actually lead to a difference in plant availability of these nutrients and how do we predict this?

- What is the amount of soil organic matter decomposed in the short term (less than two years) and how does this influence soil nitrogen supply in response to soil amelioration?

- How does mechanical soil amelioration change the yield response to applied nutrients?

Preliminary results

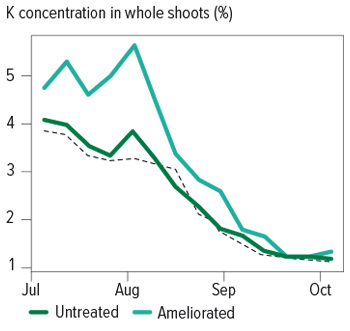

Figure 1: Shoot potassium concentration in a wheat field trial at Gibson, Western Australia, in 2019. Dashed line shows the critical level for the growth stage observed in each measurement.

Source: DPIRD

Research is showing that ameliorating soil water repellence is improving the availability of soil potassium. Weekly measurements of shoot growth and nutrient concentration at a trial in Gibson showed shoot potassium concentration was well above critical levels in the ameliorated soil in early growth stages, but was close to critical levels in the untreated soil at all sampling times (Figure 1). Higher uptake of soil potassium has also been observed at other sites where amelioration of soil water repellence has been undertaken.

Deep ripping has changed the yield response to surface-applied nutrients. On a compacted grey, deep sandy duplex, deep ripping increased the response to nitrogen in the second year after deep ripping. On a compacted deep, grey sand with very low soil potassium levels, deep ripping alone did not increase wheat grain yield, but deep ripping combined with applied potassium did.

Field trials with deep placement of nutrients have revealed some interesting results. The effect of deep-placed nutrients is linked to subsoil nutrient levels; the largest response (17 per cent) to deep-placed phosphorus was at a site where subsoil Colwell phosphorus levels were less than five milligrams per kilogram below 30-centimetre depth. However, at two sites were there was no significant yield response to deep placement of nutrients, there was an increase in grain protein. These trials are continuing and the ongoing effects will be monitored.

More information: Dr Craig Scanlan, craig.scanlan@uwa.edu.au, 08 9690 2174