Key points

- Successful pest control in storages depends on combining regular grain monitoring, good hygiene, aeration cooling and correct fumigation practices

- Fumigation results rely on a gas-tight sealable storage to achieve the required gas concentrations and exposure times (C x T) to kill all insect pest life stages

- In larger silos (150 to 2000 tonnes) recirculating gases using a small fan during the fumigation ensures rapid, uniform distribution of phosphine gas

Delivering the right dose of phosphine to every last grain in the storage is essential to achieve effective fumigation.

To prevent the development of resistance in insect pests, it is essential to make sure that phosphine works properly first time, every time.

As the main fumigation chemical that growers use to control grain storage insect pests, phosphine plays an important role in combination with grain monitoring, good hygiene, aeration cooling and, when appropriate, grain protectants. But careful attention needs to be paid to the finer details to achieve effective fumigations and successful pest control.

Why gas-tight?

It is essential that fumigation fully controls each life cycle stage of storage pests: eggs, larvae, pupae and adults. This requires a given minimum gas concentration (C), for a specified length of time (T). If this fumigation exposure (C x T) requirement is not achieved throughout the storage space, it is likely the various insect life stages, such as eggs and pupae, will survive in the grain.

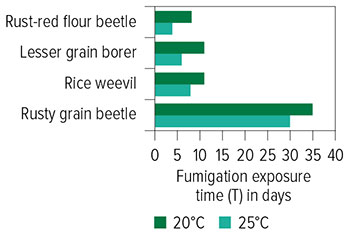

Figure 1: Phosphine fumigation exposure times at 360ppm required to control the full life cycle of strongly phosphine-resistant insect populations at 20°C and 25°C grain temperatures.

Source: Raj Jagadeesan

The phosphine fumigation C x T dose required to control all life stages of virtually all storage pest species is a minimum of 360 parts per million (ppm) phosphine gas concentration for 10 days at a grain temperature of 25°C (Figure 1).

Silos that are not sealed, gas-tight, during the fumigation period cannot achieve this minimum dose. When buying a new silo, select one that meets the Australian sealing standard AS2628. Also, conduct a pressure test on existing sealable silos to identify any leaks prior to a fumigation.

Repeating poor-quality grain fumigations in leaky, non-gas-tight silos not only gives poor results, but it also selects for insects with phosphine resistance genes. This eventually causes increased resistance in pest populations.

Storage insect pest populations in Australia include insects with both weak and strong resistance. About 10 to 11 per cent of storage pest populations collected from eastern Australian farms for resistance testing are strongly resistant. Except for rusty grain beetle, strongly resistant insects can still be controlled with correct fumigation practices using the recommended phosphine label rate (C x T) in a sealable silo.

Strongly phosphine-resistant rusty grain beetle (Cryptolestes ferrugineus), one of the flat grain beetles, can be controlled by fumigating with an alternative gas such as sulfuryl fluoride (ProFume®, Zythor®).

Fumigation adjustments

Aeration cooling protects grain in storage but also slows insect activity, which changes fumigation requirements.

Fumigation time increases by a few days as grain temperatures drop from 25°C to 20°C (Figure 1). As insect metabolism (internal activity) is slowed for each of the insect’s life stages, including eggs, additional fumigation time is required to ensure toxins can build to lethal levels in the insect’s cells to kill each life stage.

Phosphine labels specify a seven-day fumigation exposure time for grain temperatures above 25°C and 10 days for grain temperature between 15°C and 25°C.

During fumigation, phosphine gas is typically liberated over a period of four to six days from tablets or blankets.

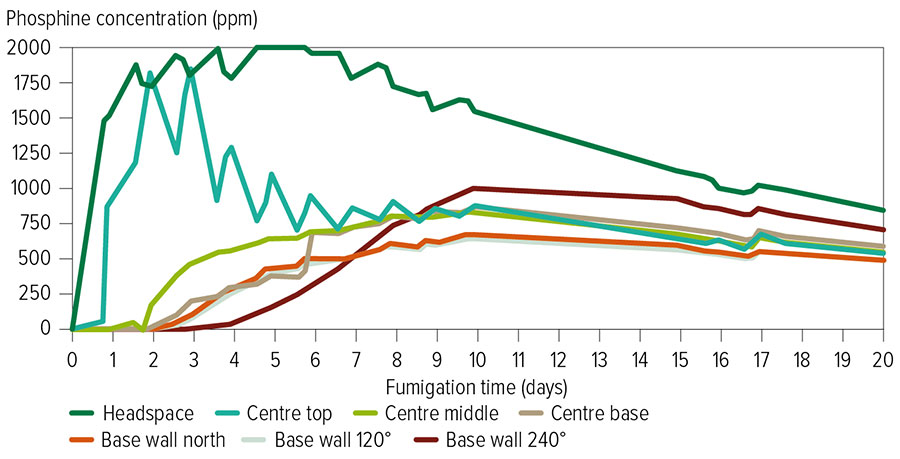

Phosphine gas moves slowly through grain – about six metres every 24 hours through cereal grain – meaning it can take two to five days to reach all areas within a medium to large silo (approximately 150 to 2000 tonnes, Figure 2). In large-silo fumigations, this may result in some grain, at the furthest distance from tablets or blankets, seeing a much-reduced phosphine gas exposure time (T). This is likely to result in poor control of the full life cycle, especially eggs and pupae.

A small fan can recirculate and rapidly distribute phosphine gas around larger silos during fumigation.

Figure 2: Phosphine gas levels at seven points in a silo during fumigation of 1420 tonnes of wheat, with five blankets hung in the silo top headspace. With no gas recirculation it took four to five days for gas to reach all grain at the silo base.

Source: Philip Burrill and Andrew Ridley

Keeping it safe

Check the product label for venting time. This is usually 24 hours if aeration fans are fitted to force a draught through the silo. It is usually five days for storages without fans, which rely on passive venting.

Storage enclosures and work areas need to be vented to below the time-weighted average (TWA) exposure standard of 0.3ppm for phosphine. Use fumigation warning signs and red and white safety tape on any storage under fumigation.

Using a small fan (0.37 kilowatt pictured) during fumigation to recirculate phosphine gave rapid uniform gas distribution in 1423 tonnes of wheat, resulting in 750ppm in all parts of the silo in just over one day. Photo: Philip Burrill.

Take the time to read the restraints and safety sections on phosphine product labels. For example, labels explicitly prohibit use in road transport vehicles, including a truck or road-hauled container. This is to prevent the practice of placing phosphine tablets in loaded grain trucks prior to delivery, which was common decades ago.

More information: Philip Burrill, 1800 WEEVIL, info@storedgrain.com.au