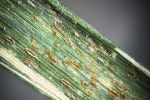

When drought-affected sorghum faced the threat of being blown over by Tropical Cyclone Oma and other recent storm fronts, some of the northern region's sorghum growers made the decision to harvest early.

As a consequence, the sorghum had higher-than-usual moisture content.

Even without the threat of cyclonic conditions, more and more growers are moving towards an earlier harvesting date for both summer and winter grains - a decision that means grains have high moisture contents.

Post-harvest grain protection specialist Philip Burrill, a Queensland Department of Agriculture and Fisheries (QDAF) senior development agronomist, says the move to earlier harvesting highlights the need for moisture management and, with that, effective aeration and drying systems.

With sorghum, for example, receival standards dictate moisture content of 13.5 per cent.

"For northern region sorghum growers, it is quite common for later-planted sorghum to be harvested at 14 to 16 per cent, as ambient conditions in late March, April and May typically result in a very slow dry-down for sorghum sitting in the paddock," Mr Burrill says.

"Also the practice of 'early harvest' is becoming more common as growers wish to reduce the risk of grain losses in quality due to sprouting or physical loss from lodging and storms."

Mr Burrill says options to deal with higher-moisture grain in storage include:

- Holding the wet grain safely using aeration cooling fans, run continuously at low airflow rates of two to four litres of air, per second, per tonne of grain (2 to 4L/s/t). With care, this is a safe practice for three to six weeks before drying or blending.

- Blending high-moisture grain with low-moisture grain, then aerating it to give moisture uniformity in the grain bulk.

- Hot air drying. This includes either: (a) continuous flow drying, where grain is transferred through a dryer, which uses a high volume of heated air to pass through the continual flow of grain; or (b) batch drying, where a fixed or transportable dryer is used to dry batches of 10 to 20 tonnes of grain at a time with a high volume of heated air. The air passes through the grain and out perforated walls.

- Aeration cooling and drying, where grain of moderate moisture (14 to 16 per cent), is held for a short term under continuous aeration cooling until aeration drying is ready to start. In the drying process, large volumes of ambient air are used to force a drying front through the grain in storage which slowly removes moisture.

In a few coastal locations, or where ambient air conditions remain at high relative humidities during the day, supplementary heating can be added to assist with aeration drying.

More information can be found in the GRDC Fact Sheet, How aeration works.

Different processes

Mr Burrill says it is important to understand that there are large differences between aeration cooling and aeration drying. The two processes require significantly different airflow rates and fan run times to achieve either cooling or drying.

"Aeration cooling fans have a flow rate of 2 to 4L/s/t, which in most cases achieves very little in the way of drying," he says.

"At best, it may see a drop of 0.5 per cent in moisture content.

"These very low airflow rates do a poor job when reliable grain drying is required."

In contrast, larger drying fans have airflow rates of 15 to 25L/s/t.

"The secret to aeration drying is to have long fan run times each day, say 18 to 22 hours, to push dry fronts rapidly through the whole depth of the grain," Mr Burrill says.

He adds that the task is made more efficient if an automatic aeration controller, which has the ability to switch on to a drying operation mode, is used.

"When using this equipment, there are two stages to the drying operation," Mr Burrill says.

"In stage one, the automatic controller is set to run the fans to use all available ambient air with a relative humidity under 75 per cent for five to seven days.

"In stage two, the parameters are tightened and the setting changed to use all available air under 65 per cent relative humidity.

"Remember it is the 'average' relative humidity of the ambient air used throughout each day that is important for effective grain drying."

Mr Burrill says it is important to also carry out regular checks of grain moisture at a few locations in the storage to ensure grain is not over-dried.

"Be aware that once the aeration drying process is well underway, grain at the bottom of the silo, where the air first enters, will always be drier than grain at the top of the silo."

Once the desired grain moisture content is achieved, the high airflow drying fans can be turned off and sealed off, allowing the smaller cooling fans to be turned on to reduce grain temperature for safe storage.

Mr Burrill's top aeration-drying rules include:

- Using high airflow

- Long run times

- Keeping grain bed depth shallow, where possible.

"High airflow rates and shallow grain-bed depth ensures that the moist air exits the grain before it reaches 100 per cent moisture saturation," he says.

"If harvesting a lot of high-moisture grain, it can be tricky to have enough storage space to only half-fill silos.

"If grain can be kept to less than six metres deep, it does make the aeration drying operation simpler."

Harvest implications

The shift towards an early harvest is also impacting on the way growers store grain and how companies in the post-harvest storage industry innovate.

For example, Mark Conway, from Toowoomba-based aeration company Control Unlimited, says the shift to more growers harvesting over-moisture grain has led his company to work towards automating its aeration controllers.

"We are seeing more over-moisture grain being harvested for many reasons, and more silos being set up for aeration drying," he says.

"We have catered to this market up to now with semi-manual drying software and with operational advice on how best to equip silos and when to operate the fans.

"The demand is such now that the next obvious step is to automate the process."

Mr Conway is conducting on-farm research with growers in the region.

"The aim is to fine-tune our software by using it in 'real world' applications," he says.

"We want to gather feedback from both the controller operation and actual grain temperature and moisture, which we will get from in-silo mounted sensors."

Mr Conway and Mr Burrill say the benefits of aeration are well-known and accepted.

The northern grains region is historically ahead in uptake due to leading commercial aeration equipment suppliers and DAF staff who, over a number of years, 'have all been able to advise on use and benefits', Mr Burrill says.

It is a move that has seen growers reduce production losses from weather damage and lodging.

"In the past, when they had minimal farm storage capacity, growers had very few options around harvest time as depots were unable to take in higher-moisture-content grain," Mr Burrill says.

"The Australian industry should see reduced grain losses with the increased adoption of early harvesting and the increased knowledge of how best to manage this higher moisture content grain in farm storage."

More information: Philip Burrill, 0427 696 500, philip.burrill@daf.qld.gov.au; how aeration works and dealing with high moisture grain.